Threaded fastener and screwing method thereof

A threaded fastener and thread technology, which is applied in the field of threaded fasteners and their screw connection, can solve the problems of affecting the fastening force of parts assembly, low screw connection efficiency, and easy damage of thread connection, so as to avoid screw tooth collision Damage, the effect of improving the screw connection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

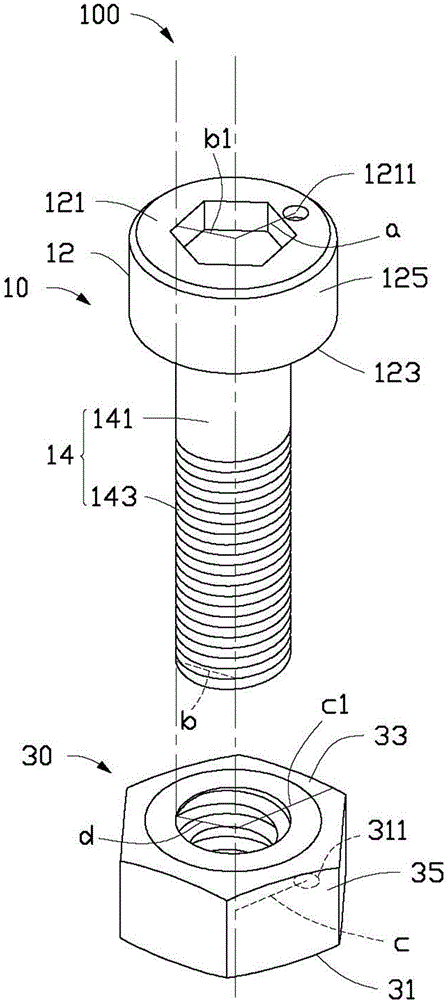

[0018] see figure 1 , the threaded fastener 100 according to the embodiment of the present invention includes a first threaded member 10 and a second threaded member 30 matched with the first threaded member 10 .

