An automatic processing system for frame type circuit breaker busbar

An automatic processing and circuit breaker technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity, unstable processing quality, and low processing efficiency, and achieves convenient operation, simple structure, and automatic Processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0043] The directions of up, down, front, back, left, and right in the text are explained based on the direction of the arrow in the illustration, and the actual settings are deduced by analogy.

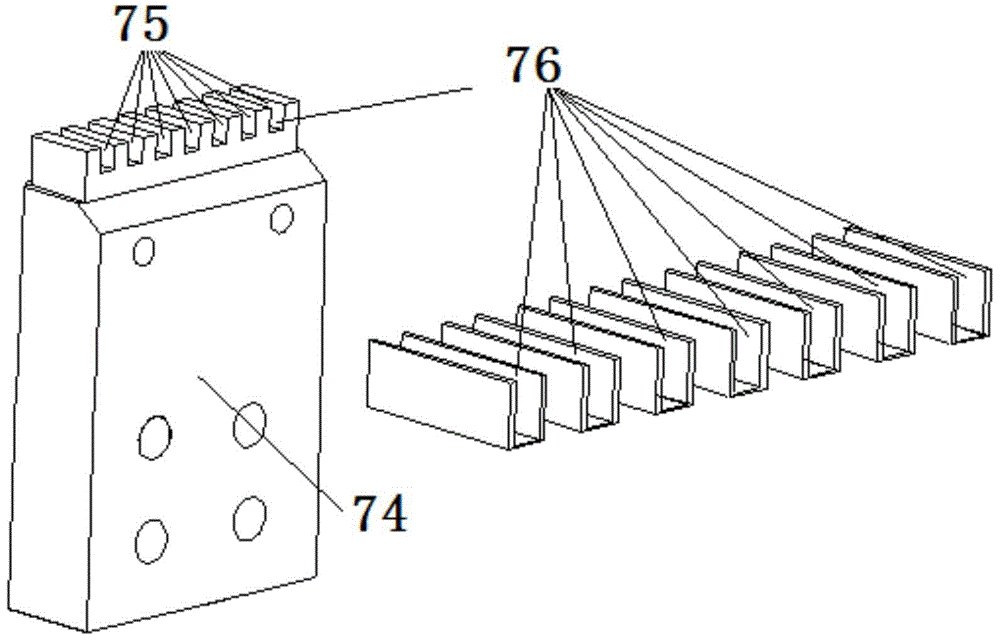

[0044] refer to figure 1 , the structure of the busbar 4 as the assembly object of the present invention is that a plurality of U-shaped welding wire grooves 75 are arranged side by side on the upper end of the base body 74, and each U-shaped welding wire groove 75 needs to be assembled with a formed U-shaped welding wire 76. The three outer surfaces (U-shaped bottom surface and U-shaped two outer sides) of each U-shaped welding wire 76 fit well with the U-shaped welding wire groove 75 .

