Flanged groove type FRP (Fiber Reinforce Plastic) plate-concrete combination bridge deck

A FRP board and concrete technology, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of longitudinal torsion and other problems, achieve the effect of improving stiffness and stability, eliminating local stability problems, and speeding up construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

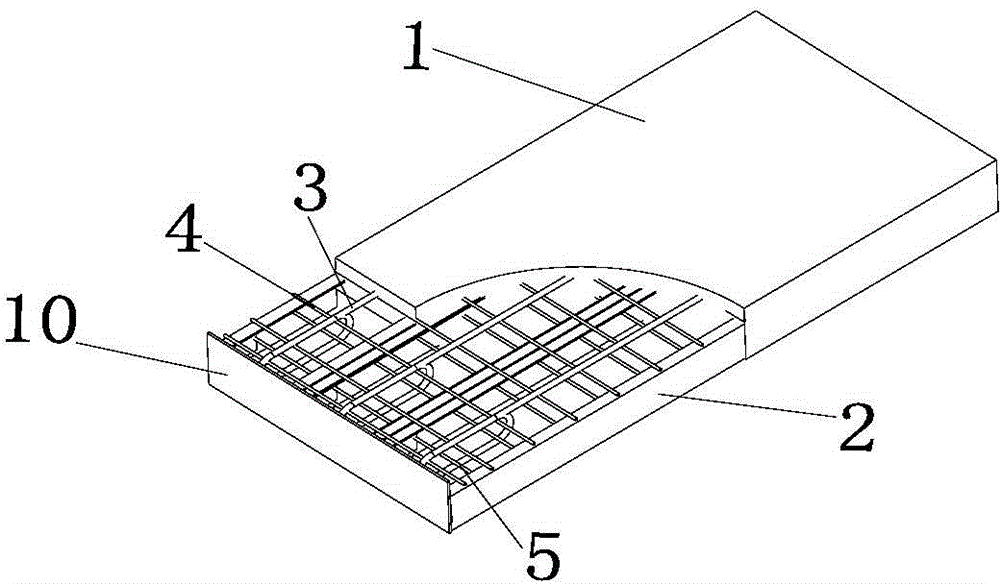

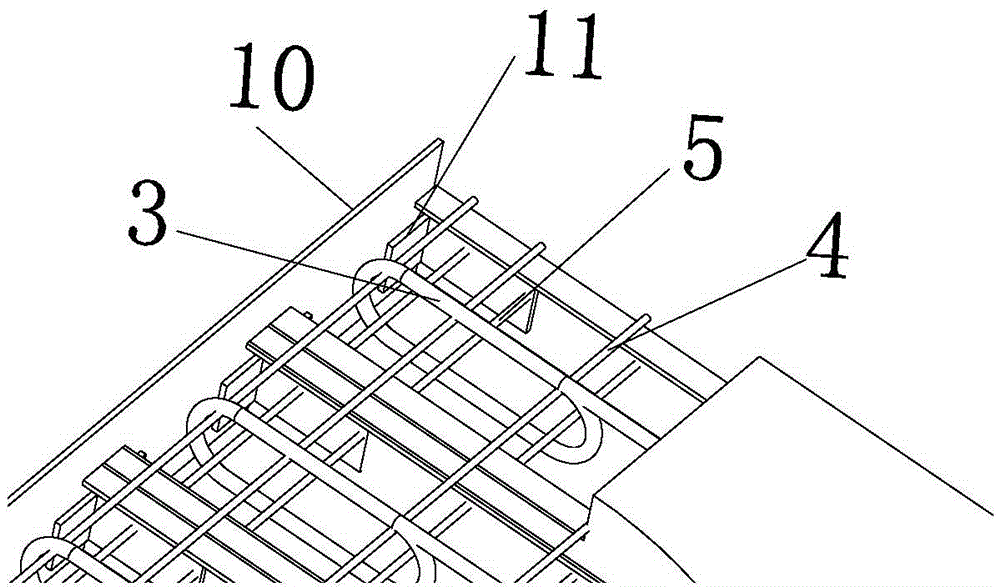

[0037] During the construction process, the FRP baffle 10 is connected with the single-piece grooved FRP board 2 with flanges to become the FRP board template under construction. The penetrating ribs 5 tightly connect several single-piece grooved FRP panels 2 into one body, and play a fastening role; the longitudinal bridge top ribs 4 and the penetrating ribs 5 on the top of the FRP panels jointly bear the bending load in the longitudinal bridge direction.

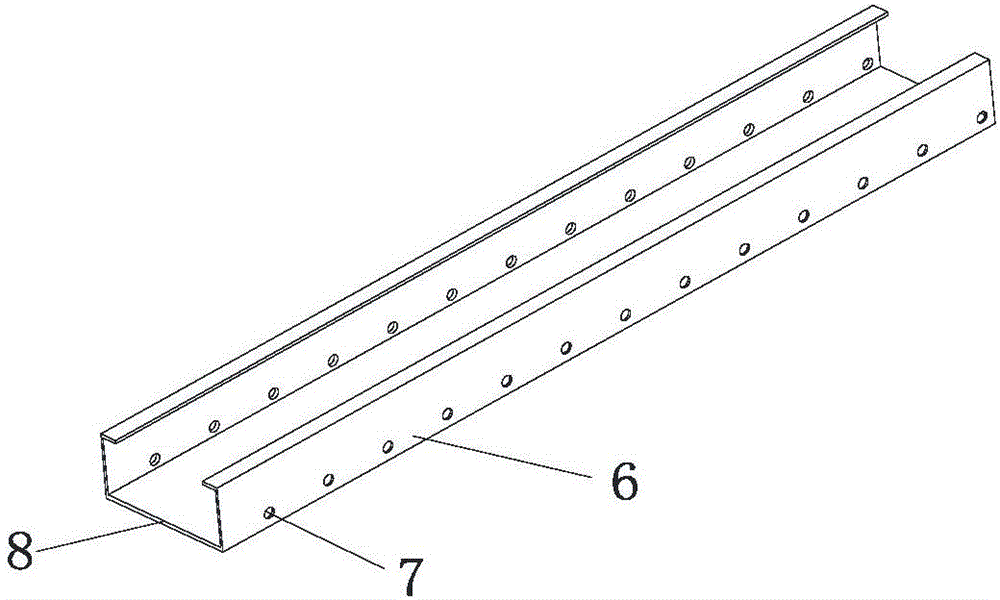

[0038] The traditional channel-type FRP plate improves the rigidity of the formwork by increasing the height of the rib plate, but the higher rib plate reduces the stability of the formwork during construction; the present invention adopts a single-piece channel-type FRP plate with flange 2 , to improve the stability of the formwork through the constraints of the flange on the ribs. The height of the inverted L-shaped rib 6 and the width of the flange are determined according to the span of the composite slab and the const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com