Device for checking the construction of an extruder screw

A technology of extruding screw and extruder, which is applied in the field of devices for inspecting the structure of extruding screw, and can solve problems such as difficult to eliminate plugging errors and failure to achieve working results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

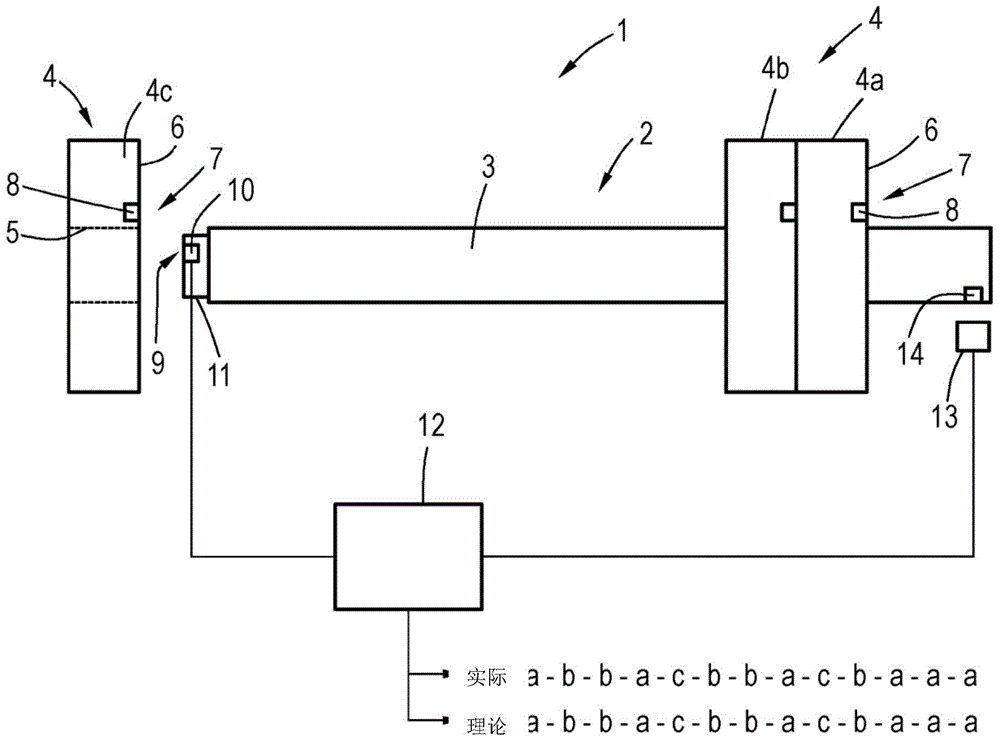

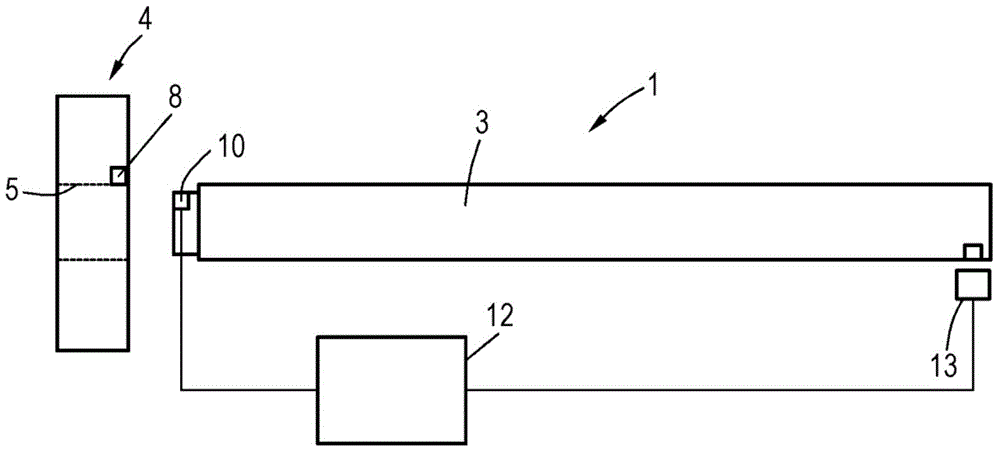

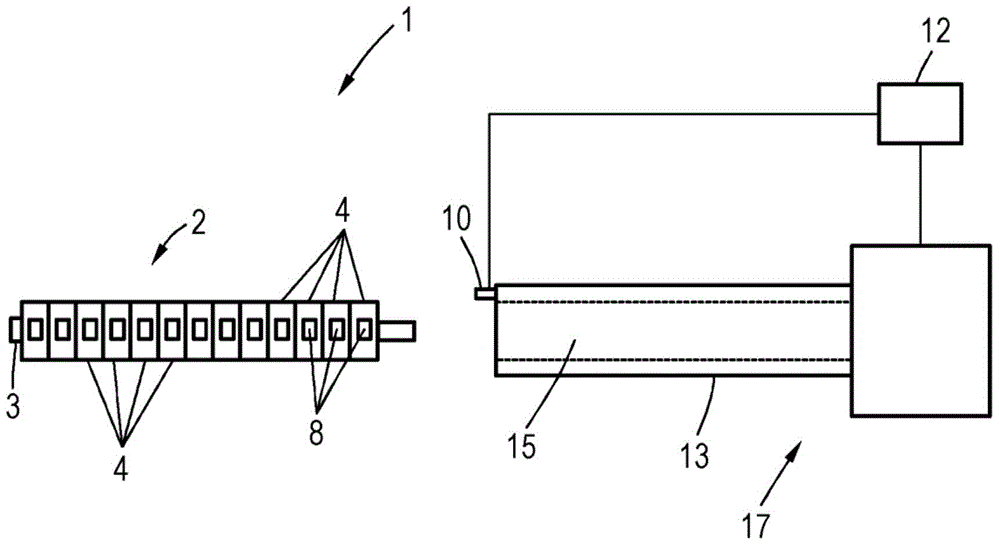

[0038] figure 1 A device 1 according to the invention for checking the configuration of an extrusion screw 2 is shown. The extrusion screw 2 comprises a shaft 3 on which screw elements 4 are pushed on in seemingly arbitrary order. The shaft has an external toothing, and each screw element 4 has a corresponding internal toothing in the area of its bore 5 , wherein the external toothing and the internal toothing mesh with each other, whereby a torsionally fixed connection is produced. The principle construction of such plug-in extrusion screws has long been known.

[0039] In the device 1 according to the invention, each screw element 4 has a storage element 7 on its end face 6 , here in the form of a transponder 8 . Each transponder 8 contains stored information which identifies the respective screw element 4 .

[0040] In principle, a general distinction is made between three different screw element families, namely the conveying elements as well as the mixing elements an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com