Force-value-adjustable small-included-angle ratchet wheel positioning device with V-shaped positioning grooves

A positioning device and positioning groove technology, applied in the direction of brake type, mechanical equipment, etc., can solve the problems of inability to adjust the rotational operating force value of the driving ratchet, positioning interference, etc., and achieve the effect of saving mechanism space and alleviating positioning interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in combination with specific embodiments.

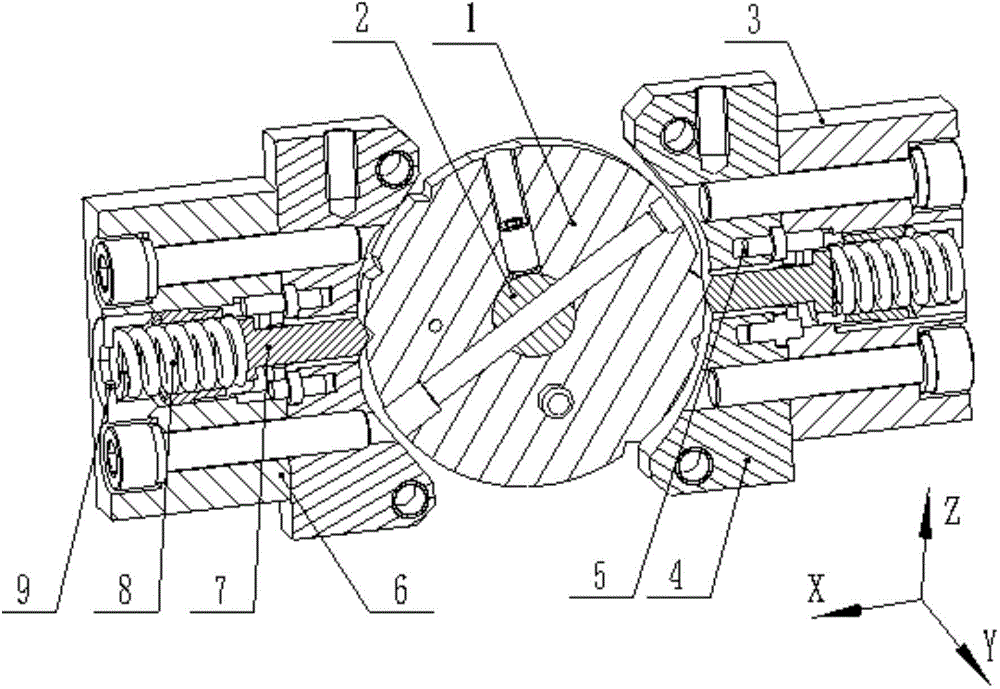

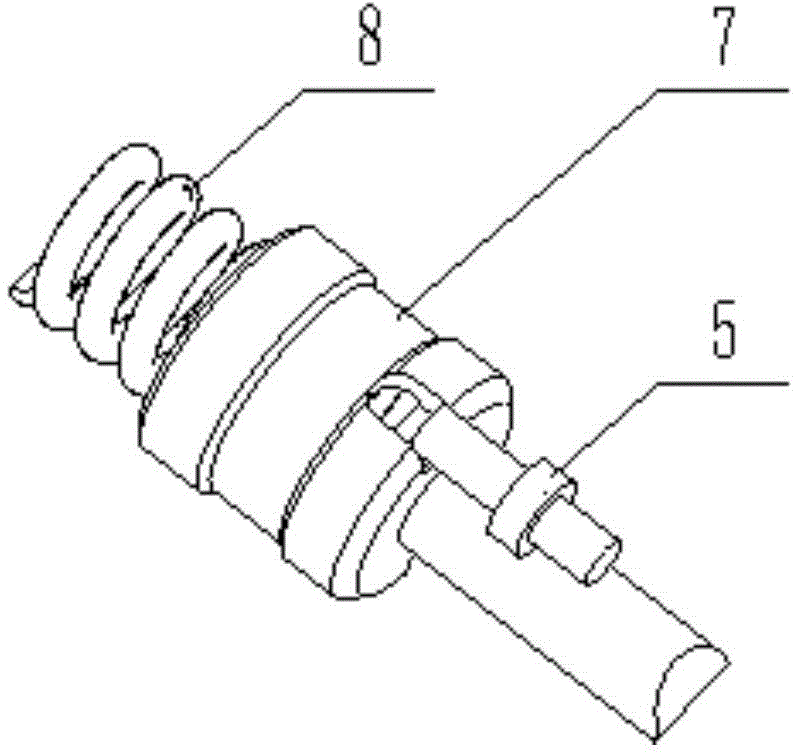

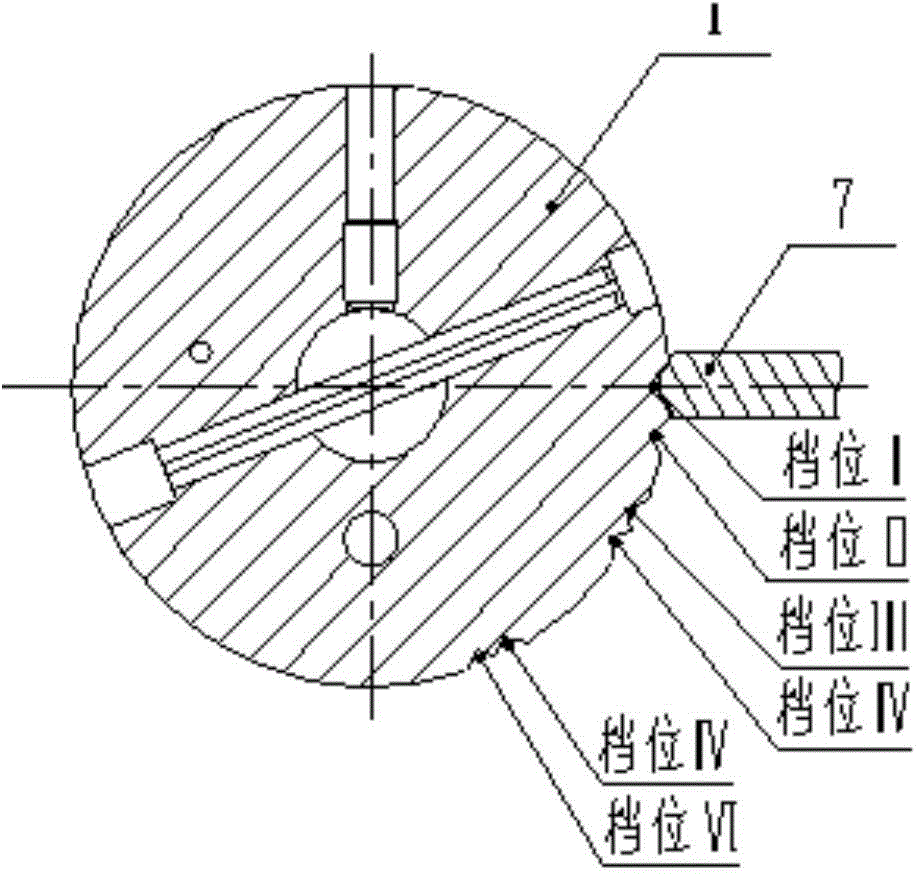

[0016] The structure of a ratchet small angle positioning device with adjustable force value and V-shaped positioning groove provided by the present invention is as follows: figure 1 As shown, it includes a ratchet 1 and two positioning components 3 installed on the main shaft 2. The ratchet 1 can rotate around the Y axis shown in the figure. There are several V-shaped positioning grooves alternately distributed on both sides of the circumference of the ratchet 1. Two The positioning assembly 3 is respectively installed on the brackets 4 on both sides of the ratchet 1, such as figure 2 As shown, the bracket 4 is equipped with a detent pin 5 to limit the rotation of the positioning pin 7 around the X axis. Contact with the circumferential surface of the ratchet 1 under the action, by changing the screwing depth of the positioning nut 9 and the positioning block 6, adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com