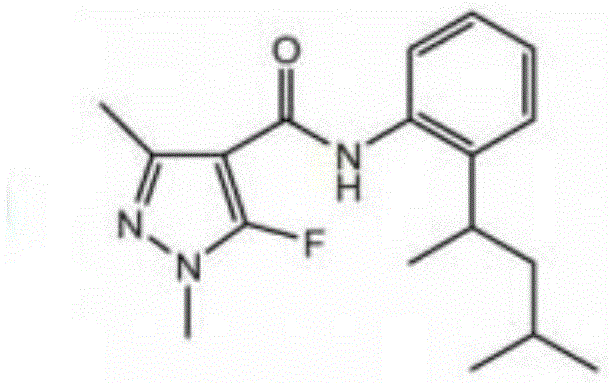

A bactericidal composition containing penflufen and carvacrol and its application

A technology of penflufen and carvacrol, which is applied in the direction of fungicides, biocides, applications, etc., can solve the problems of loss and wheat production reduction, and achieve the effects of less resistance, improved drug efficacy, and disease synergies obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

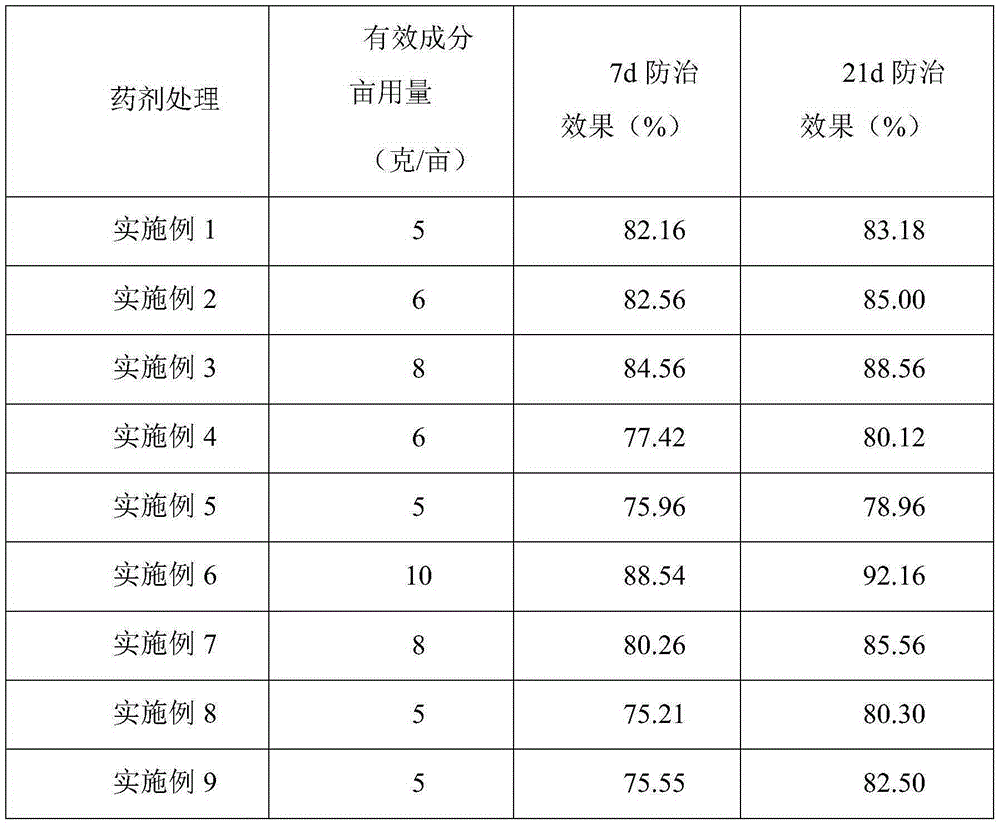

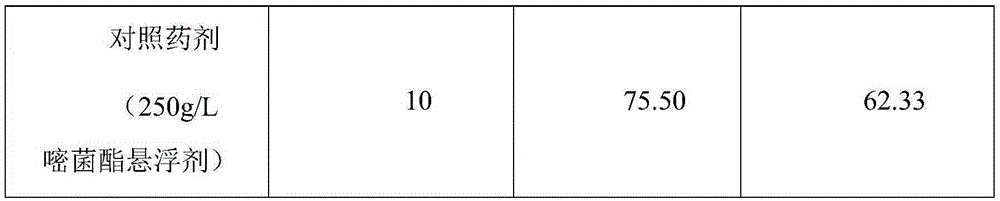

Examples

Embodiment 1

[0021] Example 1: 5% Penflufen·Carvacrol EC formula and production process

[0022] Formula: Penflufen 0.5%, carvacrol 4.5%, ethanol 30%, calcium dodecylbenzenesulfonate 3%, Nongru 1601# 7%, Nongru 6023%, and the rest is ethyl acetate.

[0023] Production process: Put the above formula into a stirred reactor according to the proportion. The total processed materials are 1000kg, the stirring is turned on, the stirring speed is 80r / min, and the material is discharged after stirring for 20 minutes. After passing the test, it is divided into 5% penpyridine·· Carvacrol EC.

Embodiment 2

[0024] Example 2: Formula and production process of 10% penflufen·carvacrol wettable powder

[0025] Formula: Penflufen 2%, carvacrol 8%, open powder 5%, sodium lignosulfonate 5%, sodium lauryl sulfate 1.5%, white carbon black 10%, and the rest is kaolin.

[0026] Production process: Put the above formula into the non-gravity stirring tank according to the proportion, the total processing material is 1000kg, turn on the stirring, after 15 minutes of stirring, enter the airflow pulverization, after completion, enter the non-gravity stirring tank again, and discharge after 15 minutes of mixing. After passing the 325-mesh sieve, sub-packaging after passing the content test to obtain 10% penflufen·carvacrol wettable powder.

Embodiment 3

[0027] Example 3: Formula and production process of 30% penflufen·carvacrol wettable powder

[0028] Formula: Penflufen 15%, carvacrol 15%, open powder 7%, sodium lignosulfonate 7%, sodium lauryl sulfate 2%, silica 15%, and the rest is kaolin.

[0029] Production process: Put the above formula into a stirred reactor in proportion, the total processed material is 1000kg, turn on the stirring, the stirring speed is 80r / min, after stirring for 20 minutes, the material is discharged, and after the test is qualified, it is divided into 30% penpyridine· Carvacrol wettable powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com