Roller assembly

A roller and assembly technology, which is applied in the field of forklift roller assembly, can solve the problems that the mechanism cannot work normally, the anti-loosening top sheet cannot be self-adjusted, and the roller is easily damaged, so as to prolong the non-destructive working time, good buffering effect, The effect of reducing the damage rate of the roller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

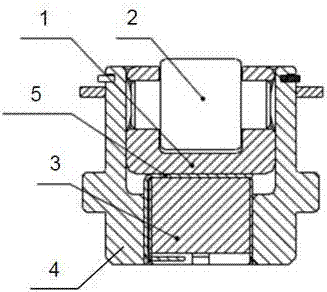

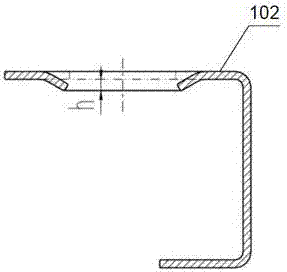

[0014] like figure 1 , figure 2 The present invention shown comprises the mounting base 104 that is provided with the threaded through hole, is provided with the roller seat 101 in the mounting seat 104, and the roller 107 is worn on the roller seat 101 by the shaft on it, and the top wire 103 passes through the mounting seat 104 The threaded through hole of the roller seat 101 is in contact with the bottom surface of the roller seat 101, and an anti-loosening top sheet 102 is provided between the bottom surface of the roller seat 101 and the jacking wire 103. The middle part of the top surface of the anti-loosening top sheet 102 is provided with a downwardly recessed upper large Lower the small round platform, the middle part of the round platform is provided with a through hole corresponding to the shape of the round platform, the height from the bottom edge of the through hole to the lower end of the top surface of the anti-loosening top sheet 102 is h, and the height h is...

Embodiment 2

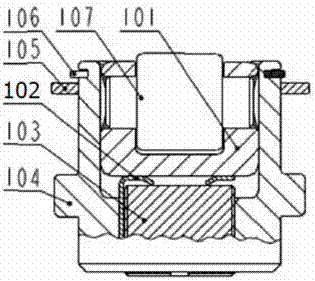

[0016] like Figure 4 As shown, the roller assembly in the present embodiment is compared with the roller assembly in Embodiment 1, and its difference is: the top end surface of the top wire 103 is provided with the through hole of the round platform of the anti-loosening top sheet 102. Cooperating boss 108, the height of this boss 108 is correspondingly set with the height h of the bottom edge of the middle part through hole of the top surface round table of the anti-loose top sheet 102 to the height h of the top surface lower end of the anti-loose top sheet 102, when the anti-loose top sheet 102 When the elastic force of the round platform on the top surface weakens or fails, the boss 108 can directly contact the bottom surface of the roller seat 101, which plays a role of limiting and buffering the top wire 103, and can better prevent the roller 107 from being damaged by an instant impact. damage, to ensure the normal operation of the entire mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com