NFC antenna integrated on ferrite and preparation method thereof

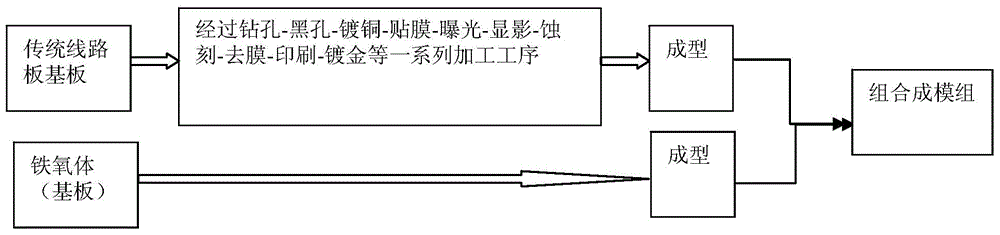

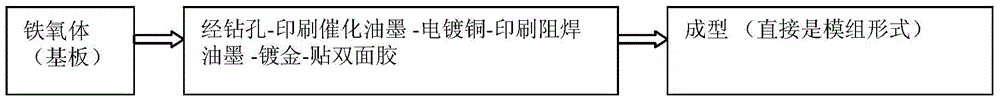

A technology of ferrite and ferrite layer, applied in the direction of antenna support/mounting device, radiation element structure, etc., can solve the problems of low production efficiency, long processing cycle, thick thickness, etc., and achieve high production efficiency and high product quality. Thin, save the effect of lamination process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

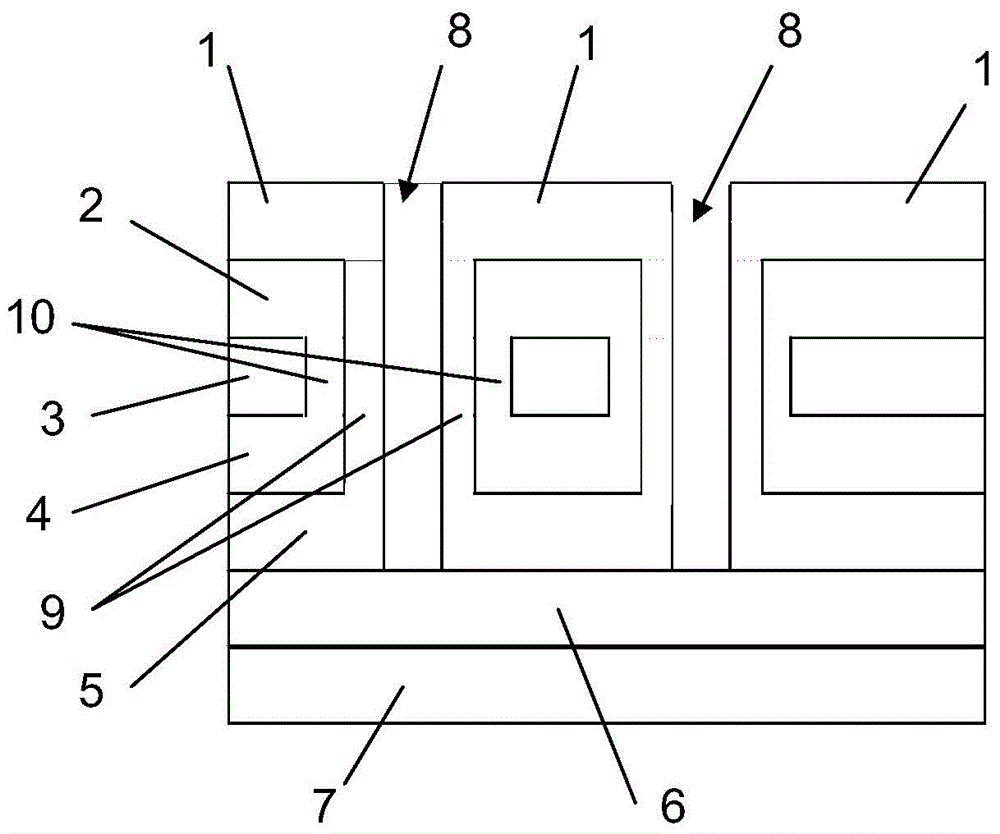

[0025] The NFC antenna integrated on the ferrite of the present invention is as figure 1 As shown, it includes the first electroplated copper layer 1, the first catalytic ink layer 2, the ferrite layer 3, the second catalytic ink layer 4, the second electroplated copper layer 5, the solder resist ink layer 6, Double-sided adhesive layer 7, and several longitudinal holes 8 are also provided on the antenna. The upper end of the longitudinal hole 8 is opened on the upper surface of the first electroplated copper layer 1, and the lower end is on the upper surface of the solder resist ink layer 6, and the two sides of the longitudinal hole 8 are from the outside. The third electroplated copper layer 9 and the third catalytic ink layer 10 are sequentially included in the inner lateral direction, and the third electroplated copper layer 9 is connected with the first and second electroplated copper layers 1 and 5, and the third electroplated copper layer 10 is connected with the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com