Production process of conical mud door

A manufacturing process and tapered technology, applied in the field of tapered mud door manufacturing process, can solve problems such as difficult positioning and precision, and achieve the effect of improving production efficiency and ensuring production accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

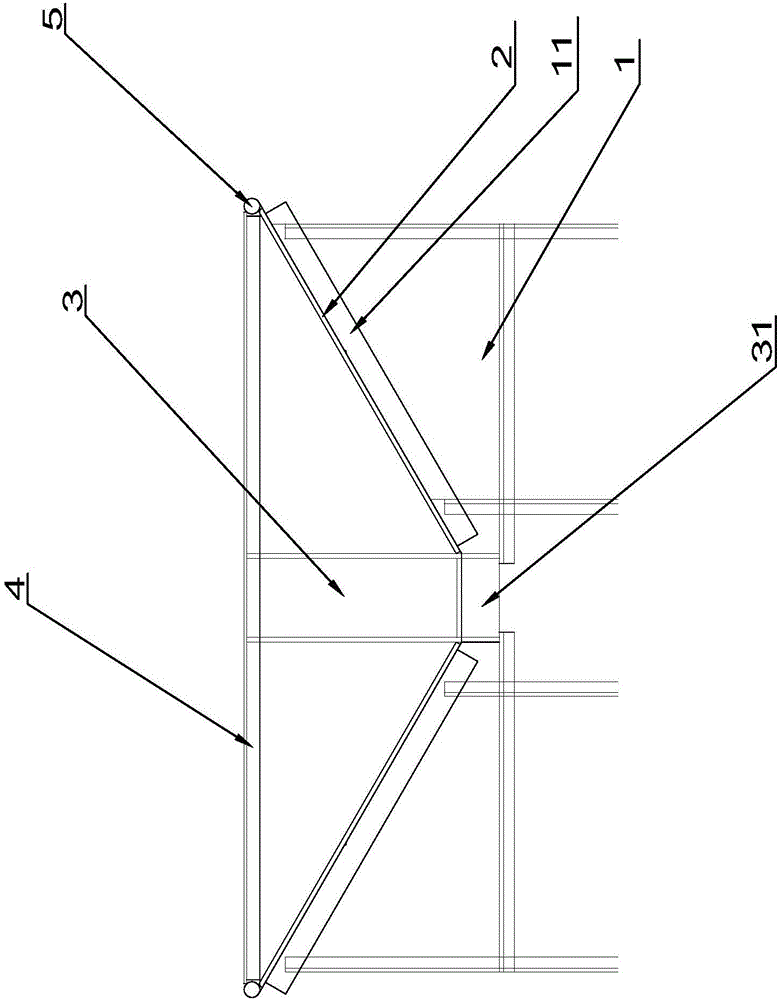

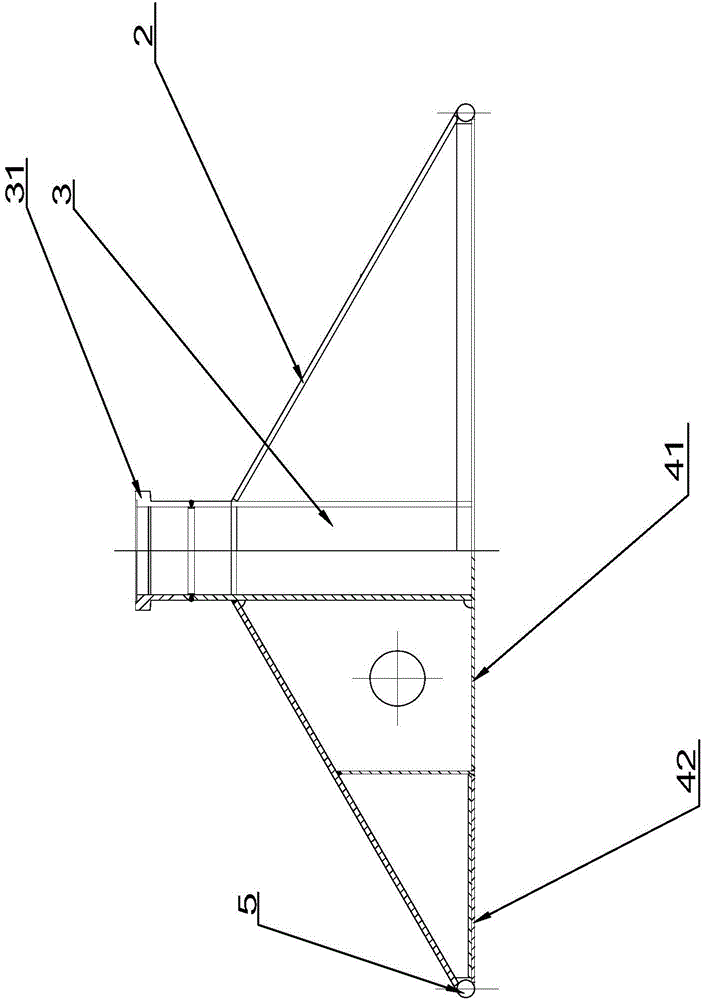

[0020] refer to figure 1 , figure 2 , the present invention is a kind of manufacturing process of tapered mud door, comprises the following steps:

[0021] 1) Assemble the tooling platform 1 with an inverted conical inner cavity, set a number of conical formworks 11 uniformly distributed at equal angles in the tooling platform 1, the inclination of each conical formwork 11 is equal to the inclination of the cone generatrix of the conical panel 2 degree, and complete the ground sample marking under the tooling platform 1, and determine the center of the flange pipe 3 and the flange 31;

[0022] 2) Divide the conical panel 2 into several parts according to the circumference and equal angles for blanking and bending processing to form several conical panel assemblies;

[0023] 3) Put each conical panel assembly upside down on the tooling platform 1 for assembly, and form a complete conical panel 2 by welding after the assembly is completed;

[0024] 4) Install the flange tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com