Connecting structure for car window inner decorative strip and sheet metal frame

A technology for connecting structures and interior trim strips, applied in vehicle parts, engine seals, doors, etc., can solve the problems of inconvenient connection, poor reliability, complex connection structure, etc., and achieve good decorative effect, reliable connection, and convenient connection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

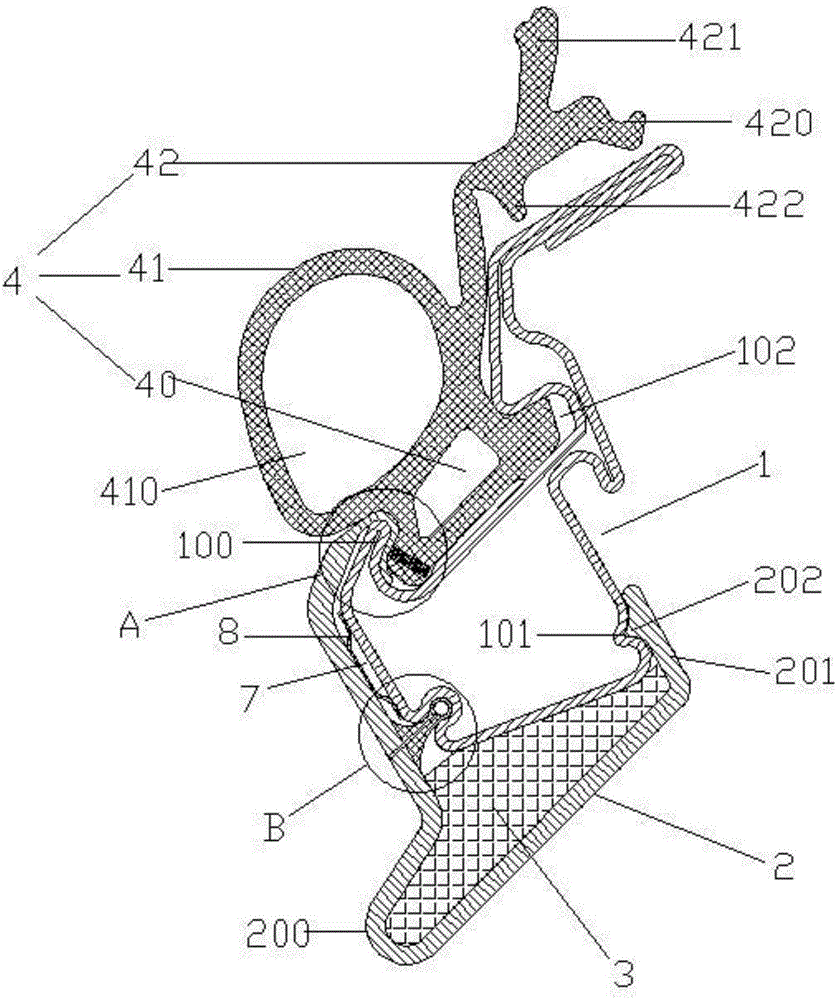

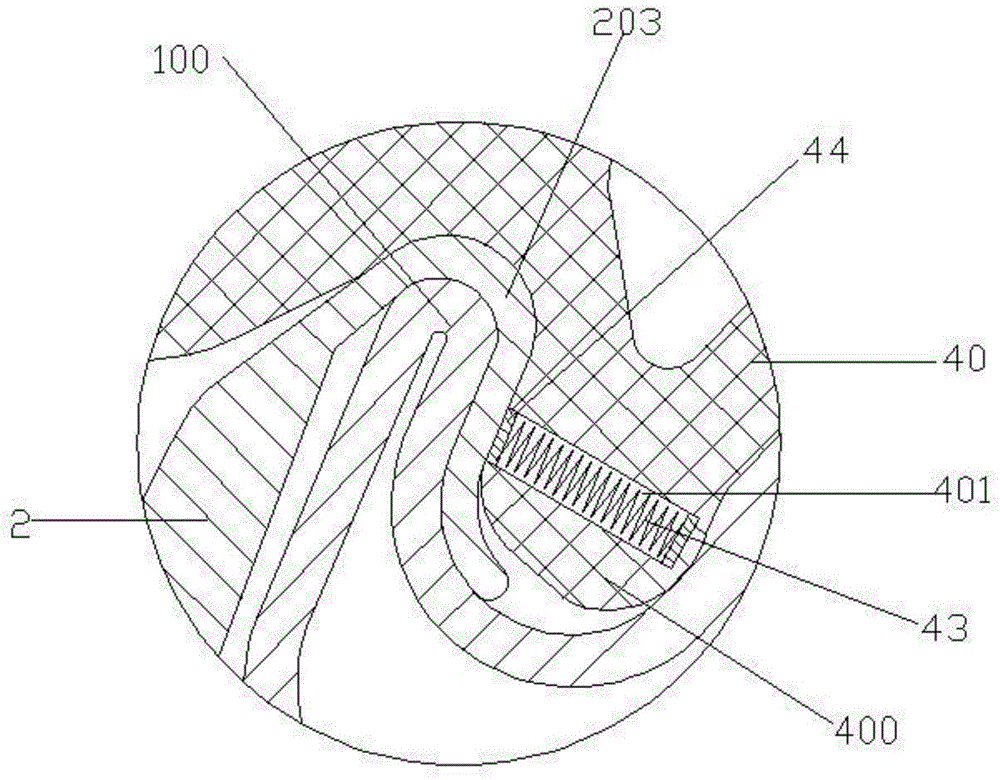

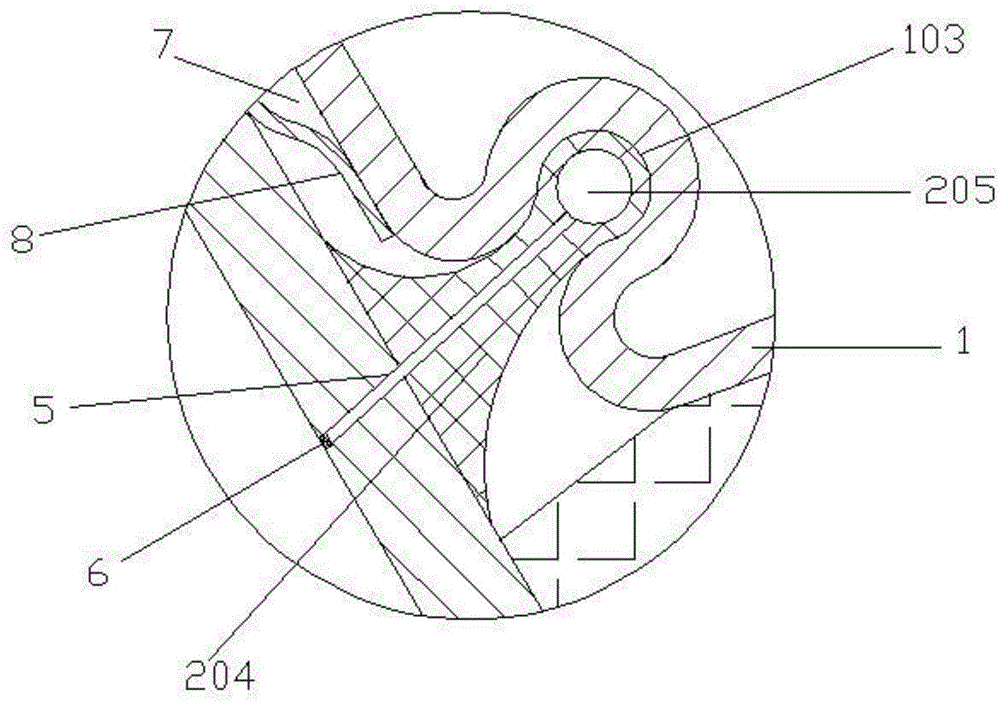

[0020] Such as figure 1 A connection structure between a window trim strip and a sheet metal frame is shown, including a sheet metal frame 1 and a window trim strip 2, and the middle part of the inner side of the sheet metal frame (left side in the figure) is bent and extended to form a convex eaves 100 , the lower end of the outer side (right side in the figure) of the sheet metal frame is recessed to form a card slot 101, the cross section of the window trim strip 2 is V-shaped, the bottom of the V protrudes to one side to form a eaves 200, the window trim strip 2 The cavity between the sheet metal frame and the sheet metal frame is filled with sponge 3, the outer opening of the window trim strip extends to form a retaining strip 201, and the inner side of the retaining strip 201 is provided with a raised strip 202 that matches the card slot. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com