A double-rolling mechanism in the machine for medical gauze air-jet loom

An air-jet loom and gauze technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problem of inability to adapt to the working conditions of framing, and achieve the effects of convenient fixed operation, increased distance and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

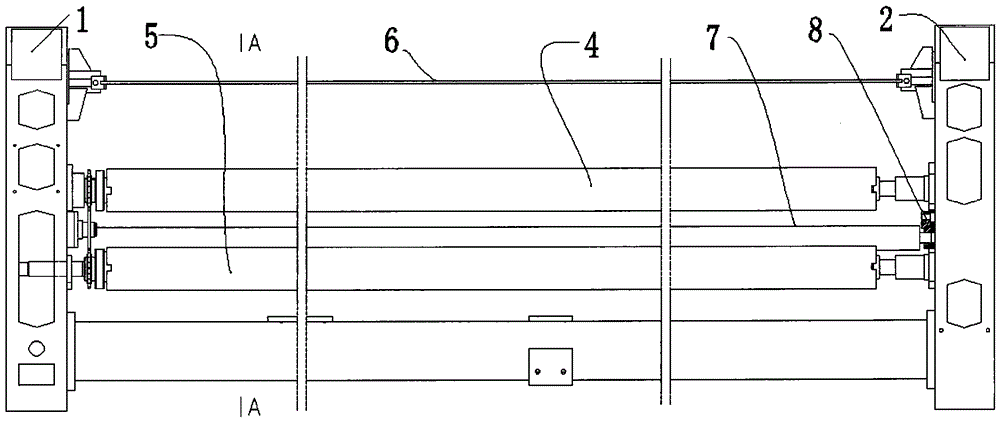

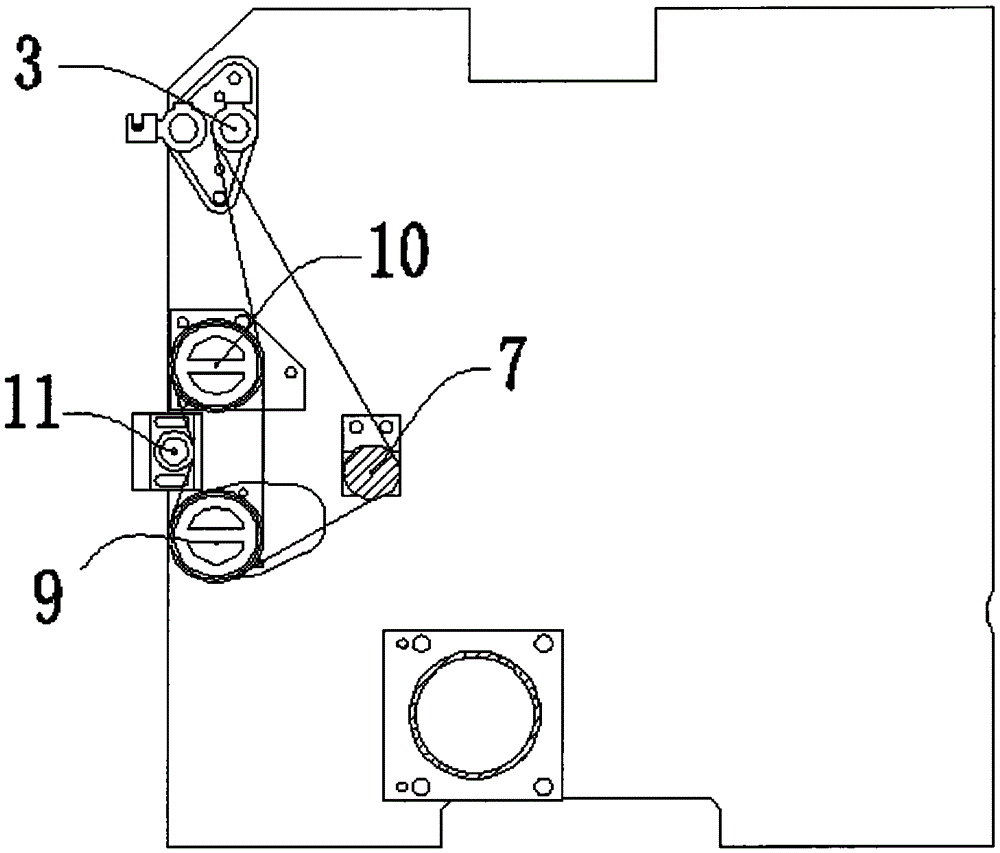

[0014] Such as figure 1 , 2 As shown, a kind of machine double-rolling mechanism for medical gauze air-jet loom of the present invention comprises upper cloth guide roller 3, upper cloth roll 4, lower cloth roll 5, lower cloth guide roller 7, active Sprocket 9, driven sprocket 10 and dust bar 6, wherein upper cloth guide roller 3, upper cloth roll 4, lower cloth roll 5, lower cloth guide roller 7, driving sprocket 9, driven sprocket 10 and the dust-proof rod 6 are all arranged between the front upper beam and the front lower beam, and the upper cloth guide roller 3, the upper cloth roll 4, the lower cloth roll 5, the lower cloth guide roller 7, and the two ends of the dust-proof rod 6 are respectively Connected with the left wall panel 1 and the right wall panel 2, the upper cloth roll 4 and the lower cloth roll 5 are arranged directly below the upper cloth guide roller 3 from top to bottom, and the lower cloth guide roller 7 is arranged horizontally on 7 On the rear side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com