Pedal with a pi section provided with tilted ribs for reinforcement in torsion

A technology for reinforcing ribs and pedals, applied in mechanical equipment, foot start devices, mechanical control devices, etc., can solve problems such as the complexity of the pedal manufacturing process, and achieve the effects of effective tools and energy, optimized manufacturing, and large structural rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

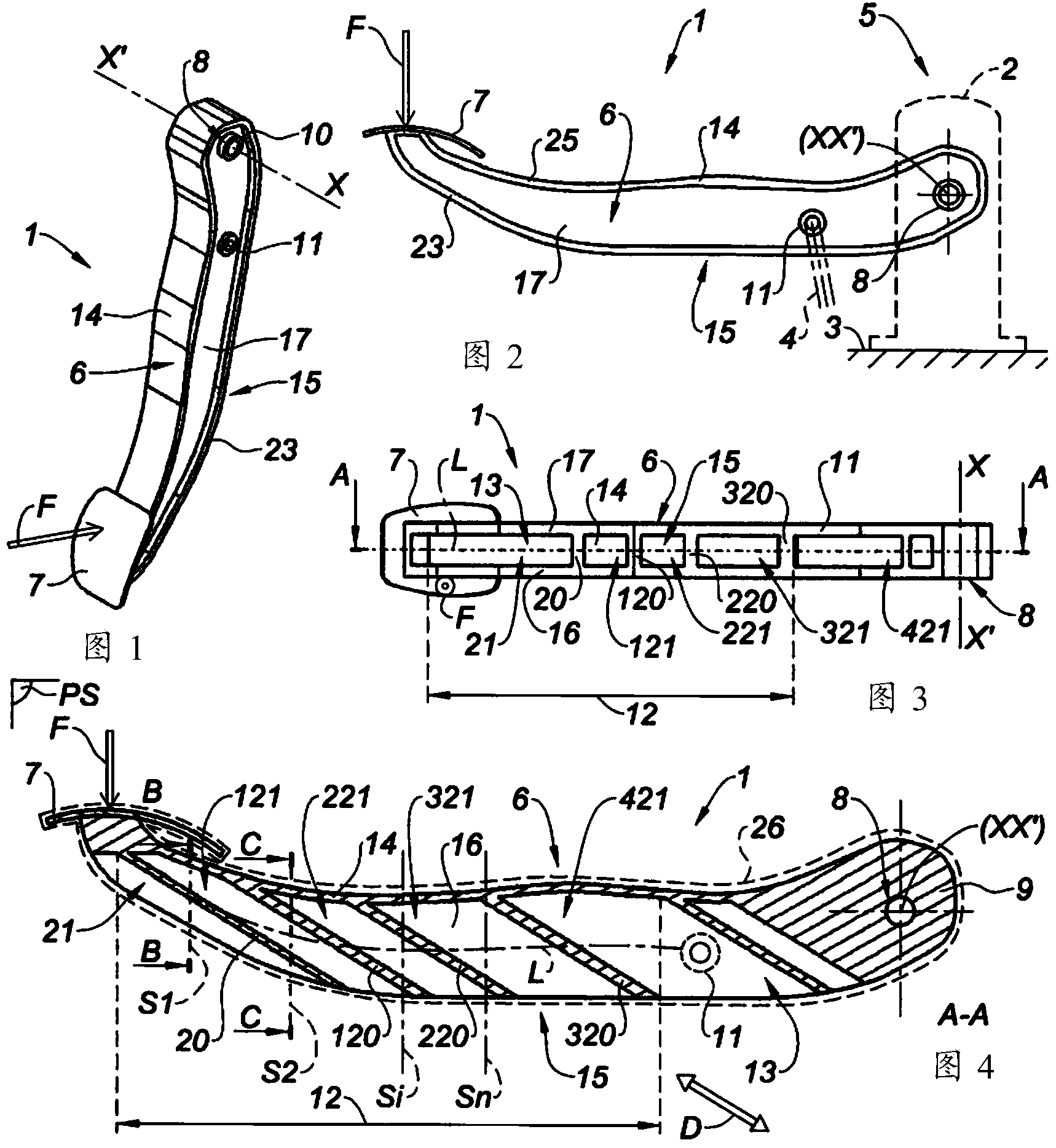

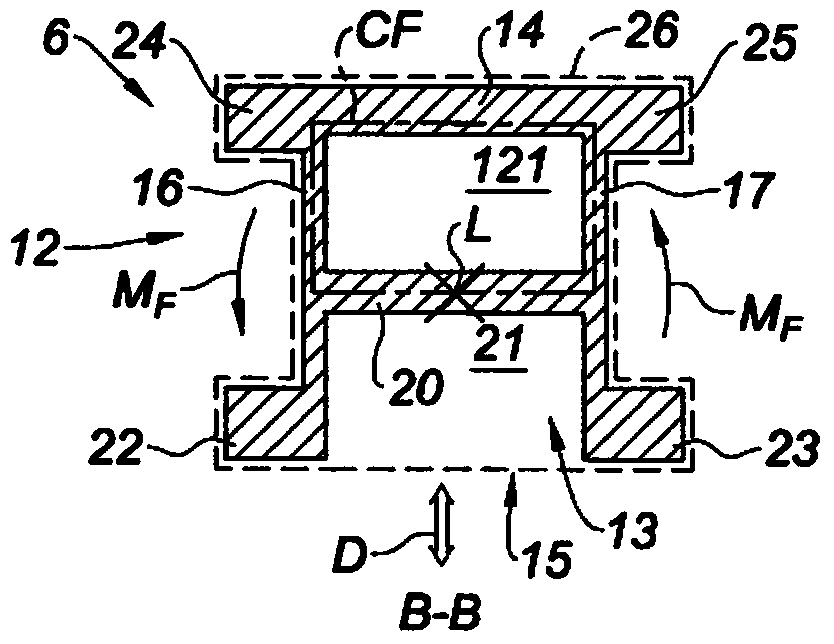

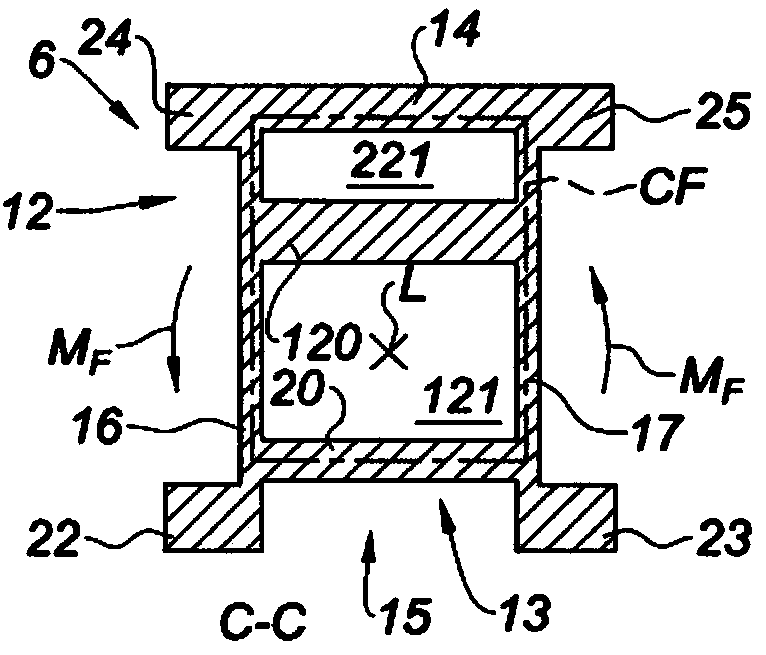

[0056] The present invention relates to a pedal 1 of the control pedal type for actuating any mechanism, and more particularly to a brake pedal designed for application in a vehicle so as to be able to actuate a braking device, preferably an auxiliary braking device.

[0057] For this, and as figure 2 As shown, the pedals are preferably mounted on a base 2, which is itself preferably attached to the vehicle's floor or engine fender 3, said pedals being pivotally hinged to the base 2 about a pivot axis (XX') , so that when pivoting under the stress of a control force F exerted by the user's foot, the pedal can drive an actuator 4, such as a brake lever or a cable, which is preferably in a compressed state.

[0058] Of course, the invention relates to a control pedal assembly 5 comprising at least one pedal 1 , preferably a brake pedal according to the invention, or even a plurality of pedals with one or more pedals 1 according to the invention.

[0059] The invention also rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com