Novel large-tonnage bridge girder erection machine and construction method thereof

A bridge erecting machine and a large-tonnage technology, applied in the new large-tonnage bridge erecting machine and its construction field, can solve the problems of construction load dispersion and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0100] Figure 20 The direction of the arrow in the figure indicates the erection direction of the construction method of the new large-tonnage bridge erecting machine.

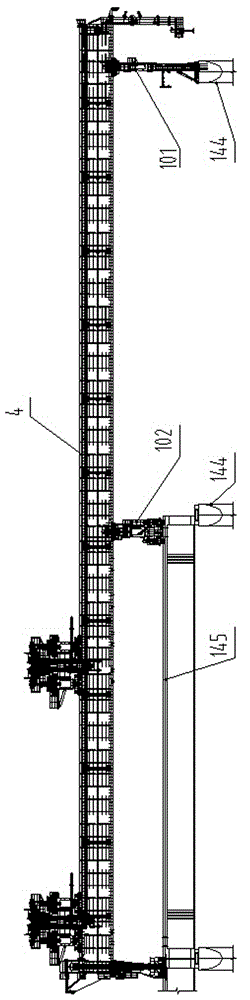

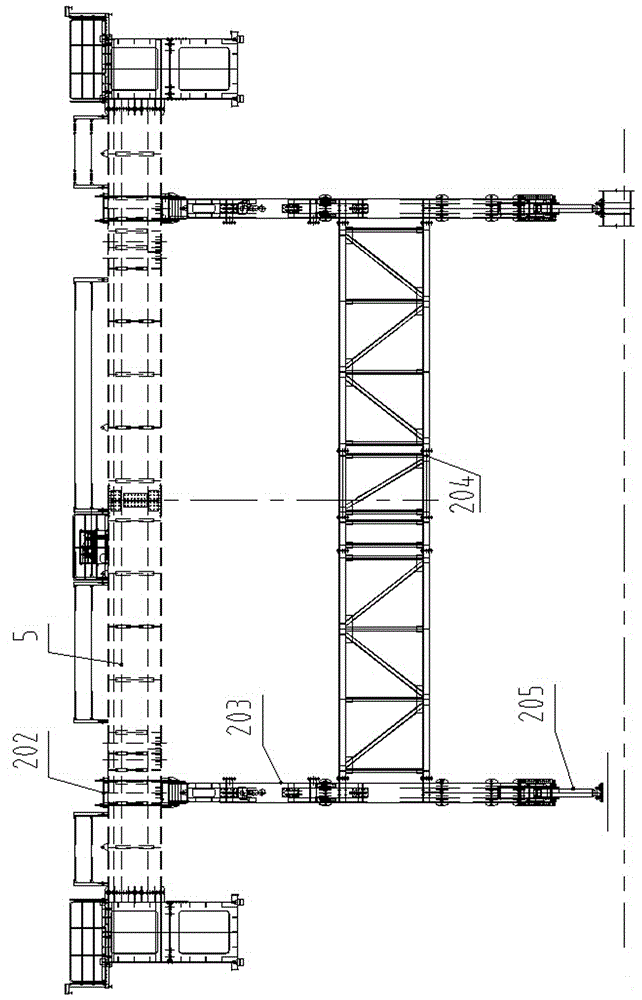

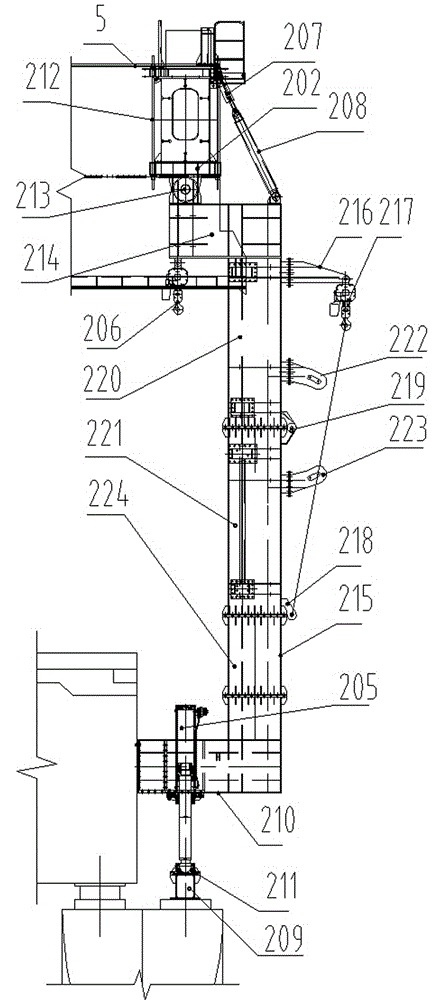

[0101] like Figure 1 to Figure 21 As shown, the new large-tonnage bridge erecting machine includes a main frame structure composed of the main girder 4 of the bridge erecting machine, the front connecting beam 5 of the main girder, and the rear connecting beam 6 of the main girder. It is characterized in that: the main frame structure is sequentially A central support device 1 , a front auxiliary support device 2 and a rear auxiliary support device 3 are provided in connection.

[0102] like Figure 1 to Figure 9 As shown, the middle support device 1 is arranged under the main girder 4 of the bridge erecting machine, and the middle support device 1 includes a front leg 101 and a rear leg 102 positioned behind the front leg 101. The front leg 101 Including the upper crossbeam 103 of the front outrigger, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com