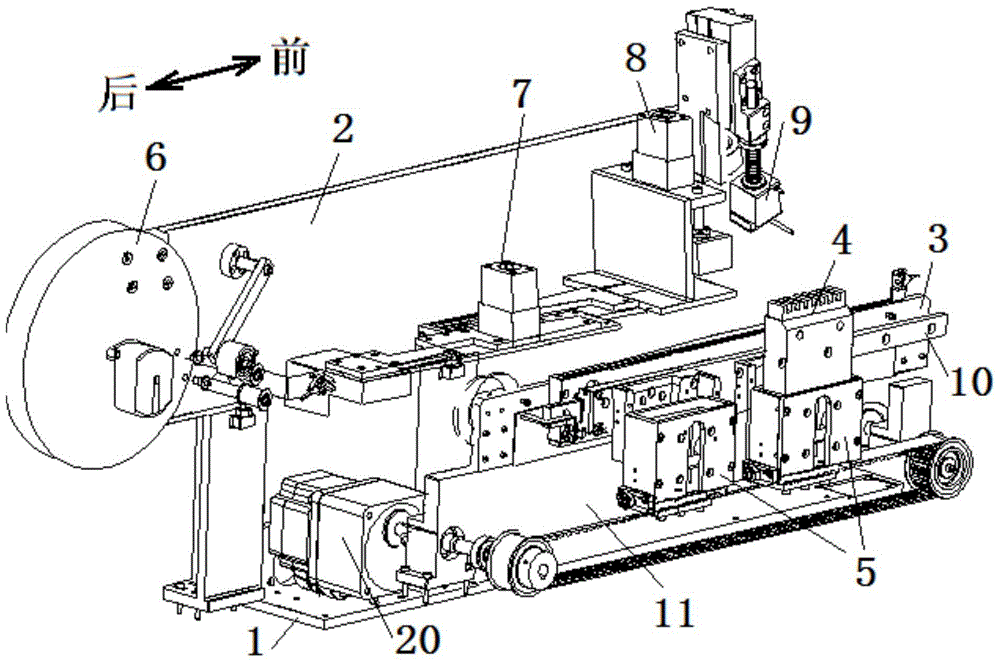

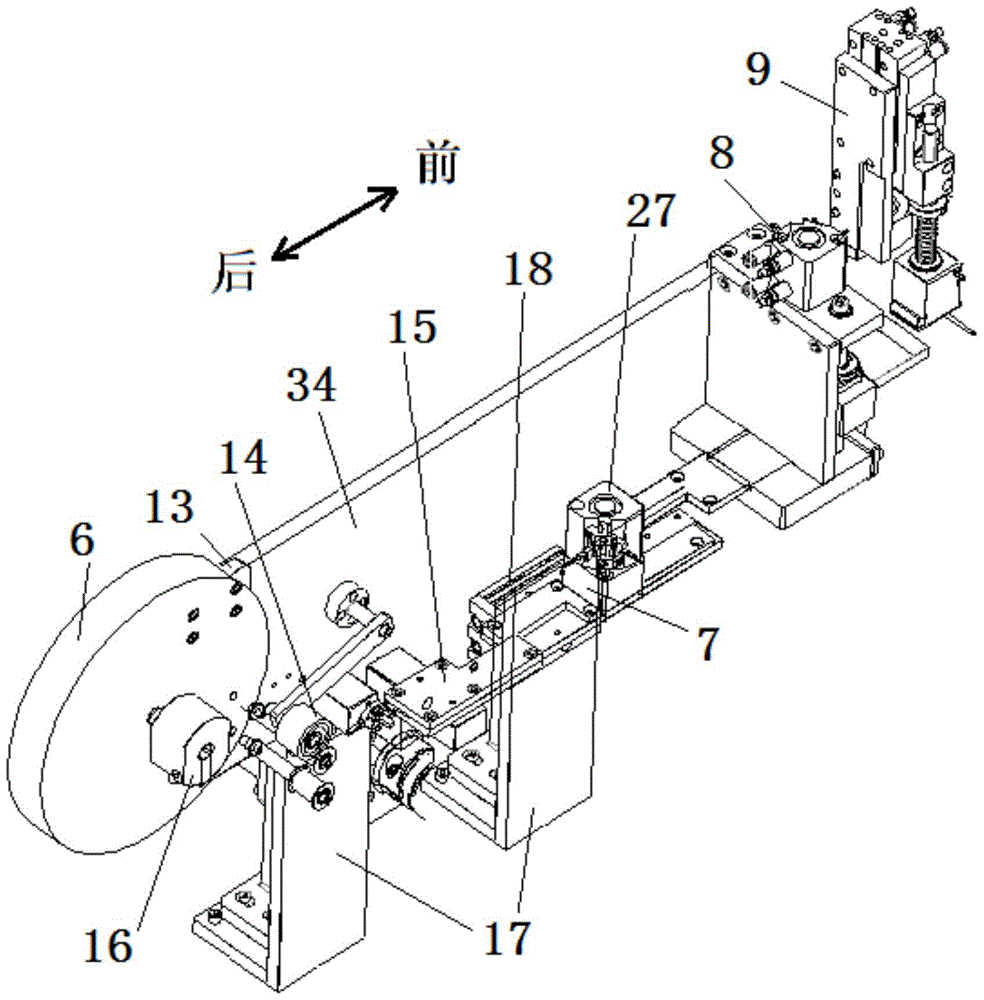

[0045] refer to figure 2 , the overall structure of the frame-type circuit breaker busbar automatic processing system of the present invention is that it inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com