electric motor

A technology for a motor and a main body, applied in the field of motors, can solve the problems of axial vibration and noise of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

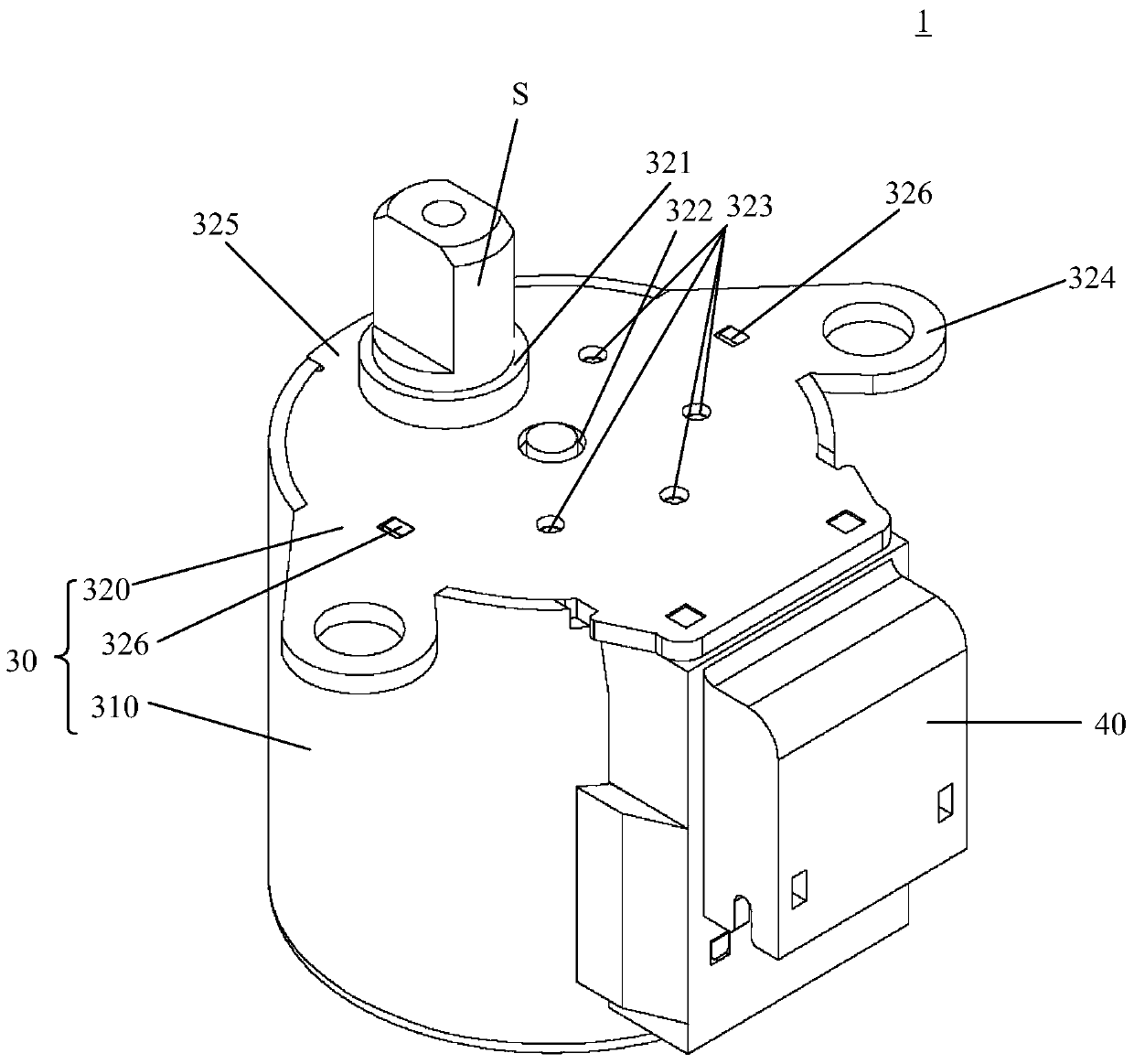

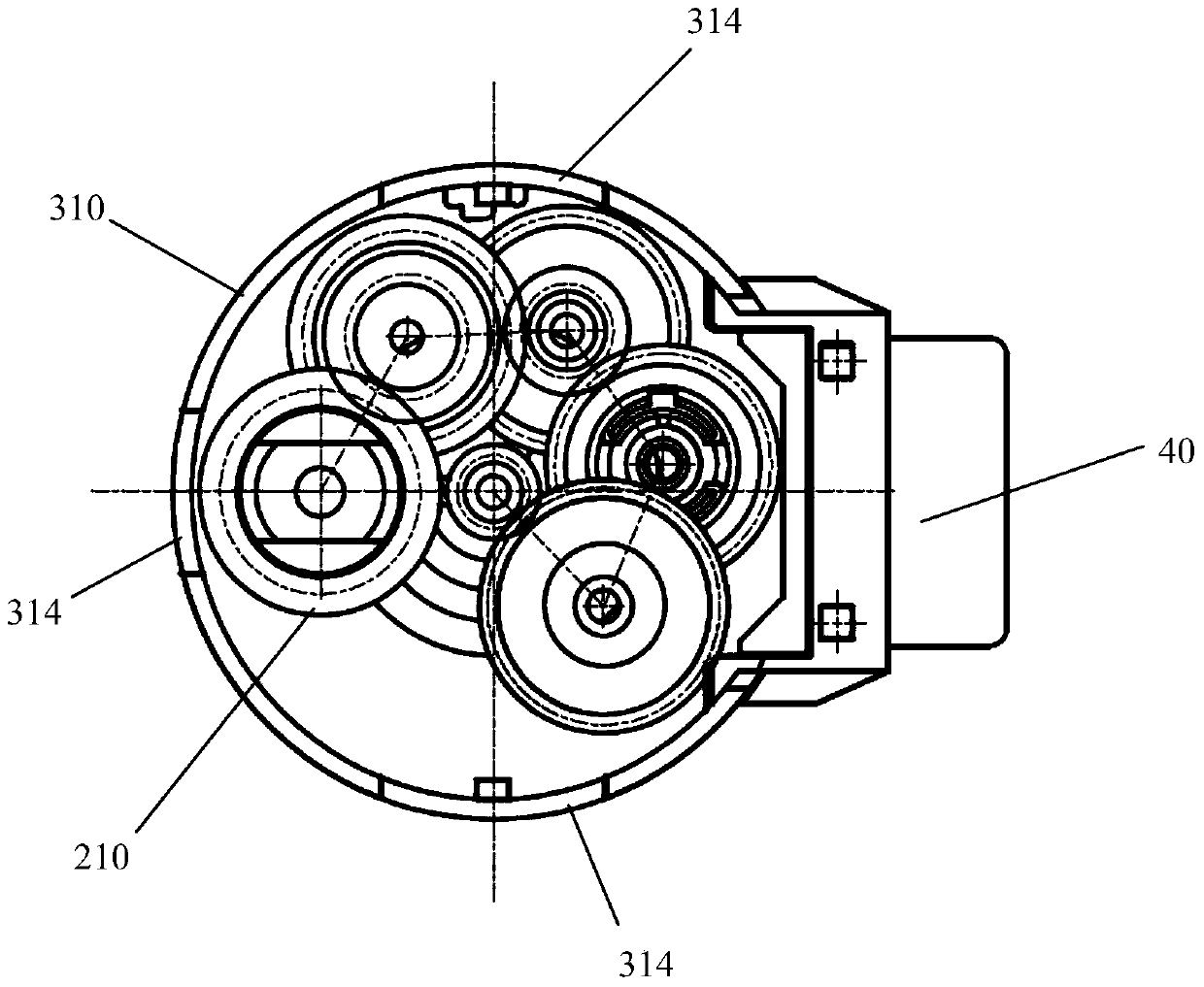

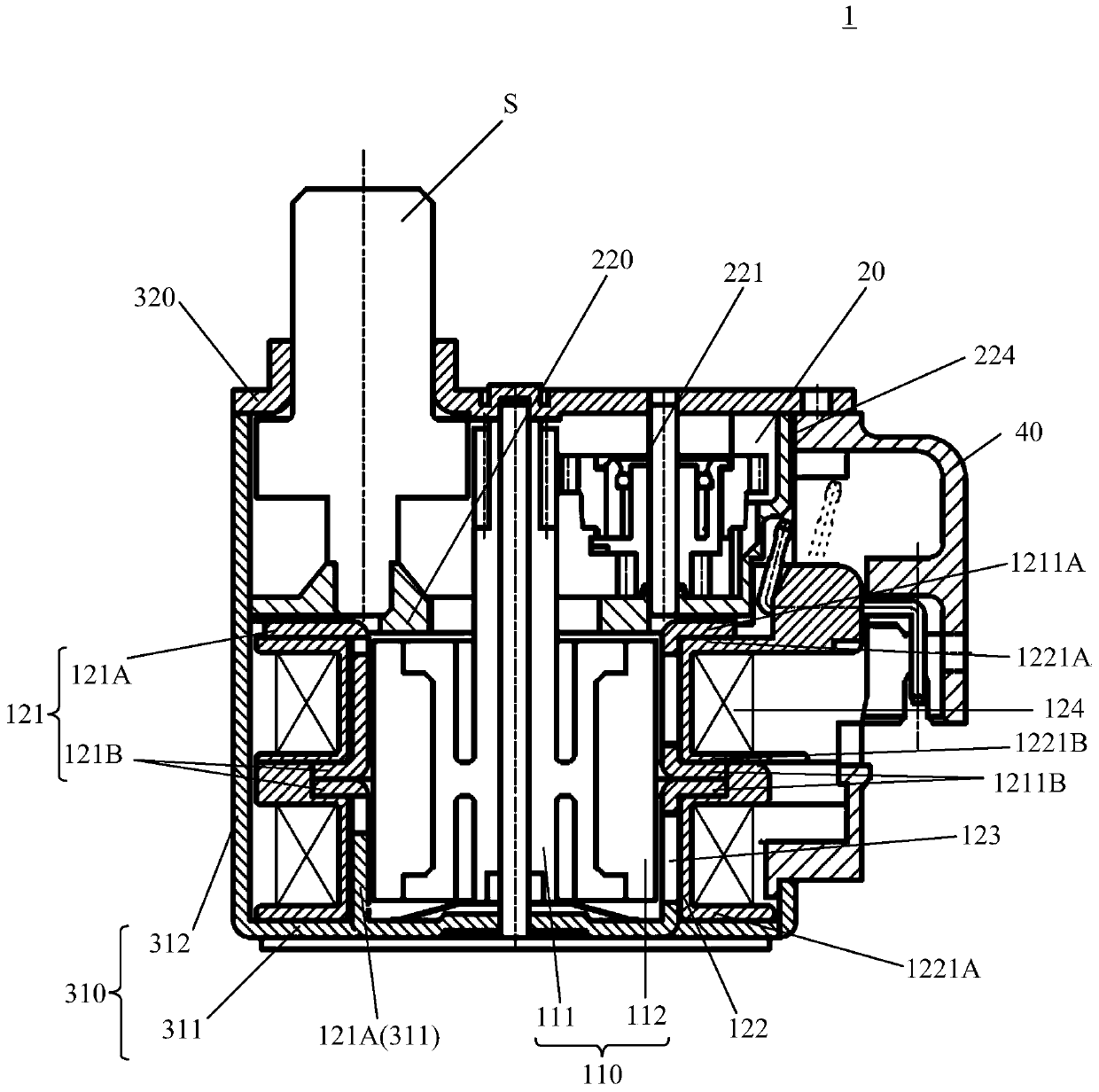

[0045] Hereinafter, a motor according to an embodiment of the present invention will be described in detail with reference to the drawings.

[0046] Also, in the following descriptions, the side where the output shaft of the motor is located (for example, figure 1 , Figure 2B , image 3 The upper side in ) is called "output side", and the side opposite to the above output side is called "anti-output side". In addition, in the following description, "the state before assembly" refers to the state when the components such as the motor body part and the reduction gear part are arranged in the motor case, but the end plate is not fixed to the upper end of the motor case. The "state" refers to a state in which components such as the motor main body and the reduction gear are arranged in the motor case, and the end plate is fixed to the upper end of the motor case.

[0047] (Schematic structure of the motor)

[0048] figure 1 It is a perspective view which shows the whole stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com