Spring buffer pneumatic actuator

A pneumatic actuator and spring cushioning technology, which is applied in the direction of engine components, mechanical equipment, fluid pressure actuators, etc., can solve the position where the pneumatic control valve cannot meet the use requirements and does not allow the pneumatic control valve to violently hit, open and close Hysteresis and other problems, to achieve the effect of ingenious structure, small buffer stroke, and small installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific drawings and embodiments.

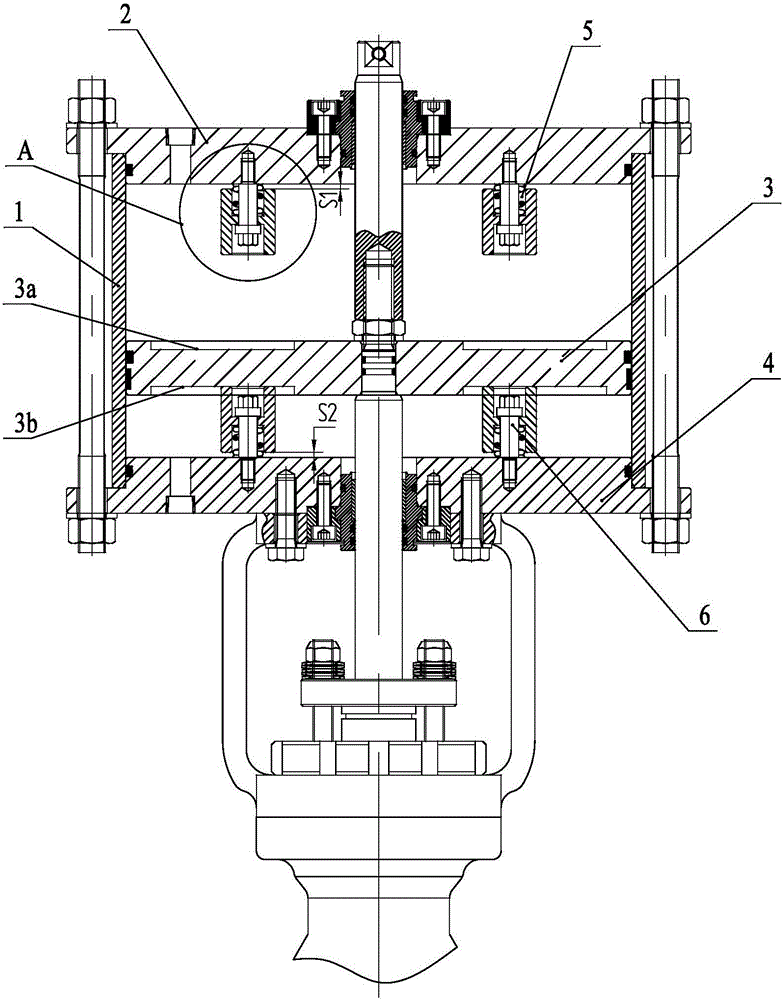

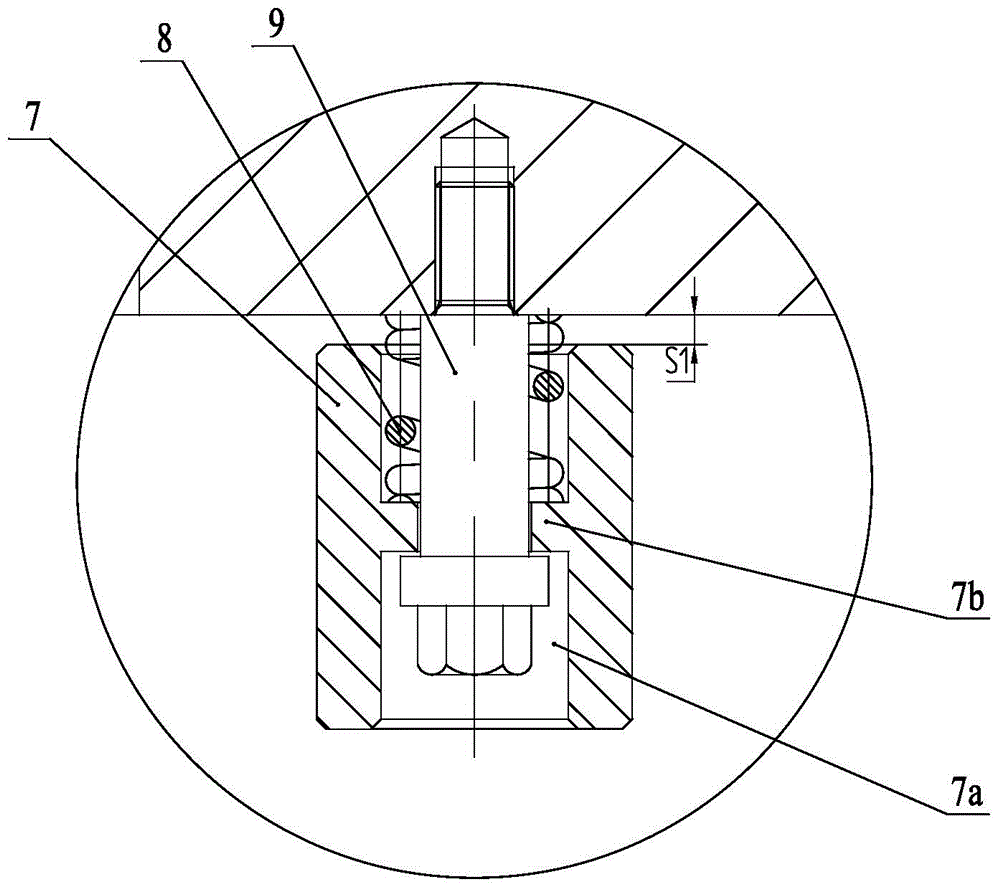

[0019] As shown in the figure: the spring-buffered pneumatic actuator in the embodiment is improved from the existing conventional piston-type pneumatic actuator. The piston-type pneumatic actuator mainly includes a cylinder body 1, an upper cylinder head 2, a lower cylinder Cover 3 and piston 4, the inner plane of the upper cylinder head 2 is provided with several upper spring buffer units 5 evenly distributed in the circumferential direction, and the upper spring buffer unit 5 cooperates with the upper surface of the piston 4 to provide the upward movement of the pneumatic actuator. Provide a buffering effect; the inner plane of the lower cylinder head 3 is provided with several lower spring buffer units 6 evenly distributed in the circumferential direction, and the lower spring buffer units 6 cooperate with the lower surface of the piston 4 to provide the dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com