Gypsum board ceiling light hole anti-breakage structure

A technology for gypsum boards and ceiling lights, applied in building construction, covering/lining, construction, etc., can solve problems such as easily damaged gypsum lamp holes, and achieve the effect of increasing fastness and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

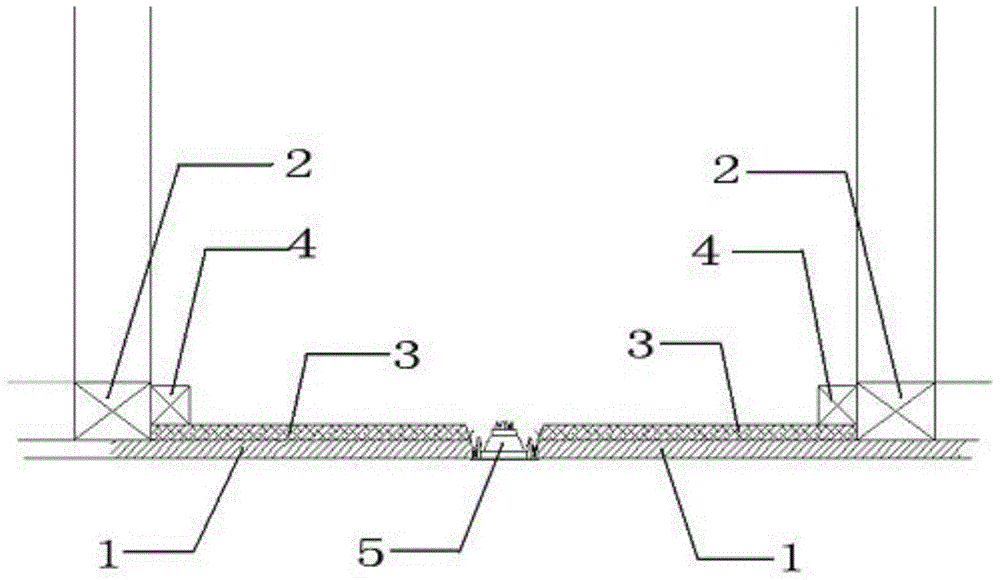

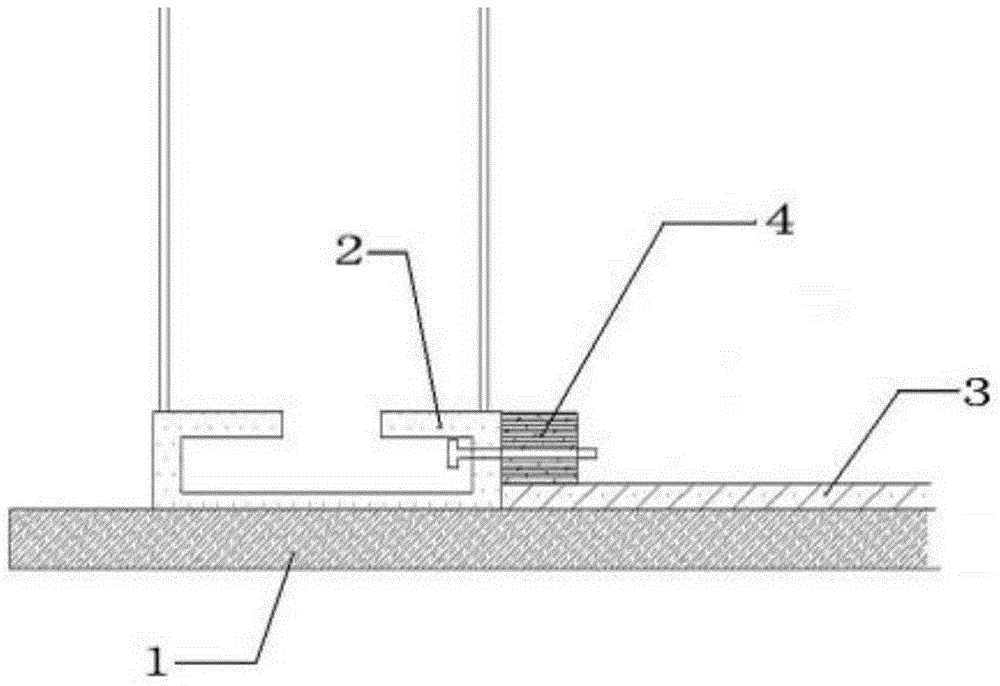

[0012] Embodiment one: as figure 1 As shown, two ceiling joists 2 are fixedly installed on the gypsum board ceiling 1, the ceiling joists 2 are metal frames, and the ceiling joists 2 are suspended on the roof. The two ends of the cement board 3 are fixedly installed with connecting devices 4, such as figure 2 As shown, the connecting device 4 is a solid wood square, and the side of the connecting device 4 is flush with the side of the cement board 3 . The length of the cement board 3 is based on the distance between the two ends of the ceiling joist 2, so that the cement board 3 can just be nested in the space between the ceiling joist 2. At this time, the connecting device 4 and