Frequency adjusting and control method for variable-frequency enhanced vapor injection heat-pump water heater

A heat pump water heater and frequency adjustment technology, which is applied to fluid heaters, lighting and heating equipment, etc., can solve the problems of decreased energy efficiency ratio, deviation from the optimal energy efficiency ratio frequency point, and failure to give full play to the energy-saving advantages of frequency conversion technology. energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

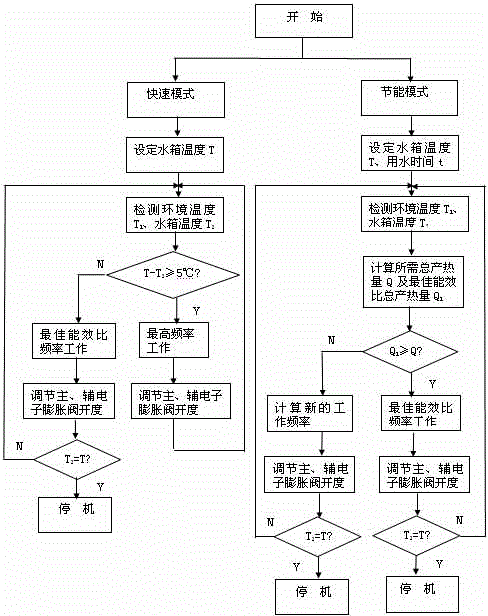

[0014] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

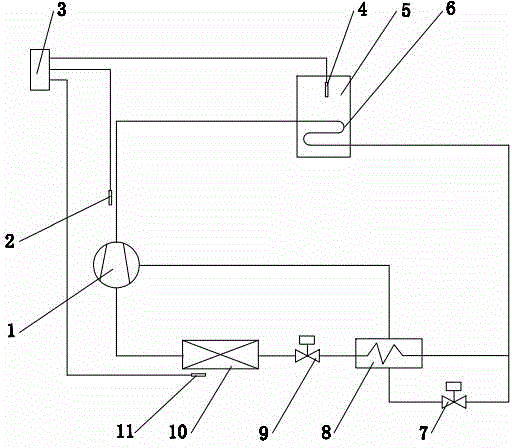

[0015] Air source heat pump water heater includes compressor 1, exhaust temperature sensor 2, controller 3, water tank temperature sensor 4, water storage tank 5, condenser 6, auxiliary electronic expansion valve 7, economizer 8, main electronic expansion valve 9, evaporator 10 and outdoor temperature sensor 11. In this embodiment, the compressor 1 is a variable frequency compressor, and the compressor 1 can also use a variable capacity compressor or a DC speed regulating compressor according to the actual situation; the variable frequency air injection enthalpy heat pump water heater can use water or geothermal heat as the heat source .

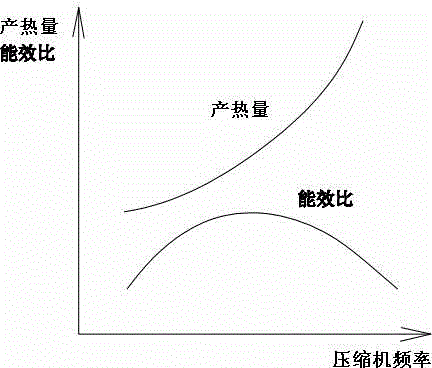

[0016] Energy efficiency rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com