A positioning fixture for an automobile brake caliper bracket

A technology for automobile braking and positioning fixtures, applied in positioning devices, manufacturing tools, clamping and other directions, can solve the problems of low production efficiency, high labor intensity of workers, non-connection, etc., and achieve convenient positioning, simple structure, convenient automatic processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

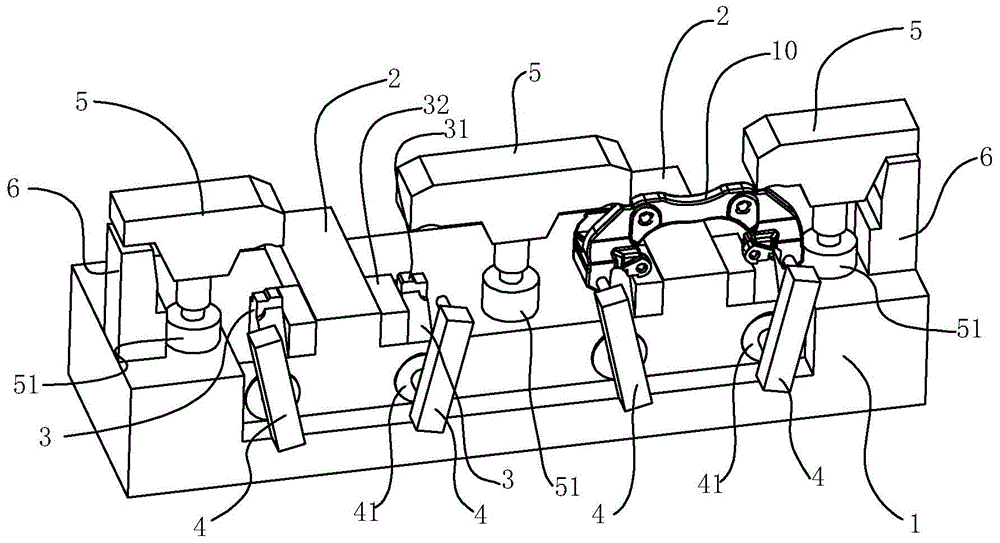

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

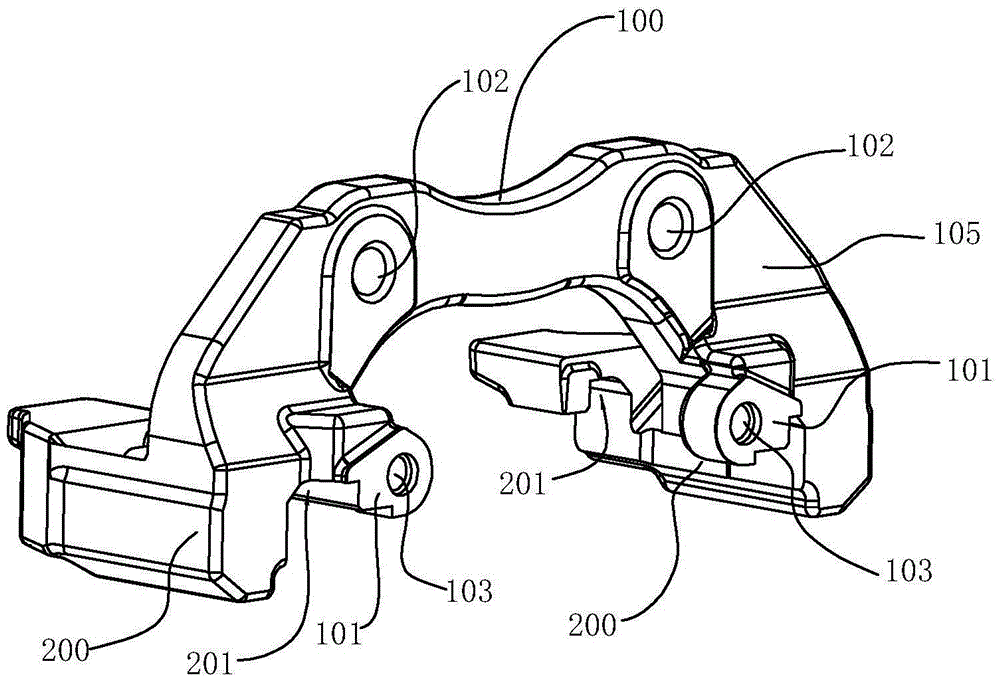

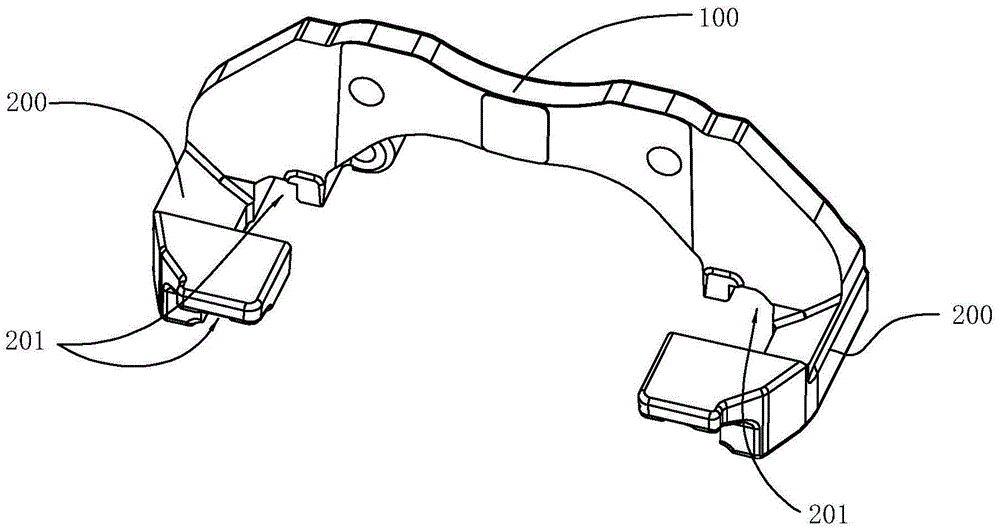

[0016] Such as Figure 1-2 As shown, it is a three-dimensional schematic diagram of an automobile brake caliper bracket, which includes a front panel 100 in the middle, and side portions 200 extending backward from both sides of the front panel 100, the front panel 100 is an irregular The approximate bridge-shaped plate, the two ends are downward, and the middle is upward compared with the two ends. Both sides of the lower part of the front panel 100 are provided with protrusions 101 protruding forward, and the upper position of the protrusion 101 of the front panel 100 needs to be processed into two M12 threaded holes 102. Each is provided with an M9 threaded hole 103 . The two sides of the lower surface of the front panel 100 of the brake caliper bracket 10 are also provided with a groove 201 extending in the same direction as the side part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com