Parallel mechanism with two rotation degrees of freedom and one translation degree of freedom of space

A degree of freedom, translational technology, applied in the direction of manufacturing tools, metal processing machinery parts, large fixed members, etc., can solve the problems of limiting the rotation angle range of the end moving platform, uncertain mechanism accuracy, limited rotation angle, etc., to reduce power and Size, high precision machining capability, effect of reducing mass and inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

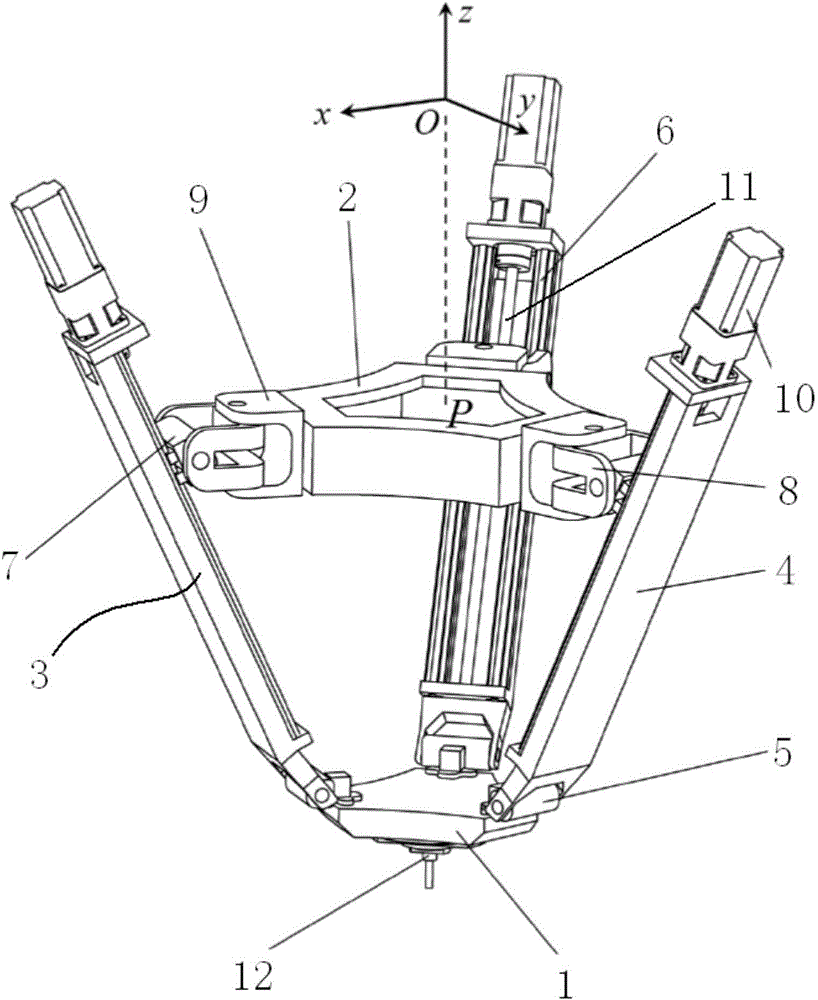

[0018] like figure 1 As shown, the present invention includes a moving platform 1 that is an equilateral triangle, a static platform 2 that is an equilateral triangle and three branch chains 3 connecting the moving platform 1 and the static platform 2.

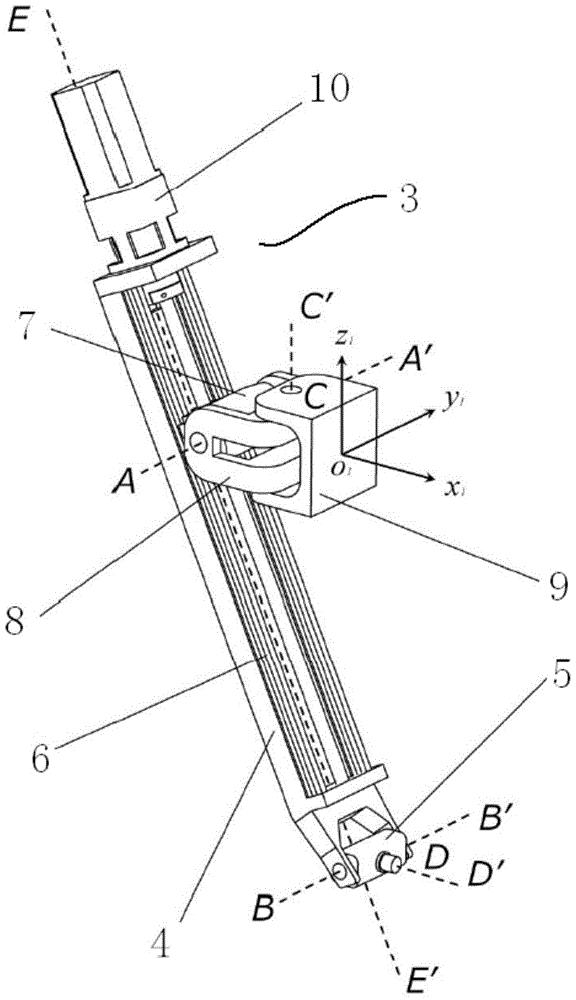

[0019] like figure 1 , figure 2 As shown, each branch chain 3 includes a connecting rod 4, and one end of the connecting rod 4 is connected to a corner of the moving platform 1 through a hinge 5 with two rotational degrees of freedom, and a straight line is arranged inside each connecting rod 4 As for the guide rails 6 , a slide block 7 is slidably arranged on each linear guide rail 6 . A driving device for driving the slider 7 to move on the linear guide rail 6 is also fastened to each branch chain 3 . Each slider 7 is connected to one corner of the static platform 2 through a hinge 8 with two d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com