Drive device and the corresponding rotary furnace

A technology of driving device and rotary furnace, applied in transmission device, gear transmission device, rotary drum furnace, etc., can solve the problems of expensive steel and difficult ring gear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

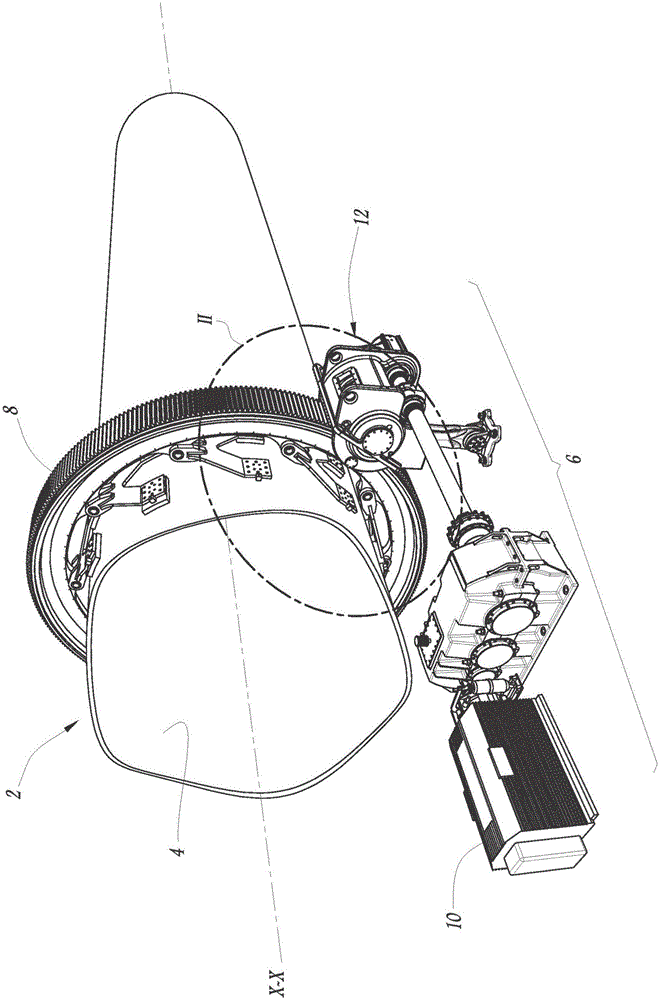

[0019] figure 1 A rotary kiln according to the invention is shown in (generally designated with reference number 2 ).

[0020] The rotary kiln 2 consists of a combustion chamber 4 and a drive 6 .

[0021] The combustion chamber 4 is generally cylindrical and mounted for example to be rotatable about an axis of rotation X-X in a support not shown.

[0022] The drive means 6 are able to drive the combustion chamber 4 in order to rotate the combustion chamber 4 about the axis of rotation X-X.

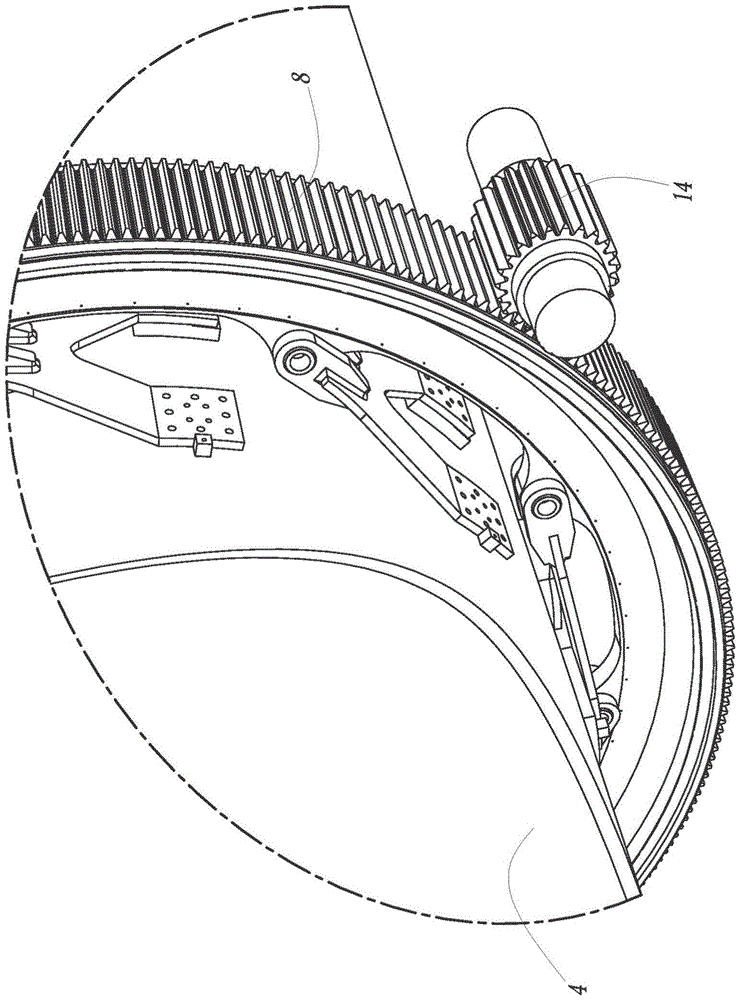

[0023] The drive device 6 consists of a drive ring gear 8 . A ring gear 8 surrounds the combustion chamber 4 and is attached for rotation about the combustion chamber 4 .

[0024] The driving device 6 also includes a driving motor 10 and a gear reducer 12, the gear reducer 12 is provided with a driving pinion 14, and the driving pinion 14 is an output pinion of the gear reducer. The drive pinion 14 meshes with the drive ring gear 8 . The gear reducer 12 is driven by the drive motor 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com