Buckling piece type radiating assembly

An assembly and clip technology, applied in the field of clip-type heat dissipation assembly, can solve the problem of reducing the overall conduction and heat dissipation area of the chip body 11, failing to give full play to heat conduction and heat dissipation, and reducing the overall heat dissipation effect of the heat dissipation assembly 1, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples. Before the present invention is described in detail, it should be noted that in the following description, similar components are denoted by the same numerals.

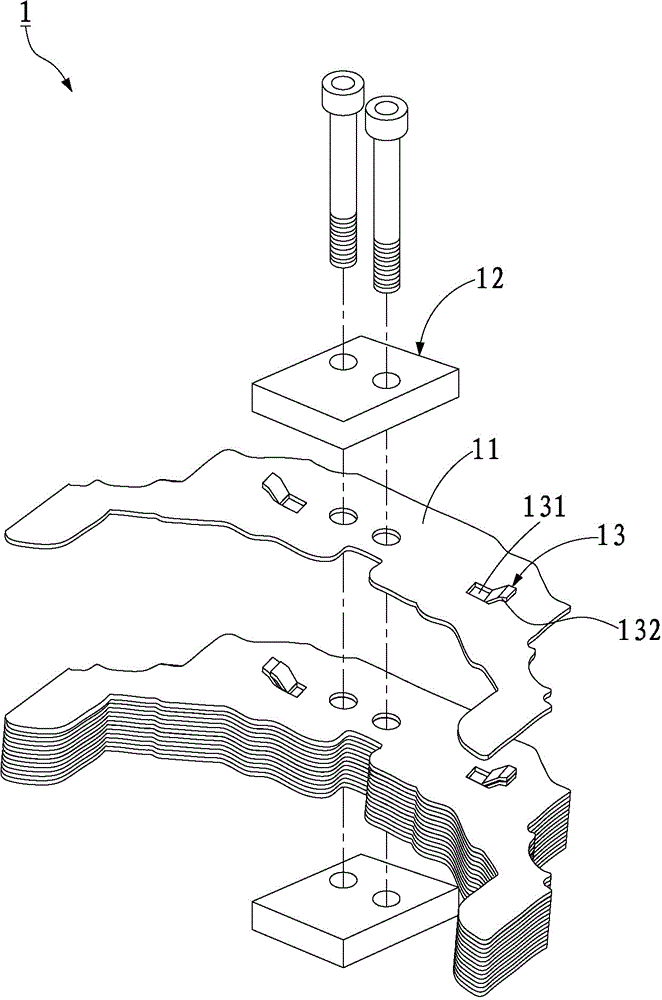

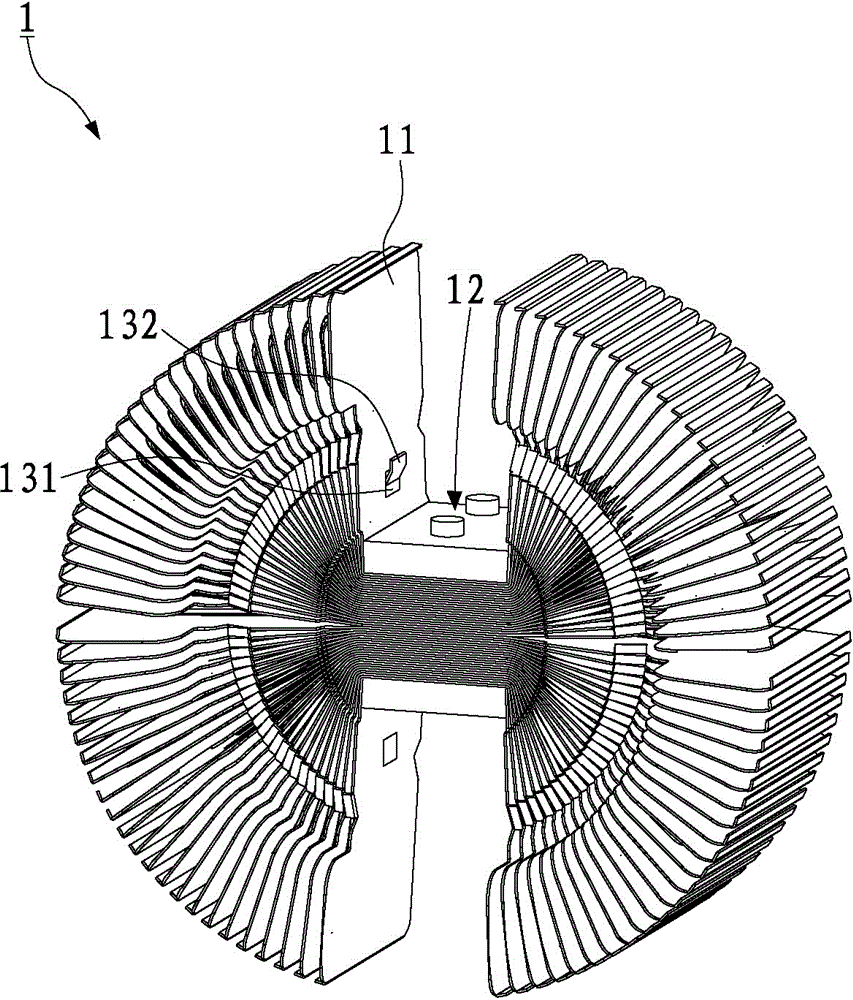

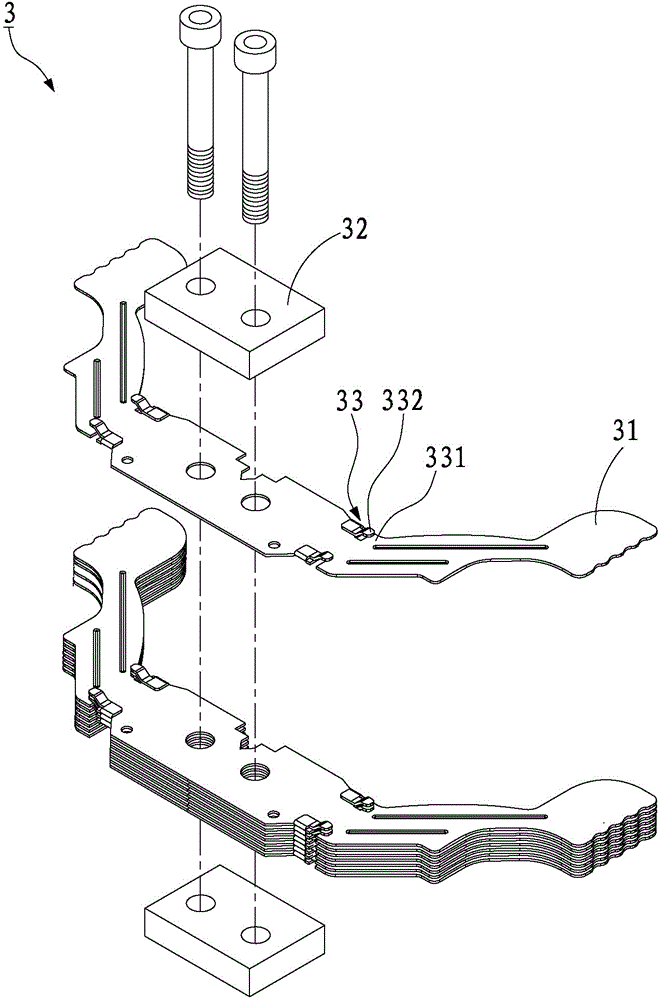

[0028] refer to image 3 , Figure 4 , the first preferred embodiment of the present invention, the buckle-type heat dissipation assembly 3 includes a plurality of pieces 31, and a fixer 32 that connects and fixes the pieces 31 in series; wherein, on the periphery of the pieces 31 A connection portion 33 is provided, and the connection portion 33 has a joint block 332 extending outward from the periphery of the sheet body 31, and a fixed area 331 formed on the sheet body 31, and the aforementioned joint block 332 and the fixed area The position of 331 is no longer on the same plane, so that when the sheets 31 are stacked with each other, the joint bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com