A parallel mechanism with three degrees of freedom in space

A degree of freedom and parallel technology, applied in the direction of manipulators, manufacturing tools, program control manipulators, etc., to achieve the effects of simple branch chain structure, high rotation angle range, and guaranteed force balance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

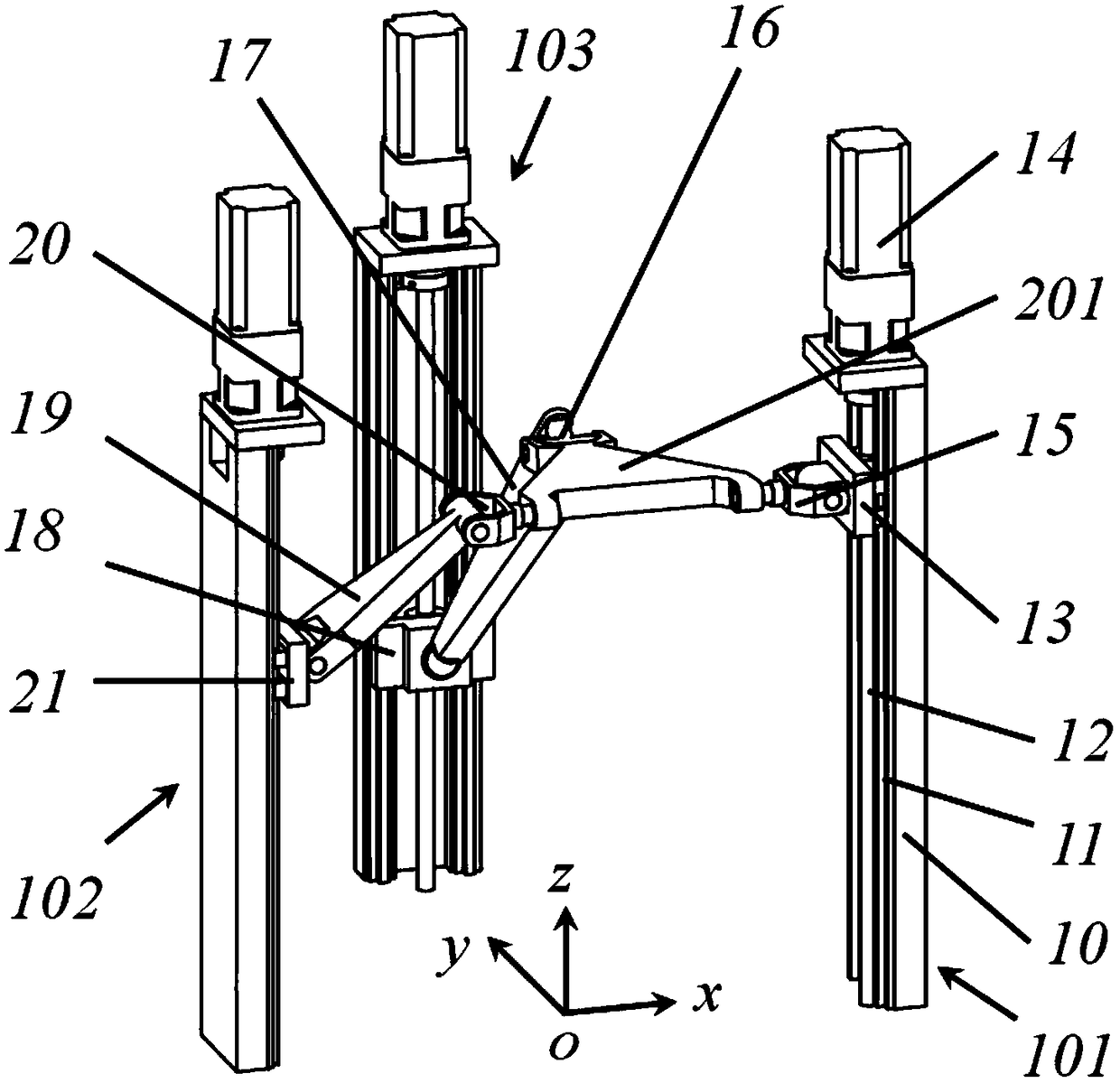

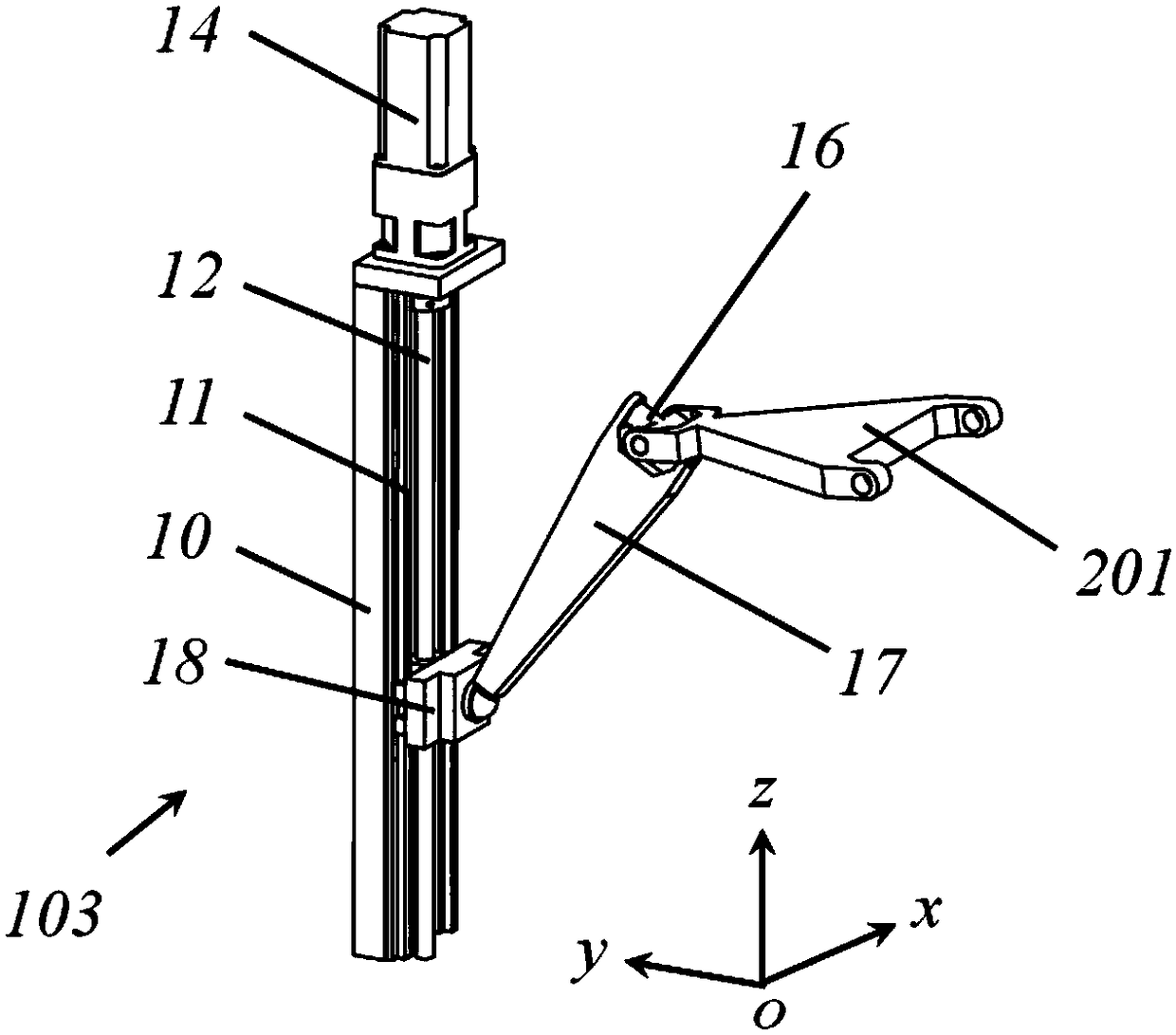

[0026] Such as figure 1 As shown, the present invention can be used in the schematic diagram of the spatial two-rotation-translational parallel mechanism of the five-axis linkage hybrid CNC machine tool, including the fixed frame 10, the moving platform 201 and the movement vertically arranged between the fixed frame 10 and the moving platform 201 according to the space Branch I101, kinematic branch II102 and kinematic branch III103. Each motion branch chain has a set of the same linear feed system, which includes a driving device 14, a linear guide rail 11 and a ball screw 12, wherein the driving device 14 and the linear guide rail 11 are fixedly arranged on the fixed frame 10, and the driving device 14 Drive ball screw 12 to rotate.

[0027] In the motion branch chain I101, the slider 13 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com