Axial pressing locking device

A locking device, axial technology, applied in the direction of grinding workpiece support, etc., to achieve the effect of convenient use, firm and reliable fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

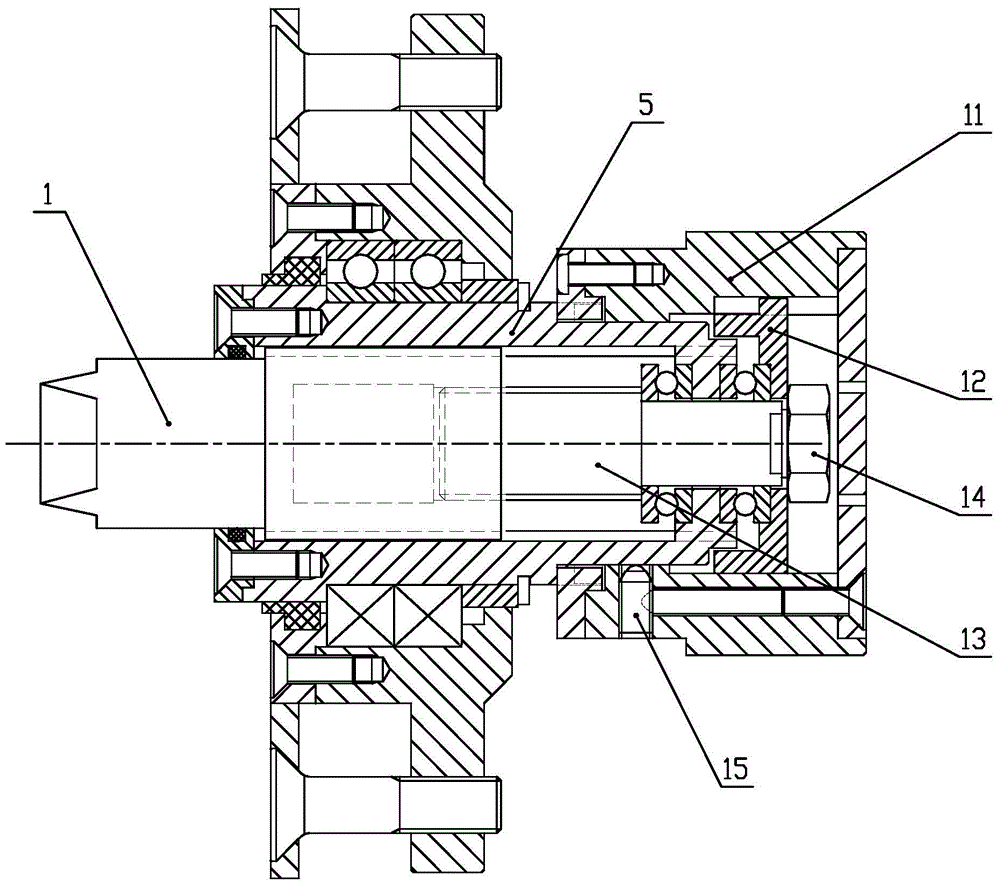

[0040]In this embodiment, the rotating part adopts the rotating shaft 13 , and the anti-rotation adjusting part adopts an assembly composed of a rotating handle 11 , an anti-rotation ring 12 and a ball screw 15 .

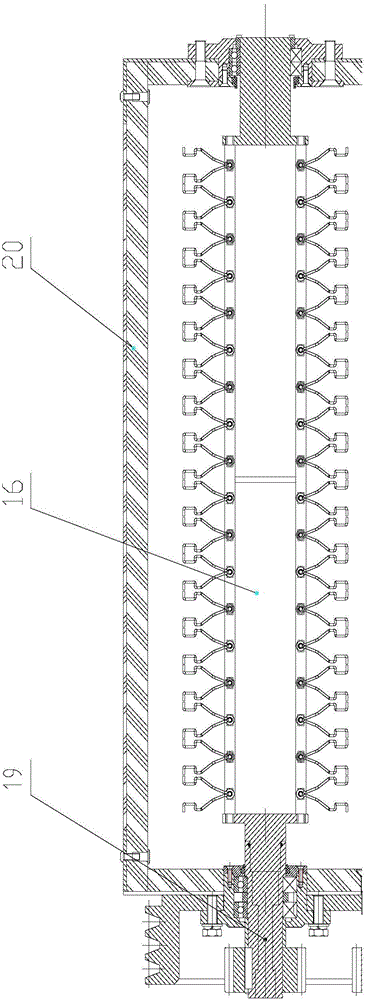

[0041] The specific structure is as image 3 As shown, the axial compression locking device includes a compression shaft 1 and a compression sleeve 5, one end of the compression shaft 1 is inserted into the sliding cavity of the compression sleeve 5, and the compression shaft 1 and the compression sleeve 5 sliding cavity The cross-section of the shaft adopts a square cross-section or adopts anti-rotation shapes such as splines, so that the compression shaft 1 can only slide axially in the compression sleeve 5 and cannot rotate, so as to transmit torque. In the compression shaft sleeve 5, a rotating shaft 13 is also installed by bearings. The installation requirements of the rotation shaft 13 can only be rotated in the compression shaft sleeve 5 without axial displac...

Embodiment 2

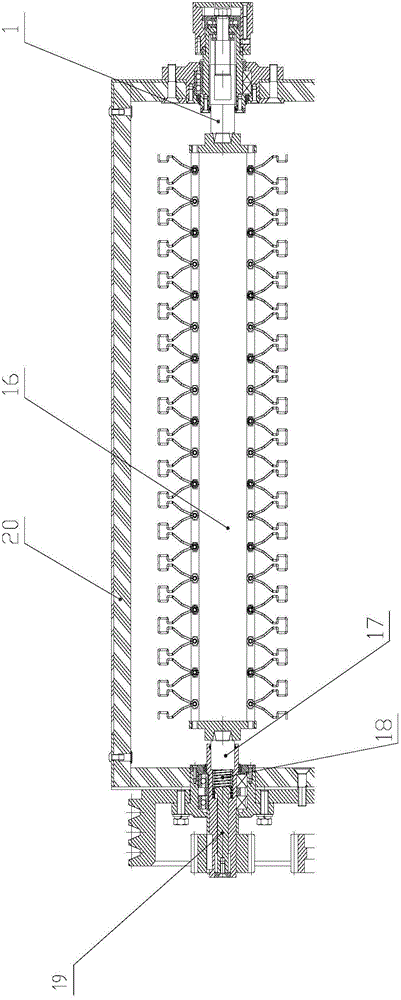

[0044] Such as Figure 4 As shown, in the axial compression locking device in this embodiment, the rotating part adopts the nut 2 , and the anti-rotation adjusting part also adopts a structure different from that in the first embodiment, mainly the inner and outer spline sleeves 3 . The specific structure is described as follows: the axial compression locking device includes a compression shaft 1 and a compression sleeve 5. Similarly, one end of the compression shaft 1 is inserted into the sliding cavity of the compression sleeve 5, and the compression shaft 1 and the compression sleeve 5 The cross section of the sliding cavity adopts a square cross section or anti-rotation shape such as a spline, so that the compression shaft 1 can only slide axially in the compression sleeve 5 and cannot rotate, so as to transmit torque. The right end of the pressing shaft 1 is provided with an external thread to form a screw rod, and the nut 2 as a rotating part is installed on the screw ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com