Mechanical structure of novel high-speed rail track measuring instrument

A technology of mechanical structure and measuring instrument, applied in the field of control, can solve the problems of large display error, large cumulative error, and different measurement effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

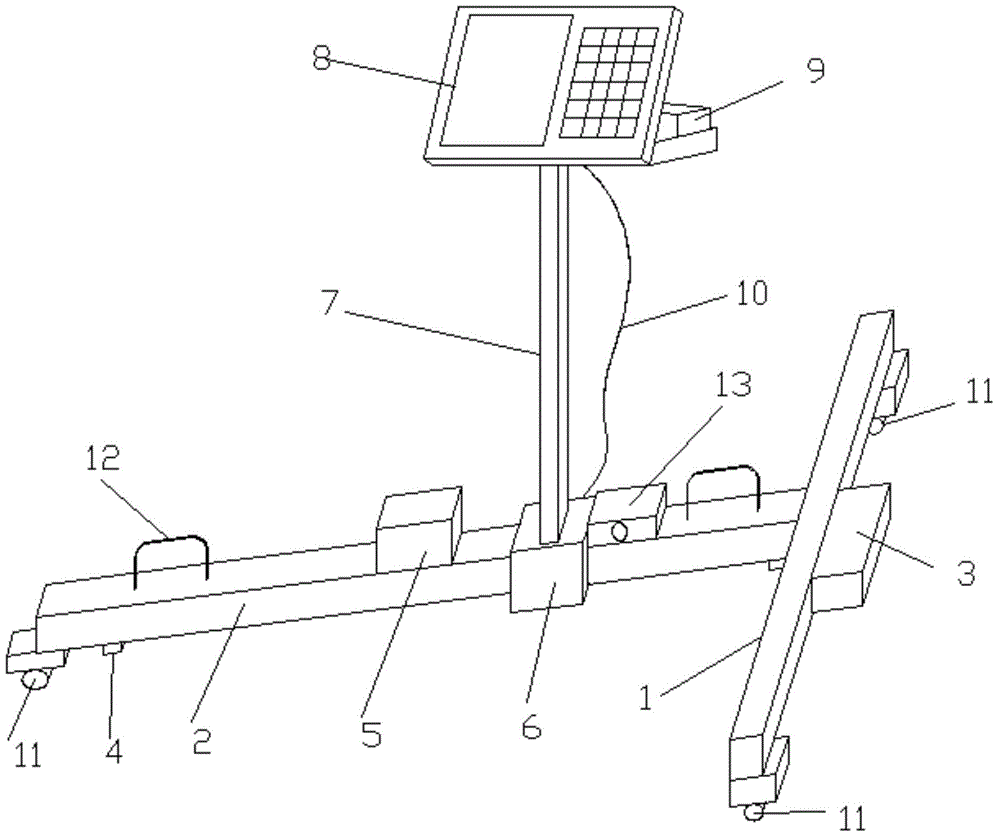

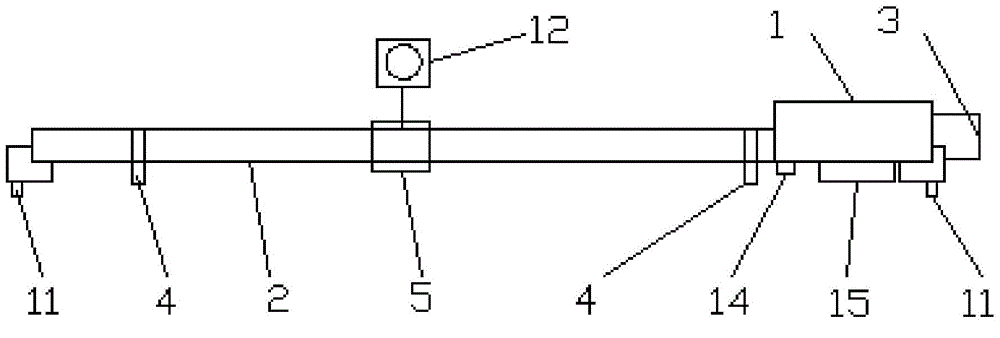

[0010] As shown in Figure 1 and Figure 2, the present invention mainly consists of a beam 2, a longitudinal beam 1, a high and low optical fiber gyroscope mechanism 3, a displacement sensor 4, an inclination sensor mechanism 5, a connecting block 6, a support frame 7, a display screen 8, Controller 9, connecting wire 10, walking wheel 11, handle 12, battery box 13, encoder 14 and rail-to-optical fiber gyroscope mechanism 15 constitute.

[0011] In this example, the beam 2 is fixedly connected to the longitudinal beam 1, and the beam 2 is located in the middle of the longitudinal beam 1, and the beam 2 and the longitudinal beam 1 form a T-shaped structure. The inclination sensor mechanism 5 is installed in the middle of the crossbeam 2, the orbital fiber optic gyroscope mechanism 15 and the high and low fiber optic gyroscope mechanism 3 are installed on the longitudinal beam 1, and the inclination sensor mechanism 5 is combined with the compensation of the high and low fiber opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com