A plunger for gas well drainage

A technology of plunger and gas well, which is applied in the field of plunger for gas well drainage, can solve the problems of high operating cost and short stable production period of gas well, and achieves the effect of increasing the time of opening well, prolonging the stable production period and avoiding frequent well shut-in.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

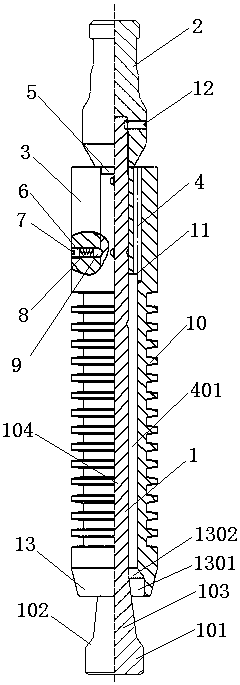

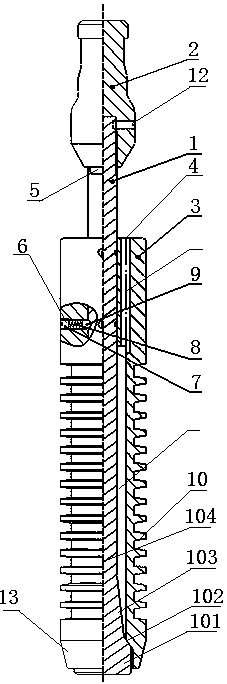

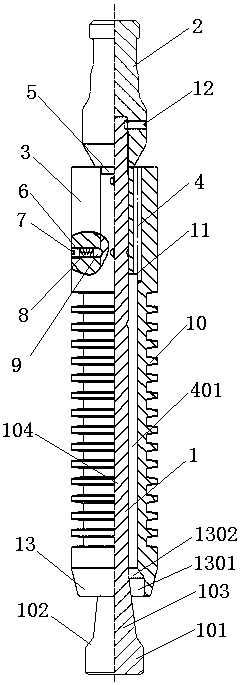

[0021] Such as figure 1 and figure 2 As shown, the present invention provides a plunger for gas well drainage, including a central rod 1, the top of the central rod 1 is fixedly connected with a fishing head 2, and the outer circumference of the central rod 1 is provided with a For the sliding outer cylinder 3, the diameter of the bottom end of the central rod 1 is greater than or equal to the inner diameter of the bottom end of the outer cylinder 3, and the bottom end of the central rod 1 is in sealing contact with the bottom end of the outer cylinder 3, and the inner surface of the outer cylinder 3 and the inner surface of the central rod 1 The outer surface forms a cavity 401 , and a plurality of through holes 4 are opened along the axial direction of the outer cylinder 3 , and the through holes 4 communicate with the cavity 401 .

[0022] Specifically, after the well is opened for production, the gas well drainage plunger is put into the tubing, and the gas well drainage...

Embodiment 2

[0026] On the basis of Embodiment 1, an annular groove 5 is provided on the outer wall of the central rod 1 along its circumference, and a circular hole 6 is provided on the wall of the outer cylinder 3 along its radial direction. A compression screw 7, a spring 8, and a lock block 9 are provided. One end of the lock block 9 is located in the annular groove 5, and the other end is located in the round hole 6. The compression screw 7 is located on the wall of the outer cylinder 3 close to the outer cylinder 3. At one end, the spring 8 is located between the locking block 9 and the compression screw 7, and the spring 8 is connected with the locking block 9 and the compression screw 7 respectively.

[0027] Specifically, one end of the central rod 1 is fixedly connected with the fishing fish head 2 with a boss, and the other end is inserted into the outer cylinder 3, and the locking block 9 and the spring 8 are sequentially loaded into the radial circular hole 6 on the upper end o...

Embodiment 3

[0031] On the basis of Embodiment 1, in order to reduce the weight of the outer cylinder 3 and reduce the gravitational force on the outer cylinder 3 sliding up and down along the central rod 1, a herringbone-shaped circular platform 10 is arranged on the wall of the outer cylinder 3 of the outer cylinder 3 ,Such as figure 1 with figure 2 As shown, the section is jagged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com