Filling bag supporting mechanism

A technology for bag support and filling, which is applied in the field of filling bag support mechanism, can solve problems such as troubles, and achieve the effect of simple control mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. In the prior art, the acupuncture suction cup adopts the single bag taking mechanism of the automatic bag filling machine in the invention patent with application number 201620174609.5, which will not be described here.

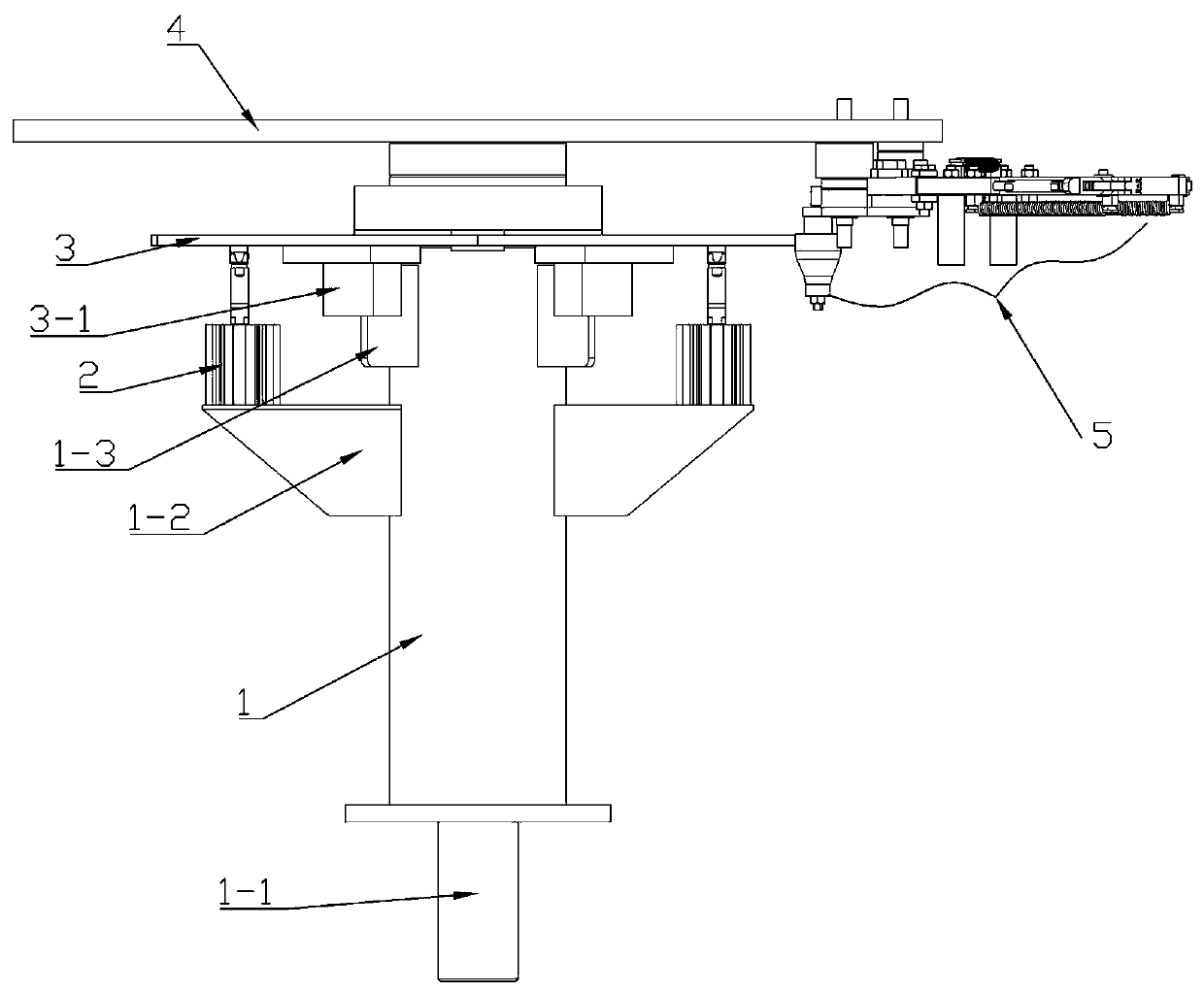

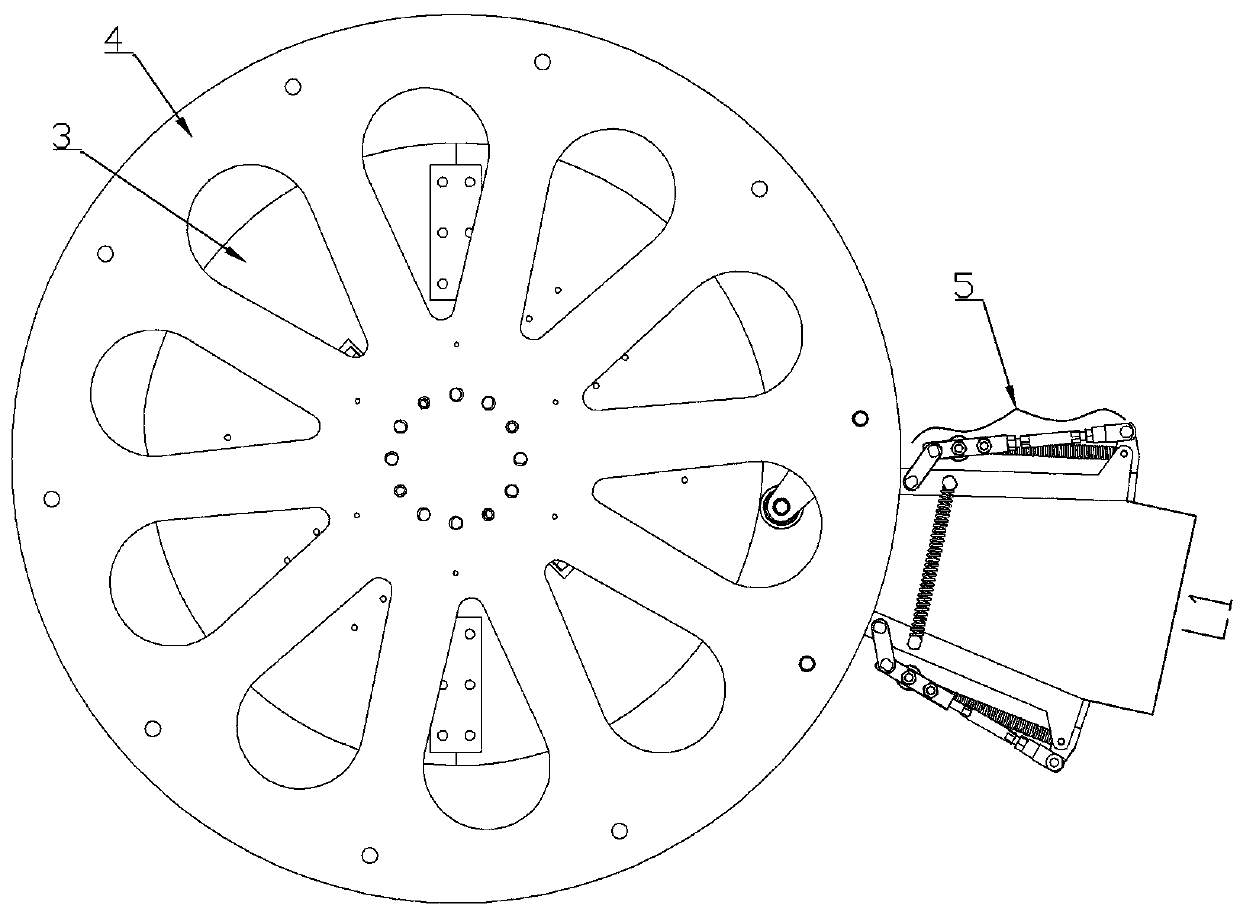

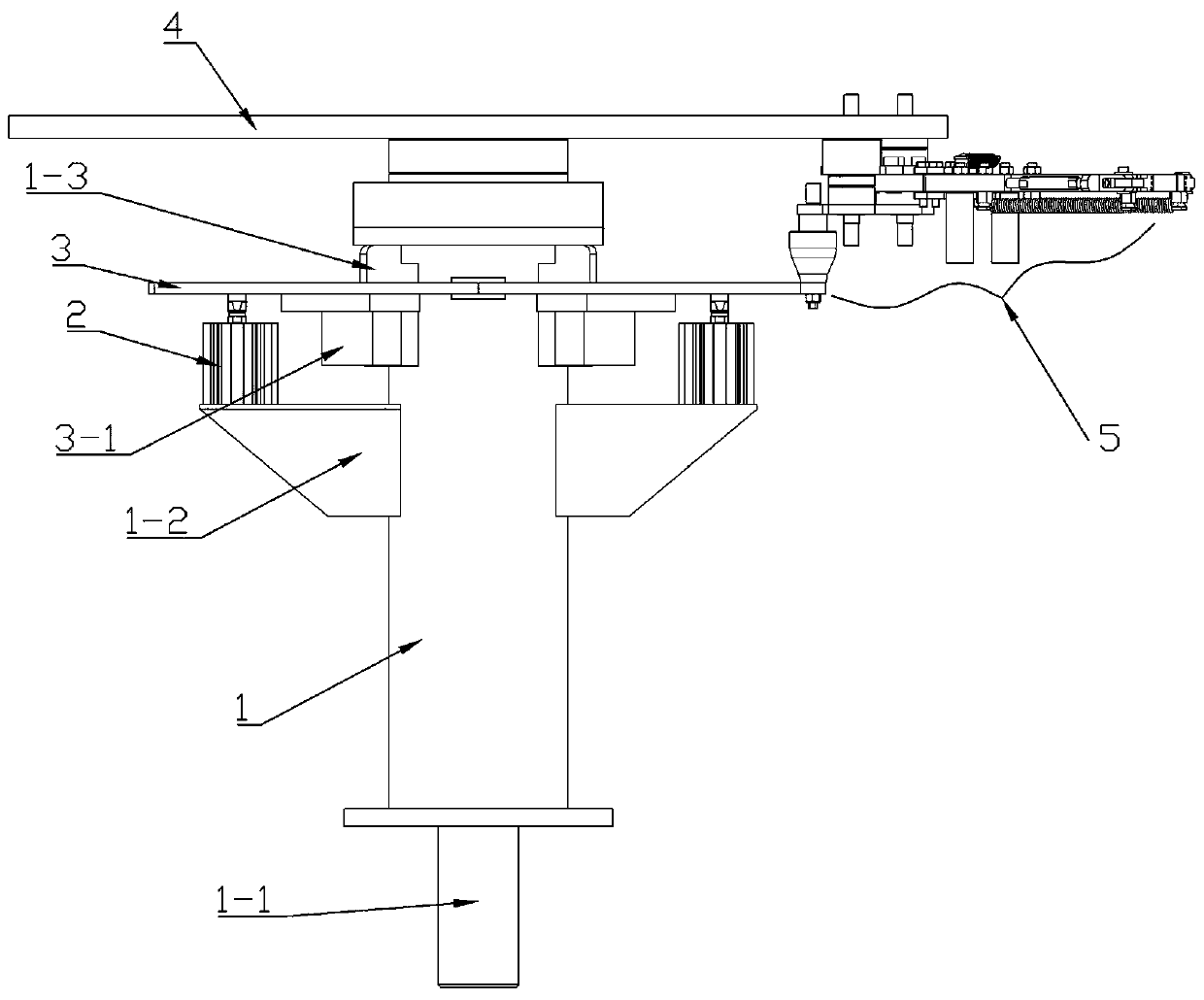

[0033] The specific embodiment of the present invention sees Figure 1-12 :

[0034] A filling bag support mechanism, such as Figure 1-7, including a bag support plate 3, a turntable 4 and a bag support arm 5, the bag support plate 3 is a circular plate installed on the central cylindrical column 1, and a rotating shaft 1-1 located in the center is fixed below the turntable 4 , the rotating shaft 1-1 passes through the cylindrical barrel downwards, the lower end of the rotating shaft 1-1 is connected to the drive motor and the reducer, the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com