Fish-shaped steel tube pile

A steel pipe pile, fish-shaped technology, applied in sheet pile walls, buildings, foundation structure engineering, etc., can solve the problem of low torsional load capacity, and achieve the effect of strong torsional resistance, good stability, and control of horizontal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

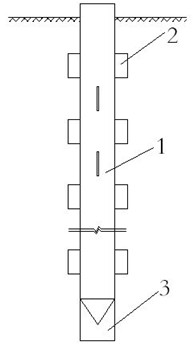

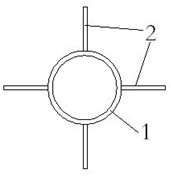

[0031] Such as figure 1 , image 3 As shown, the present invention welds multi-layer side fins 3 sequentially from top to bottom on the side of the steel pipe pile 1 closed at the bottom, and each layer of side fins 3 has 2 to 4 pieces; the tail fin is welded on the side of the tapered tip of the steel pipe pile closed at the bottom slice 3.

[0032] Such as Figure 4 As shown, the side wings are rectangular (a), inverted right triangle (b), inverted trapezoid (c), combination of rectangle and inverted trapezoid (d) or combination of rectangle and sector (e) .

[0033] Such as Figure 5 Shown is the front view (a) and side view (b) of an optional shape diagram of the tail fin of the closed steel pipe pile, the bottom end of the tail fin is a straight line; as Figure 6 Shown are the front view (a) and the side view (b) of another alternative shape diagram of the tail fin of a closed-end steel pipe pile, where the bottom end of the tail fin is the tip.

[0034] Each laye...

Embodiment 2

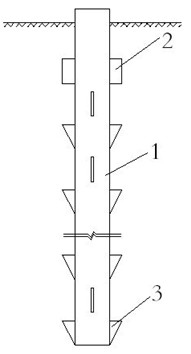

[0037] Such as figure 2 , image 3 As shown, the side of the steel pipe pile 1 with the bottom opening is welded in sequence from top to bottom with multiple layers of side fins 2, and each layer of side fins is 2 to 4; There are 2 to 4 tail fins.

[0038] Such as Figure 4 As shown, the side fins and tail fins are rectangular (a), inverted right triangle (b), inverted trapezoid (c), combination of rectangle and inverted trapezoid (d) or combination of rectangle and sector (e).

[0039] Each layer of the multi-layer side wings can be arranged in a staggered equidistant or staggered unequal distance, figure 2 In the middle, there are two symmetrical arrangements of side wings on each layer, and the side wings between the two layers are arranged staggered and equidistant. The side wings welded on the side of the steel pipe pile can be a combination of the same or different side wings.

[0040] Whether the tail fins are set or not is determined according to actual needs. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com