the ceiling joist 2 are tightly attached together. Afterwards, on the outside of the ceiling joist 2, the nuts or screws are penetrated through the ceiling joist 2 and the connecting device 4, so that the two are fixedly connected. In this way, the gypsum board ceiling 1 and the cement board 3 are...

Embodiment 2

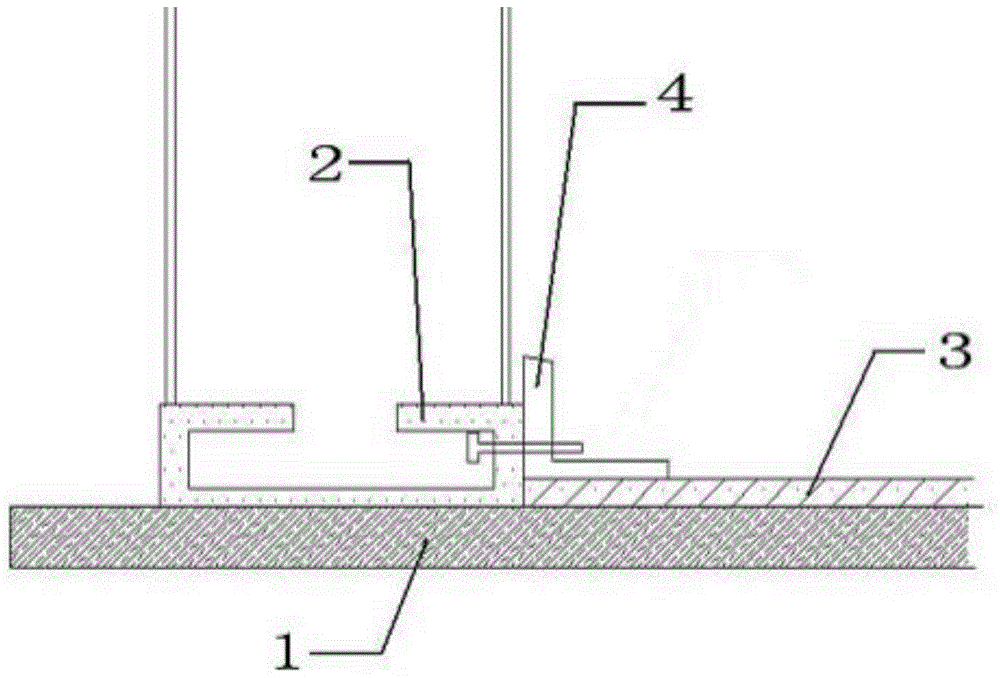

[0013] Embodiment 2: substantially the same as Embodiment 1, the only difference is that the connecting device 4 is an L-shaped channel steel. Such as image 3 As shown, the L-shaped channel steel and the ceiling keel 2 are fixed with nuts.

[0014] The anti-damage structure of the light hole of the gypsum board suspended ceiling of the present invention greatly improves the strength of the gypsum board suspended ceiling 1 due to the addition of the cement board 3, and avoids damage to the light hole accessories when the lamp is replaced or installed. At the same time, the connection of the connecting device 4 It is also very strong and will not damage the overall beauty of the suspended ceiling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com