Combustion system of a boiler with front and rear walls facing each other

A technology of counter-combustion and combustion system, which is applied to the combustion of block fuel and powder fuel, the combustion of block fuel and gaseous fuel, the combustion of liquid fuel and powder fuel, etc., and can solve the problem of overtemperature and main steam temperature Difficult to control, furnace water wall coking, water wall coking and other problems, to achieve the effect of suppressing the rise of the flue gas temperature and the desuperheating water volume of the superheater, reducing the deviation of the oxygen amount, and increasing the stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

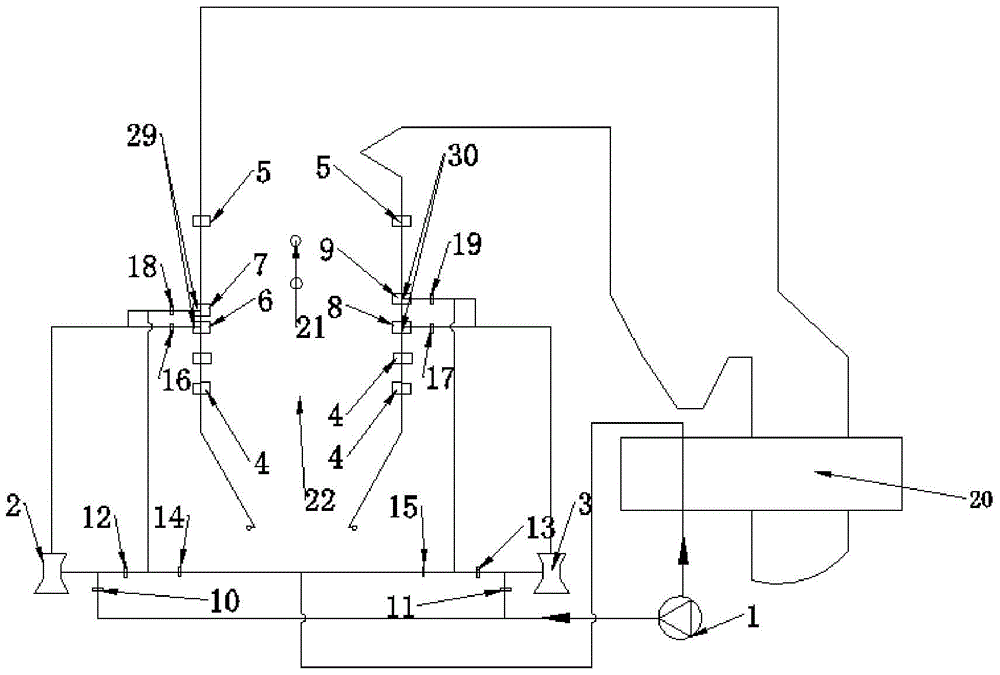

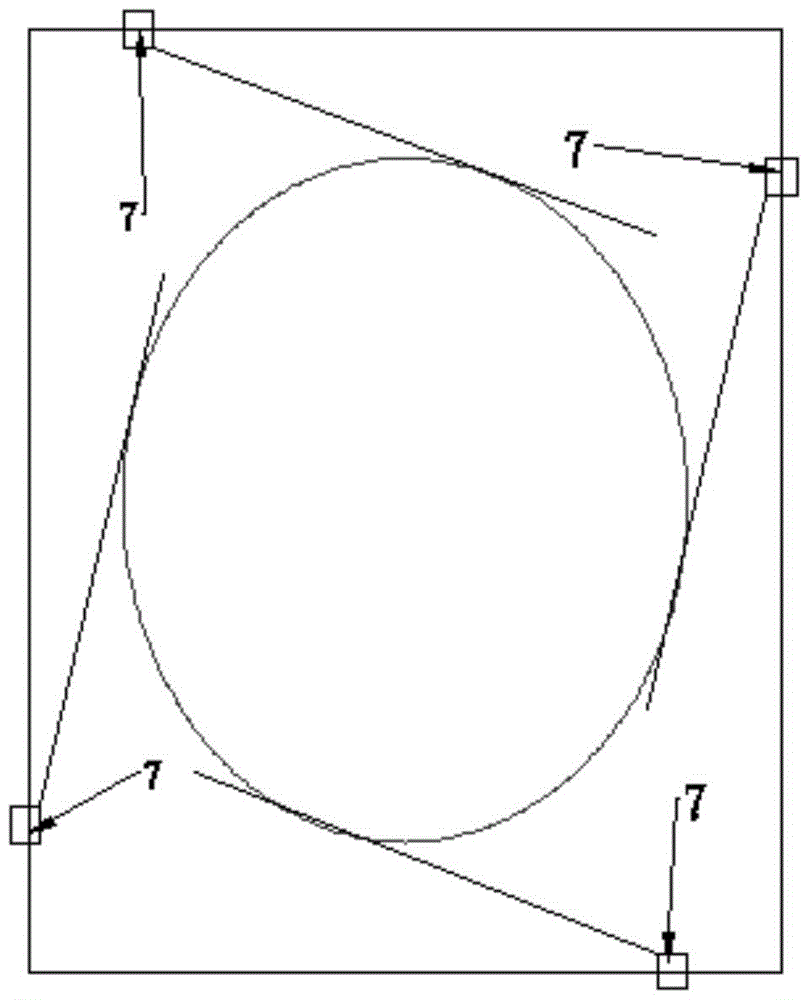

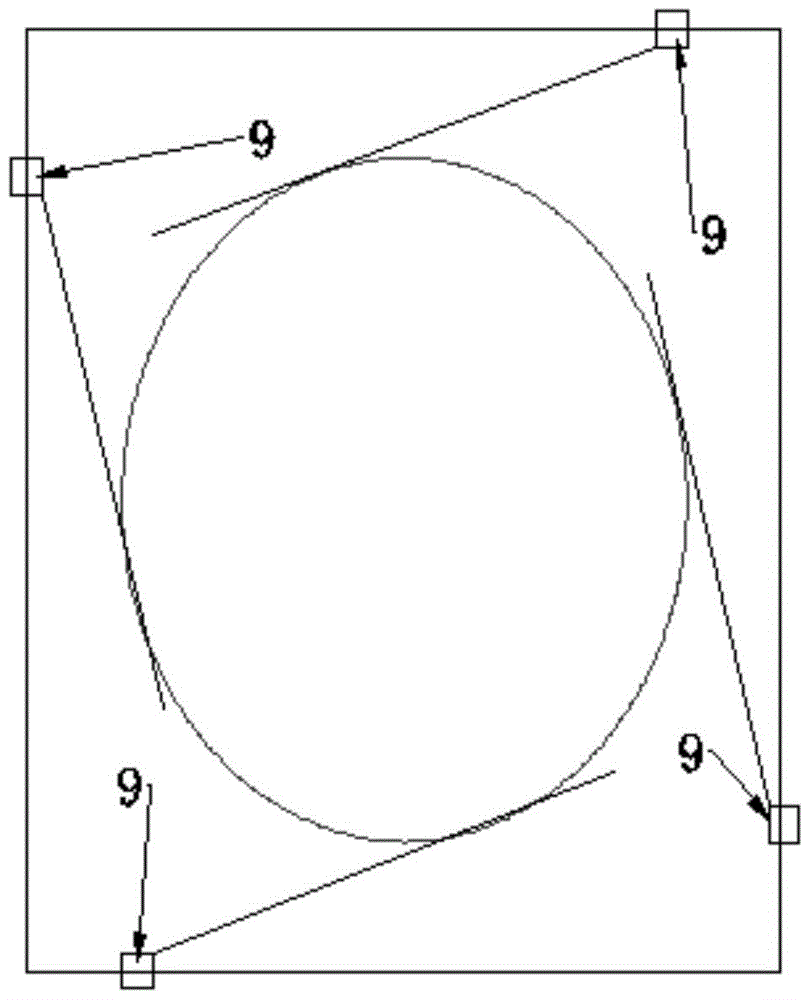

[0029] The present invention is described in further detail below in conjunction with accompanying drawing:

[0030] refer tofigure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , the combustion system of the front and rear walls facing the combustion boiler of the present invention includes a primary fan 1, a secondary fan, an air preheater 20, a first coal mill 2, a second coal mill 3, a furnace 22, several first straight Flow spout 7, some second direct-flow spouts 9, some first swirl burners 6, some second swirl burners 8, some third swirl burners 4 and some burn-off air spouts 5; the primary fan 1 The outlet is divided into two roads, one of which is connected with the entrance of the first coal mill 2 and the entrance of the second coal mill 3 respectively, and the other road passes through the air preheater 20 and the entrance of the first coal mill 2 and the entrance of the second coal mill 2. The inlet of the second coal mill 3, the inlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com