Simple micro-added resistance large-deformation anchorage device and method

An anchoring device and large deformation technology, which is applied in the direction of earth drilling, bolt installation, mining equipment, etc., can solve the problems of small anchor cable elongation, fracture, and increased anchor cable stress, so as to improve the supporting force and maintain The effect of stabilizing and improving the support endurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings:

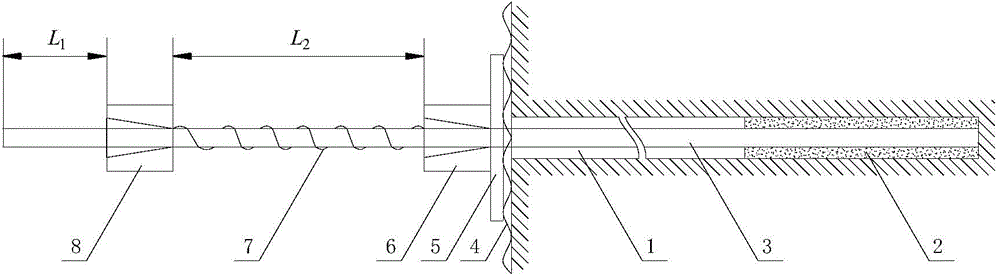

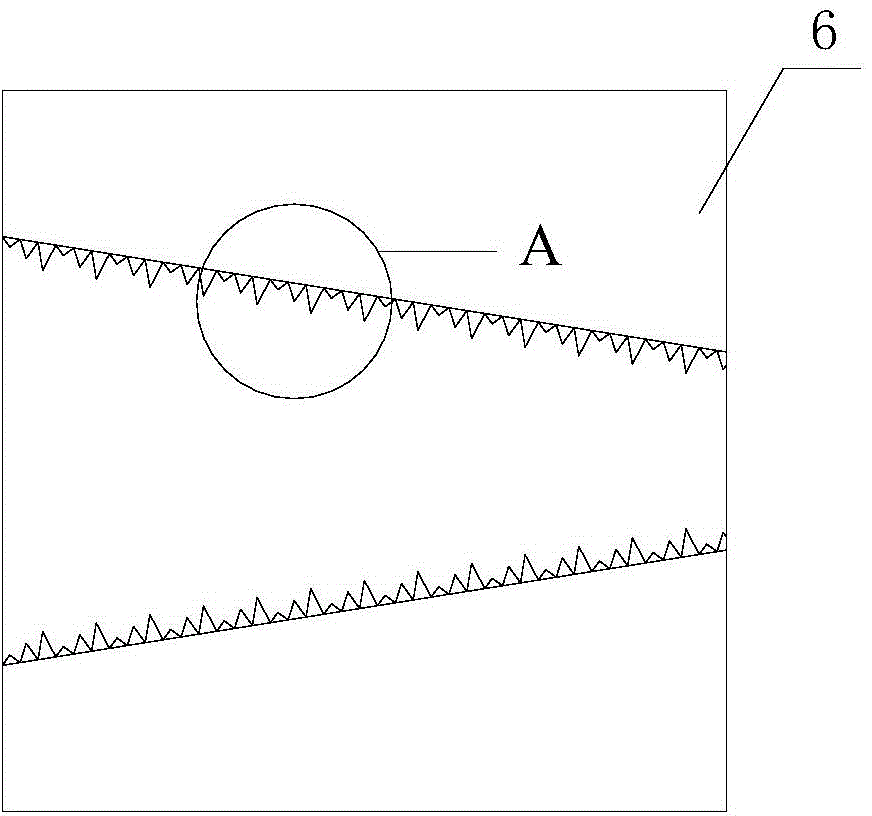

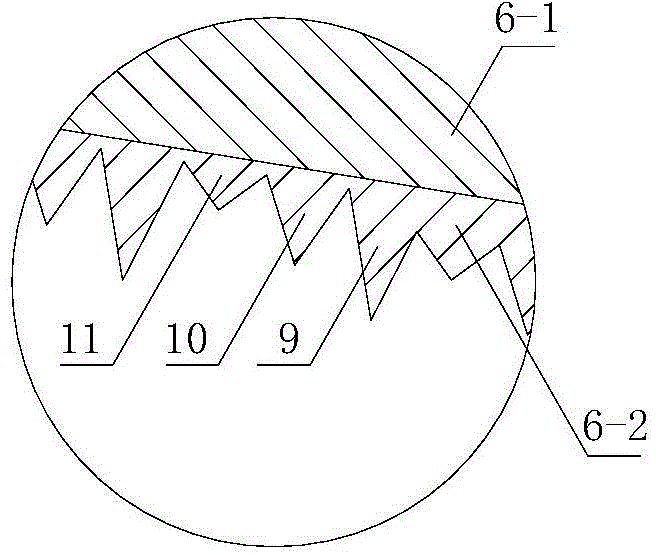

[0017] Such as figure 1 As shown, the simple micro-resistance and large-deformation anchoring device of the present invention is mainly composed of a pressure anchor 6, a guide spring 7 and a rooting anchor 8. The pressure anchor 6, the guide spring 7 and the rooting anchor 8 are arranged in sequence On the exposed section of the anchor cable 3, let the length of the compression anchor 6 be 1.5 to 2 times the length of the root anchor 8. The length of the anchor cable outside the root anchor 8 is L 1 Is 6~10cm, the length of the anchor cable between the anchor 6 and the root anchor 8 is L 2 Is 20 to 30 cm; the pressure letting anchor 6 includes an inner cone sleeve 6-1 with an inner cone hole, a clip 6-2 wedged with the inner cone sleeve 6-1, and the clip 6 2 There are 2 to 4 tooth-shaped letting threads with different diameters. The pitch of each tooth-li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com