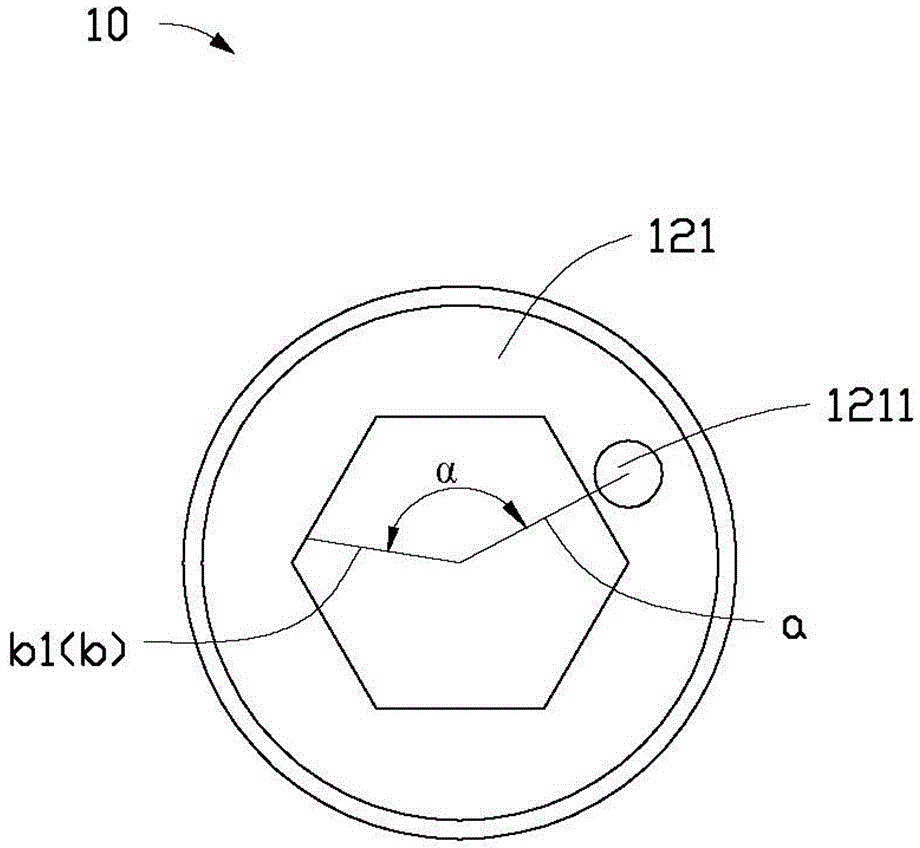

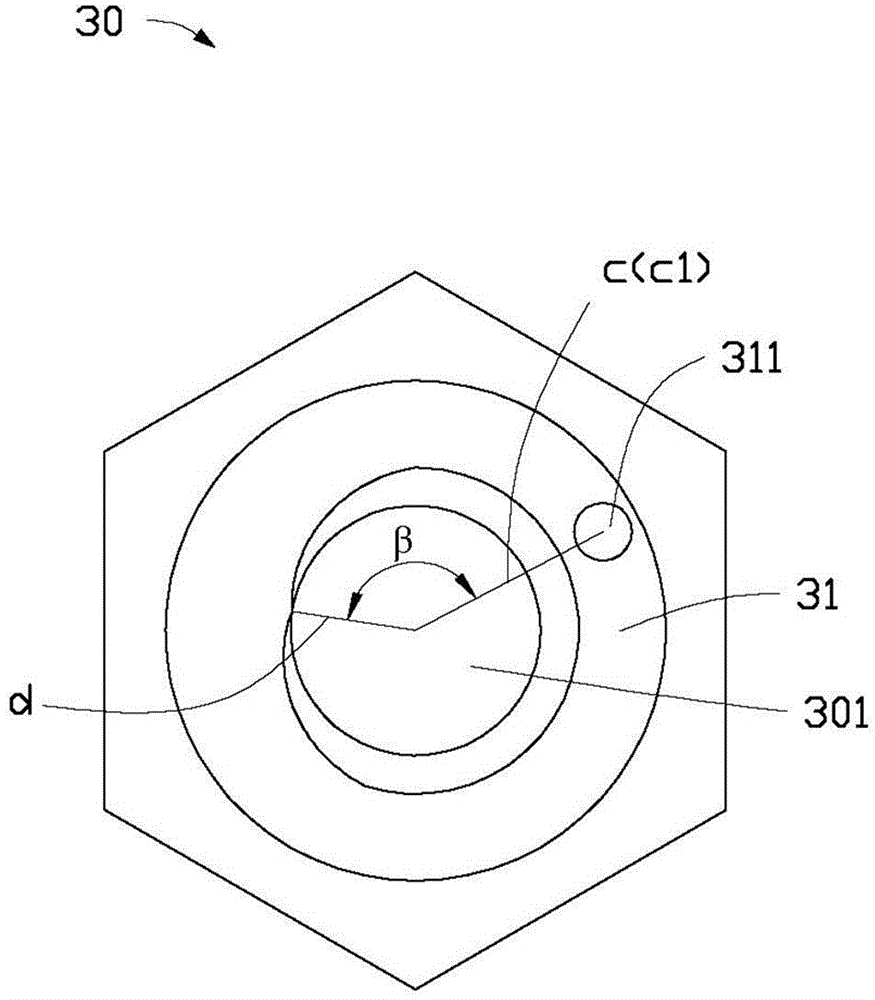

[0019] Please also see figure 2 , in this embodiment, the first threaded member 10 is a hexagon socket head bolt, which includes a head 12 and a screw 14 disposed at one end of the head 12 . The head 12 is roughly cylindrical, and includes opposite first end surfaces 121 and second end surfaces 123 , and a first peripheral wall 125 connected to both the first end surface 121 and the second end surface 123 . A first positioning portion 1211 is formed on the first end surface 121 for positioning the second screw member 30 . In this embodiment, the first positioning portion 1211 is concave. The screw 14 protrudes from the first end surface 121 of the head 12 , and includes a polished rod portion 141 close to the head 12 and a threaded portion 143 adjacent to one en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com