V-shaped thrusting rod assembly for rear suspension of heavy truck

A heavy-duty vehicle and rear suspension technology, which is applied to the suspension, vehicle parts, cantilever mounted on the pivot, etc., can solve the problem of poor taper fit between the inner and outer taper holes, lower overall rigidity of the inner ring, car overturn and death, etc. problems, to achieve the effect of saving materials, reducing wear, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

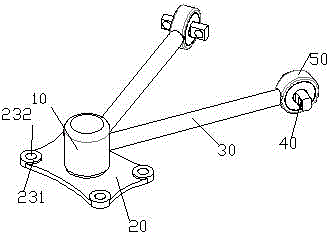

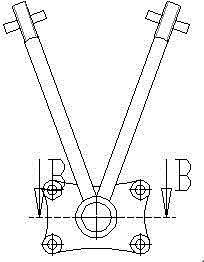

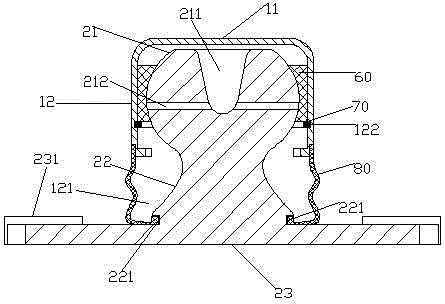

[0034] combine Figure 1-3 Description: A V-shaped thrust rod assembly for the rear suspension of a heavy-duty vehicle, including a straight ball seat 30, a ball pin assembly 40, a connecting pipe 50, a middle ball seat 10, an outer ring of a joint bearing 60, a mounting seat 20, and an elastic retainer Ring 70 and sealing sheath 80;

[0035] The middle ball seat 10 includes an upper cover 11 and a housing 12;

[0036] The upper cover 11 and the housing 12 are integrally formed; the housing 12 is provided with a cavity 121 inside, and the end of the cavity 121 away from the upper cover 11 is provided with a ring groove 122;

[0037] The mounting seat 20 includes a flat-headed sphere 21, a rotating body 22 and a flange 23;

[0038] The rotator 22 is located between the flat sphere 21 and the flange 23, and the rotator 22 is smoothly connected with the flat sphere 21 and the flange 23; the flat sphere 21 and the outer ring of the joint bearing are assembled into a pair of fric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com