Determination method of engine mounted pull rod tolerance value

A determination method and engine technology, applied in the aviation field, can solve the problems of low processing cost of system parts, and achieve the effect of simple implementation, solving long-term problems and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

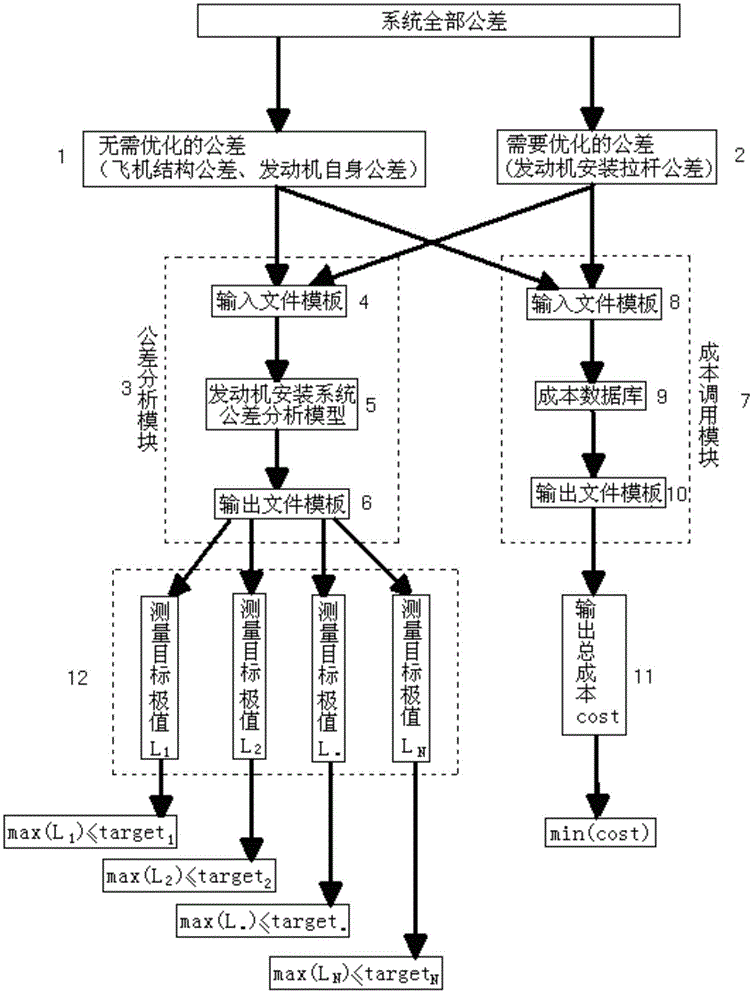

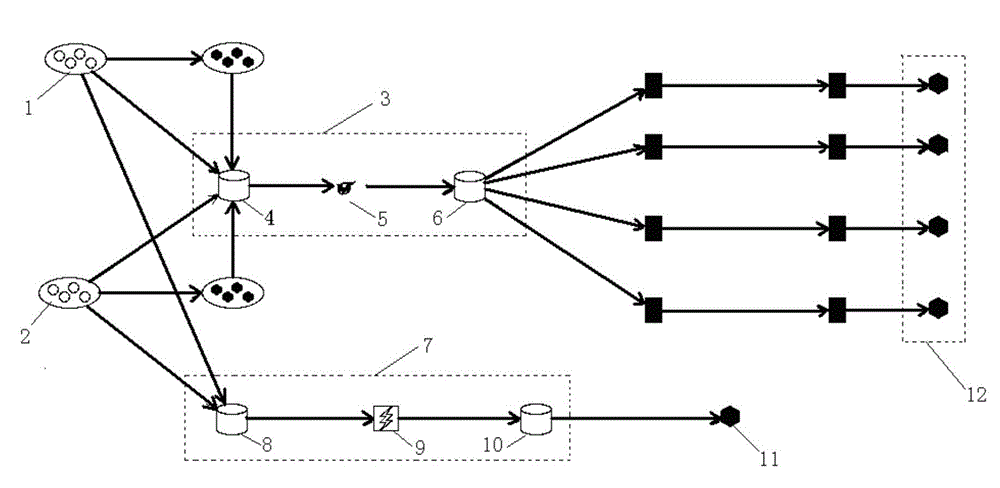

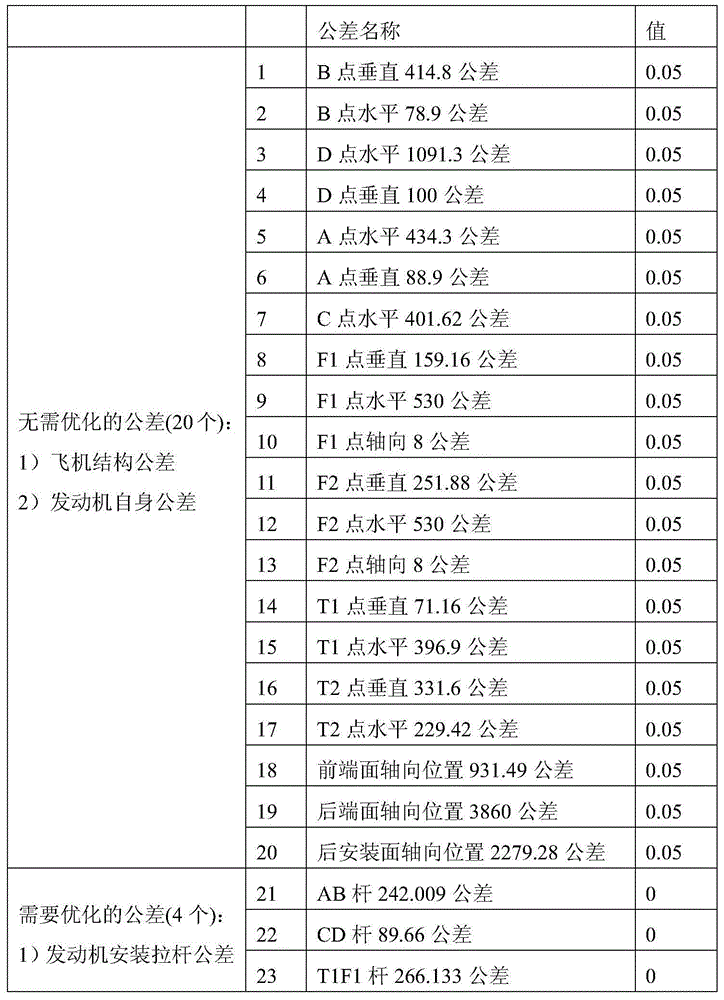

[0023] The following takes a certain type of aircraft engine installation system as an example, combining Table 1, Table 2, Table 3 and figure 2 , describe in detail the method of determining the tolerance value of the engine installation tie rod, the specific steps are as follows:

[0024] Step a: Divide all tolerances of the system into two categories: tolerance 1 that does not need optimization and tolerance 2 that requires optimization. Tolerance 1 that does not need optimization includes aircraft structure tolerances and engine tolerances; tolerance 2 that requires optimization includes tolerances for engine installation rods, In this example, it specifically refers to the four tie rod tolerances of the engine mounting system, including "AB rod 242.009 tolerance", "CD rod 89.66 tolerance", "T1F1 rod 266.133 tolerance", "T2F2 rod 311.075 tolerance", see Table 1.

[0025]

[0026]

[0027] Table 1

[0028] Step b: For a specific engine installation system, establish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com