Cotton yarn knitting machine

A knitting machine, cotton yarn technology, applied in knitting, weft knitting, flat knitting machines with separate action needles, etc., can solve the problems of unqualified clothing quality and increased rejection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

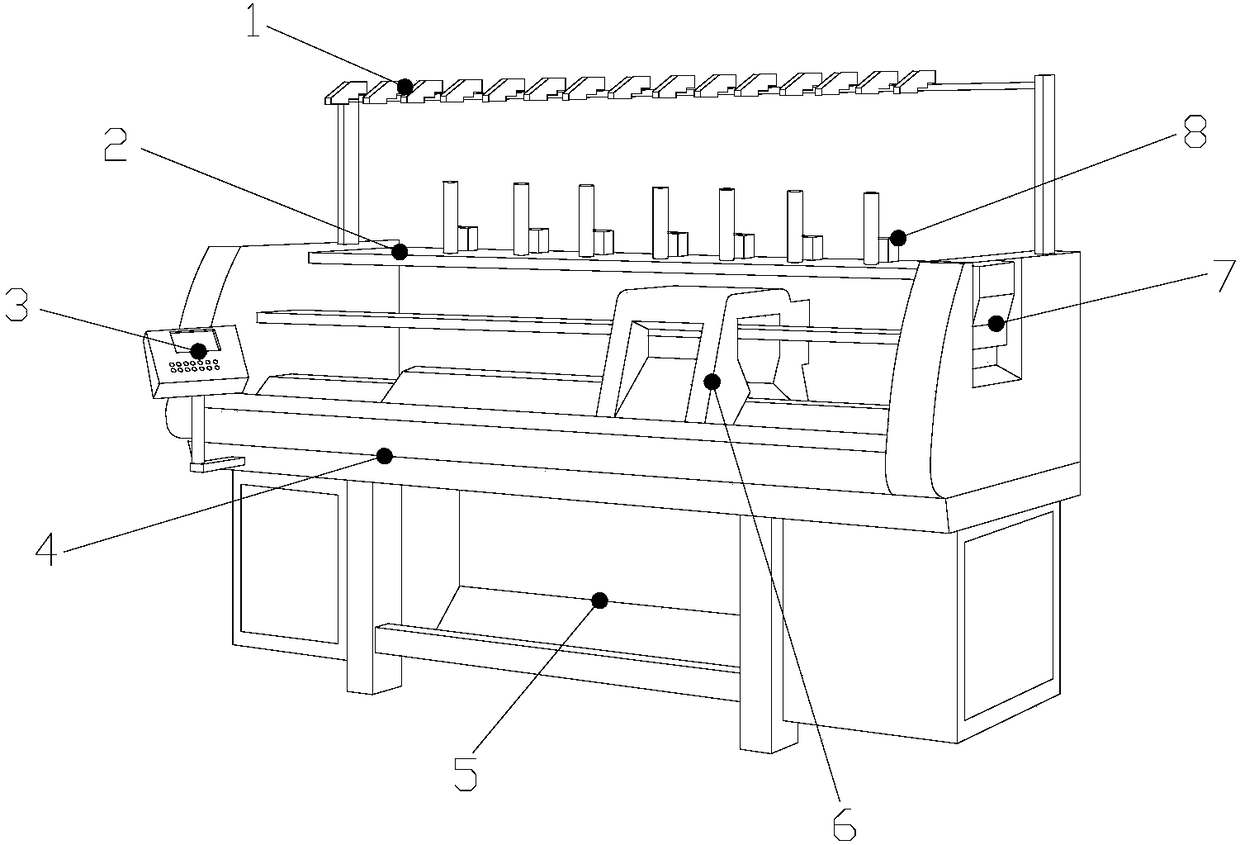

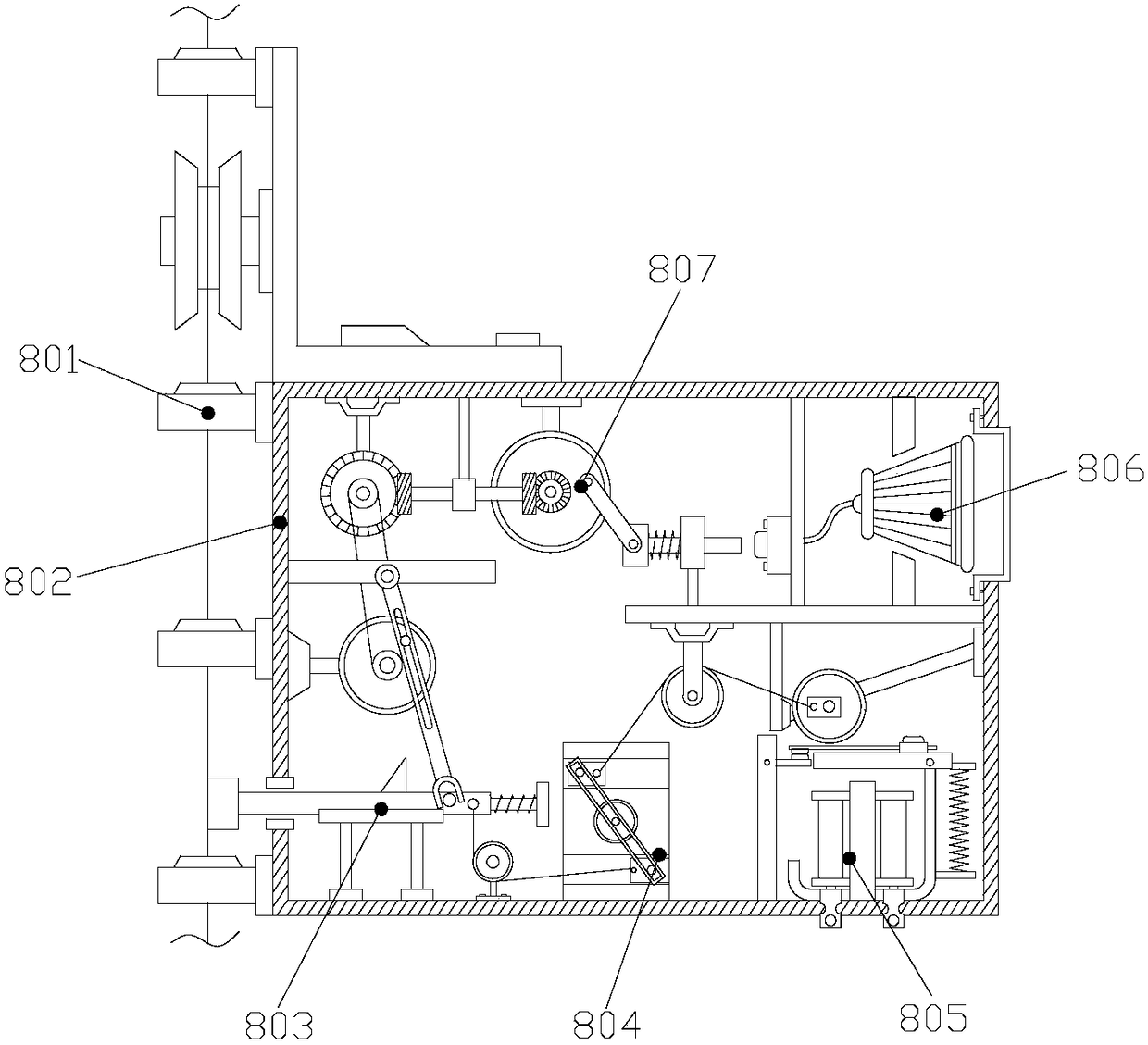

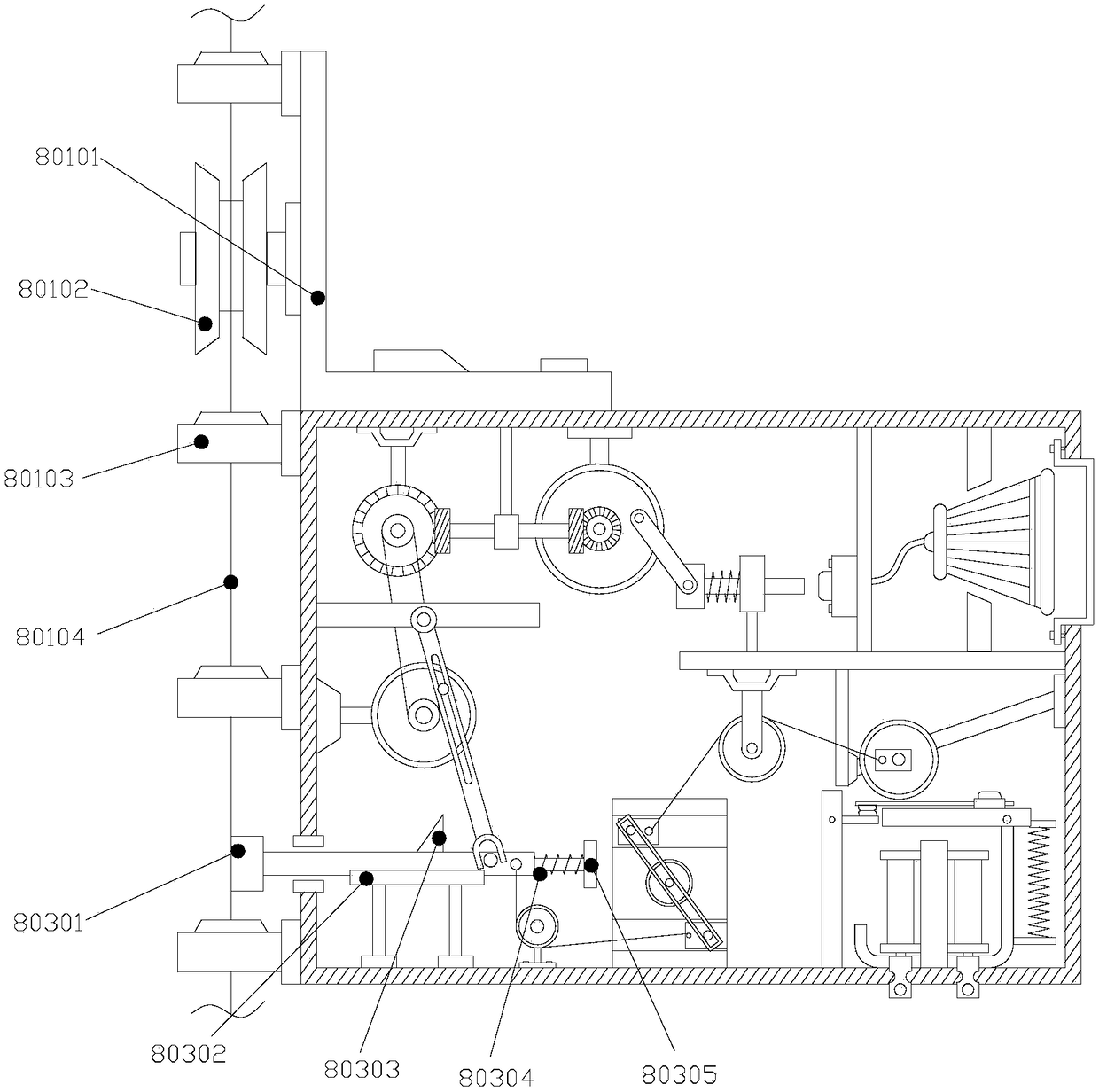

[0021] like Figure 1-Figure 5 As shown, the present invention provides a cotton yarn knitting machine, the structure of which includes a cotton yarn lead frame 1, a yarn roll fixing table 2, a plc controller 3, a knitting processing table 4, an equipment support frame 5, a knitting machine head 6, and a cotton yarn holder 7. 8, the disconnection alarm device 8, the knitting processing table 4 is horizontally installed in the middle of the front of the equipment support frame 5, the knitting machine head 6 is mechanically connected to the top of the knitting processing table 4, and the plc controller 3 is bolted to the equipment support frame. 5. The leftmost end is electrically connected with the knitting machine head 6. The cotton yarn holder 7 is provided with two bolts to be fixed on the tops of the left and right sides of the equipment support frame 5, and the yarn roll fixing table 2 is welded to the top of the equipment support frame 5. Parallel to the knitting processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com