Vibration motor

A vibration motor and drive mechanism technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of vibration motor damage, abnormal output shaft angle, and shortened service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

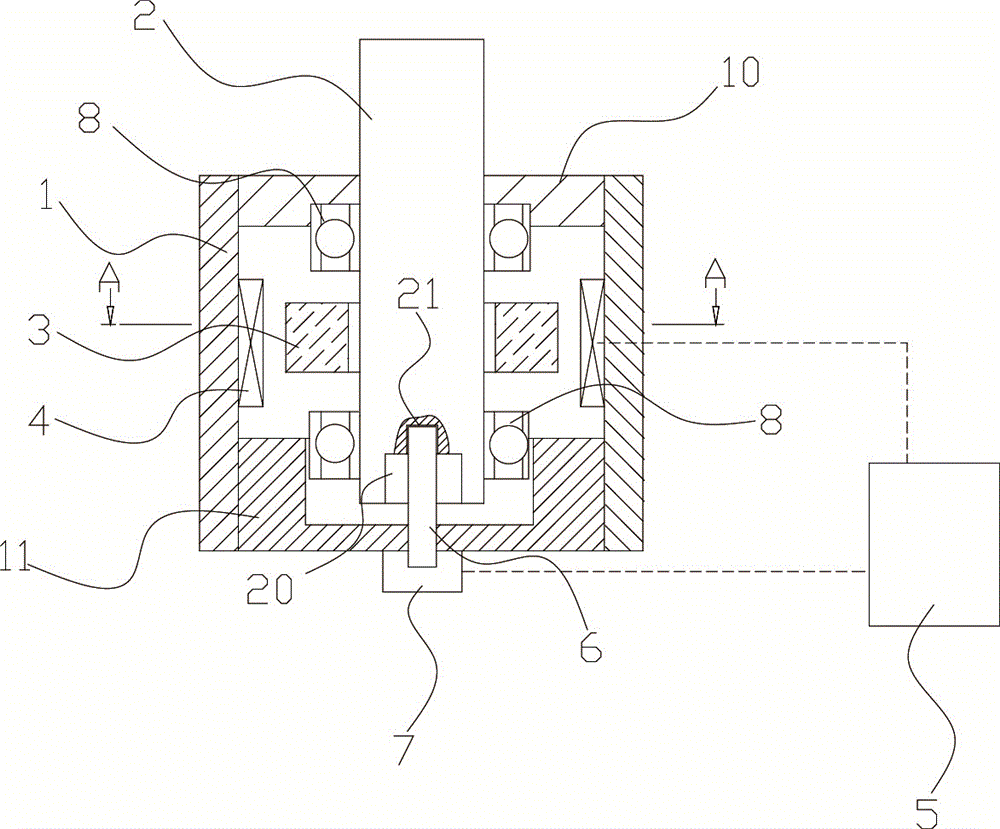

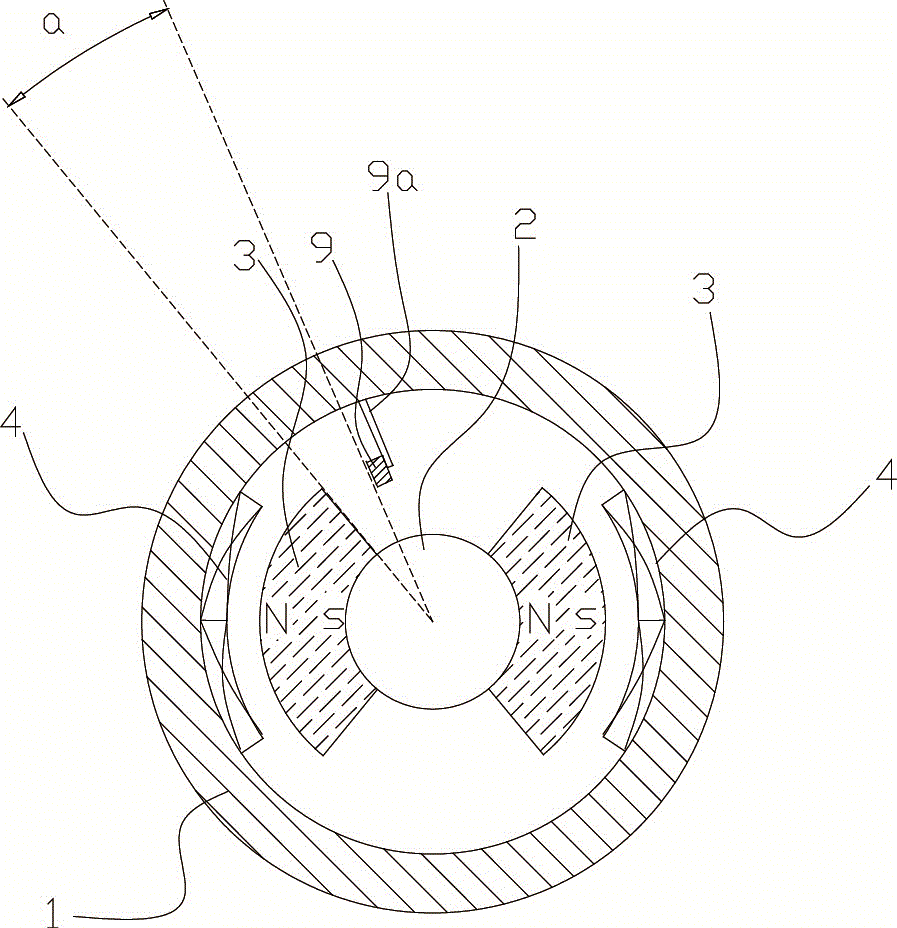

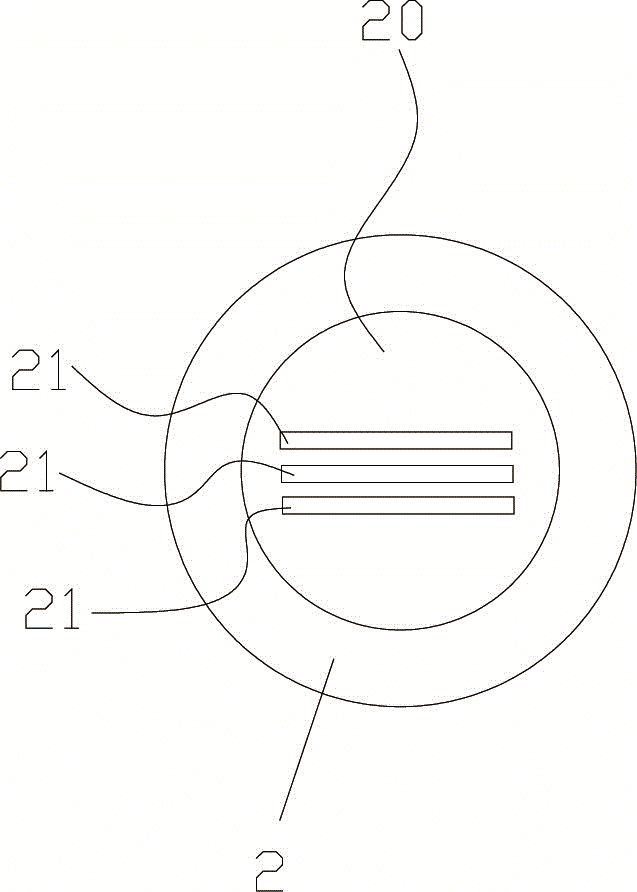

[0013] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 2 , a vibration motor, including a housing 1, the housing 1 includes an upper end cover 10 and a lower end cover 11, an output shaft 2 is rotated in the housing 1, and in the upper end cover 10 and the lower end cover 11 A bearing 8 for supporting the output shaft 2 is provided, and two oppositely placed coils 4 are provided on the side wall of the housing 1, and AC power is passed through the coils 4 so that an alternating current is formed between the coils. The magnetic field also includes a gear switch 5 for controlling the frequency of the AC power supply, and an armature component 3 corresponding to the coil 4 is fixedly arranged on the output shaft 2 . There is a gap between the armature component 3 and the coil 4, so that the output shaft 2 can reciprocate at a specific angle within the range of the gap, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com