Solder paste supply device

A technology for solder paste and connecting parts, which is applied in tin feeding devices, welding equipment, printed circuits assembled with electric components, etc. It can solve the problems of solder paste waste, separation of solder particles and liquid flux, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

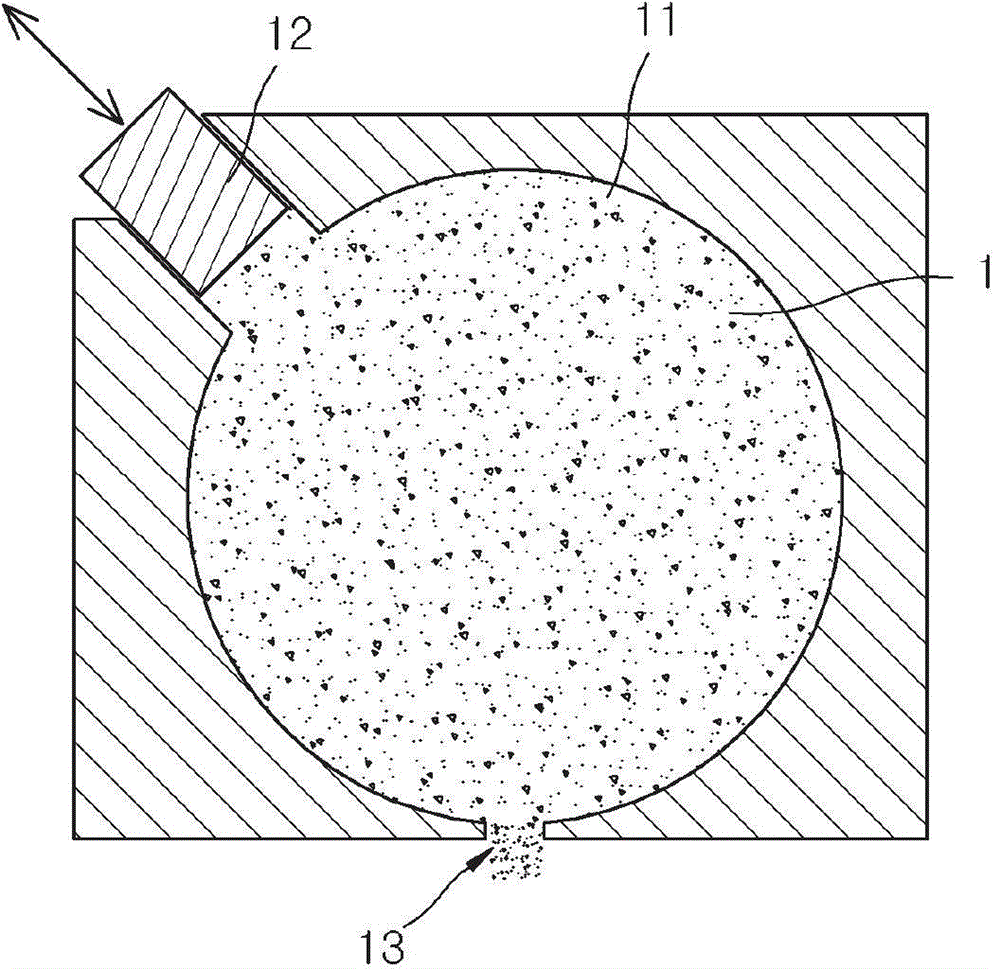

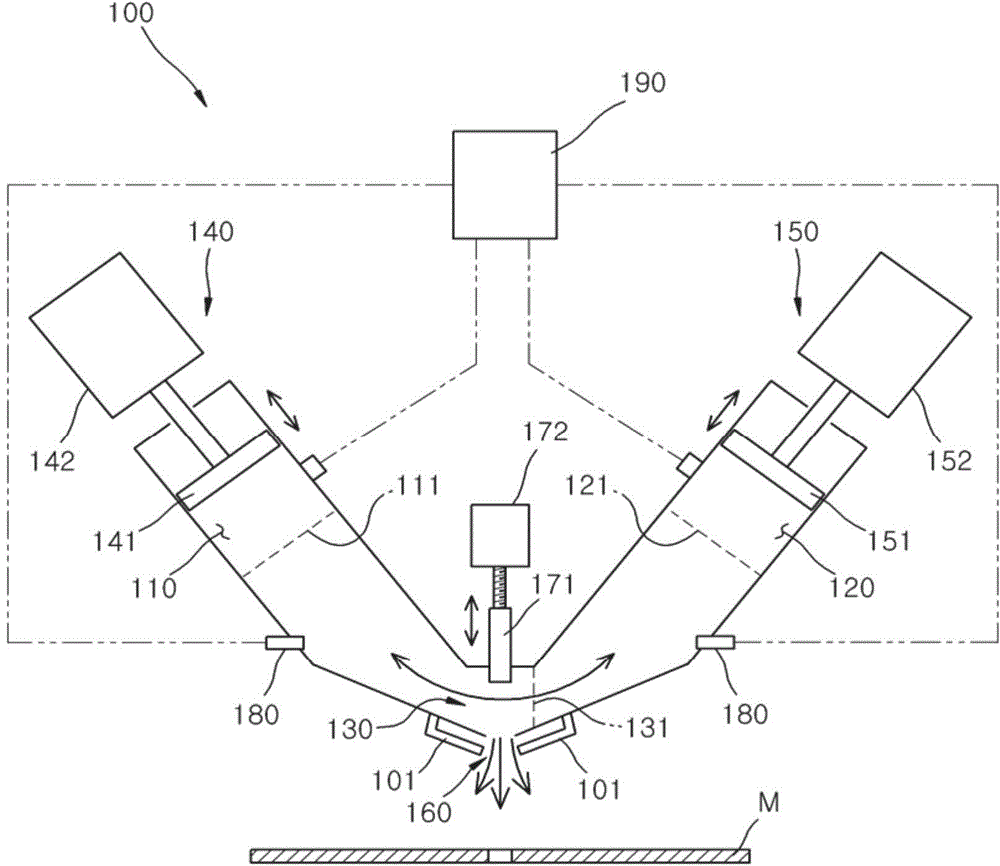

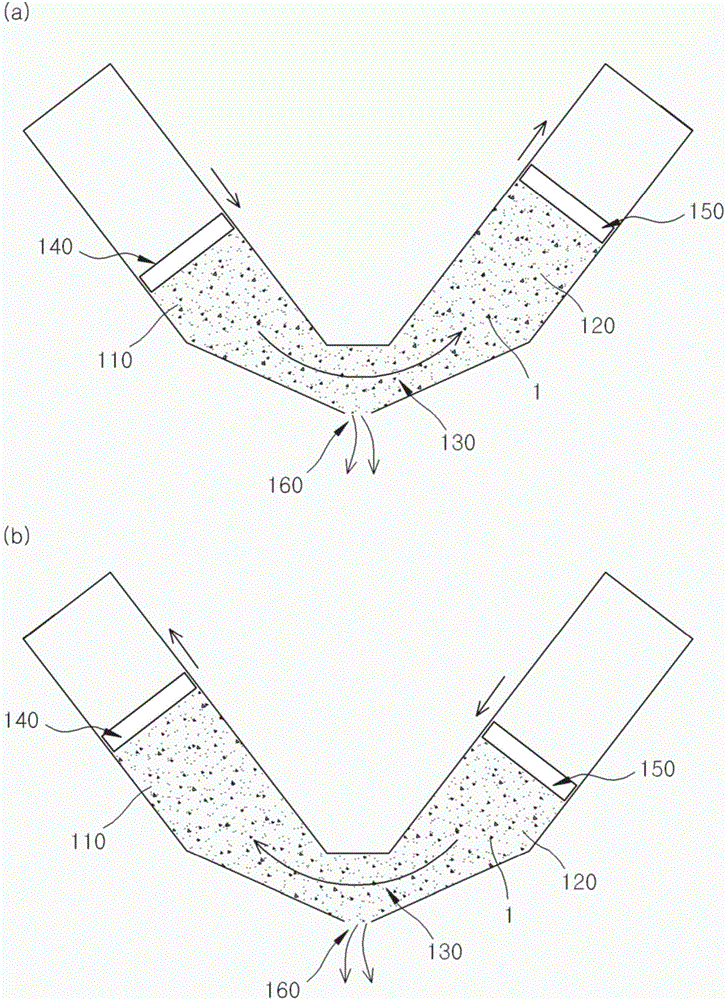

[0024] Hereinafter, embodiments of an apparatus for supplying solder paste according to the present invention will be described with reference to the accompanying drawings.

[0025] figure 2 To show a view of an apparatus for supplying solder paste according to a first embodiment of the present invention, image 3 for illustration figure 2 A view of the operating principle of the device for supplying solder paste in, and Figure 4 for illustration figure 2 A view of the operating status of the device for supplying solder paste in .

[0026] refer to Figure 2 to Figure 4 , the device 100 for supplying solder paste according to the first embodiment of the present invention includes a first chamber 110, a second chamber 120, a bottle neck connection 130, a first booster 140, a second booster 150, a nozzle 160, closing plate 171, closing driver 172, sensor 180, storage 190, blade 101, and vertical driver, wherein the device 100 for supplying solder paste according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com