Composite oil flooding experimental method of alternately injecting gel and polymer solution after water flooding and polymer flooding

A polymer solution and composite flooding technology, which is applied in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve the problem of low oilfield oil recovery, etc. The effect of oil efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

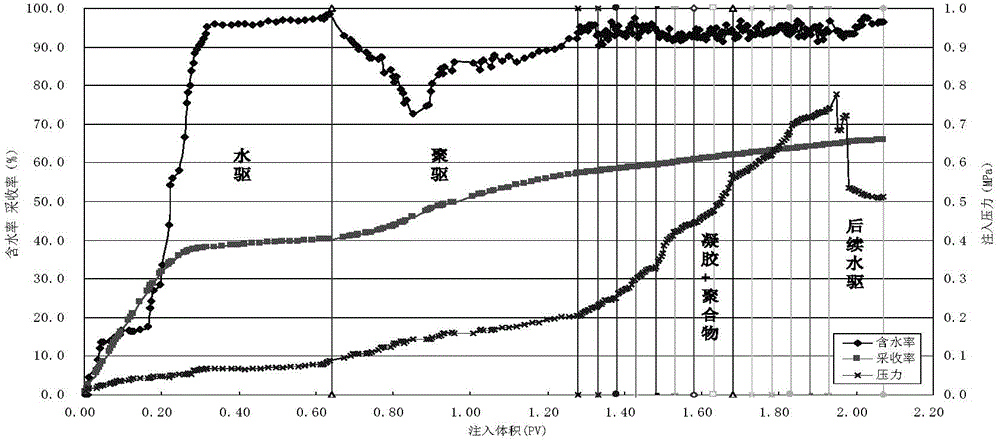

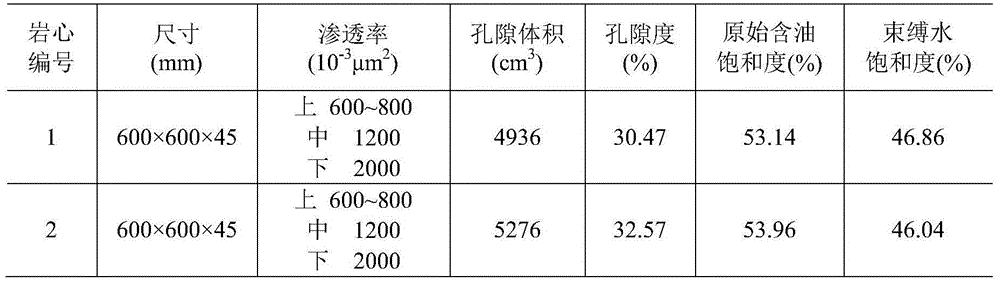

[0032] Using the first large slab core, multiple rounds of alternating injection flooding experiments with small slugs of gel and larger slugs of polymer solution were carried out after water flooding and polymer flooding. The original oil saturation of the first large slab core is 53.14%. According to the experimental procedure, firstly, the water content of the core outlet is water-flooded to 98%, and the water-flooding recovery rate is 40.16%. The yield was 17.02%; then, alternate injection of 0.02PV gel + 0.03PV polymer solution was used for oil displacement, a total of 13 rounds of injection of gel + polymer solution, 0.65PV, followed by water injection until the water cut reached 90% . The recovery of gel + polymer solution alternate injection flooding (including subsequent water flooding) increases by 8.78% on the basis of polymer flooding.

[0033] Such as figure 1 as shown, figure 1 It is the curve diagram of the experimental results of gel+polymer flooding altern...

Embodiment 2

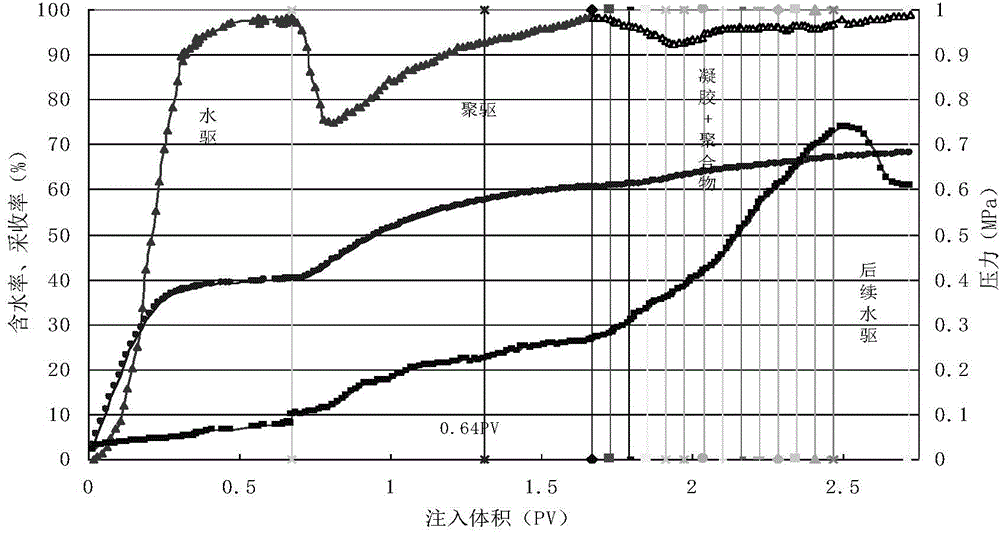

[0035]The second largest slab core was used to conduct polymer flooding after water flooding until the water cut reached 98%, and then multiple rounds of alternating injection of small slugs of gel and larger slugs of polymer solution were used for flooding experiments. The second largest slab core had an original oil saturation of 53.96%. According to the experimental procedure, firstly, the water content at the outlet of the water flooding core reaches 98%, and the water flooding recovery rate is 40.08%; then polymer flooding, when the polymer flooding reaches 0.64PV, the recovery rate at this stage is 17.48%, and the polymer flooding continues until the water cut It reached 98% (0.99PV), and the recovery increased by 2.88% at this time, and the ultimate recovery of polymer flooding increased by 20.36% on the basis of the recovery of water flooding. Next, 0.02PV gel + 0.03PV polymer solution was alternately injected to drive oil. A total of 13 rounds of gel + polymer solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com