Downhole Gas Production String and Gas Production Method

A technology of gas production pipe and velocity pipe string, which is applied in the direction of production fluid, earthwork drilling and production, wellbore/well components, etc. It can solve the problems of incomplete drainage, limited self-excitation function, re-accumulation, etc., and achieves favorable Safe production and production management, reduction of technical costs, and effects of reducing wellhead pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

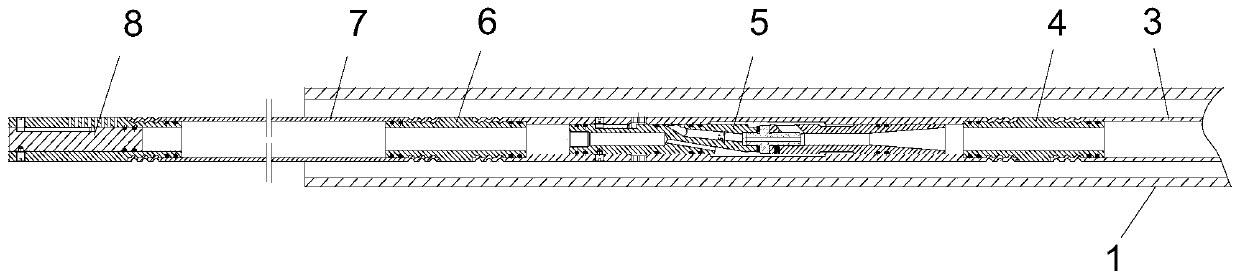

[0020] like figure 1 The downhole gas production string shown in the present invention has a velocity string 3 and a double-channel jet pump 5 connected through a first straight joint 4 . The other end of the double-channel jet pump 5 is connected with a suction pipe 7 through the second straight connector 6, and the suction pipe directly acts on the bottom of the well, which has better water-carrying performance. A screen pipe 8 is also connected to the lower end of the suction pipe 7 . The outer diameters of the velocity column 3, the double-channel jet pump 5 and the suction pipe 7 are consistent. In actual application, an oil pipe 1 is sleeved outside the downhole gas production string.

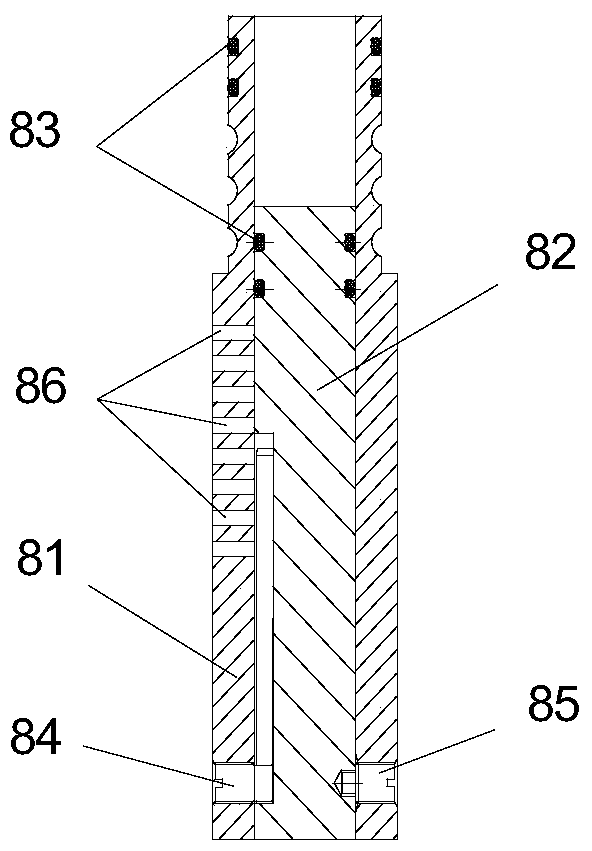

[0021] like figure 2 The screen 8 shown includes a screen outer cylinder 81 with a sealing ring 83 at the joint end, and a downhole fluid inlet 86 is provided on the screen outer cylinder 81 . A movable core 82 that can move axially along the outer cylinder 81 is set inside the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com