Casing outer packer test device

A test device and packer technology, applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problems of ineffective separation and difficult operation, and achieve the effect of high reliability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

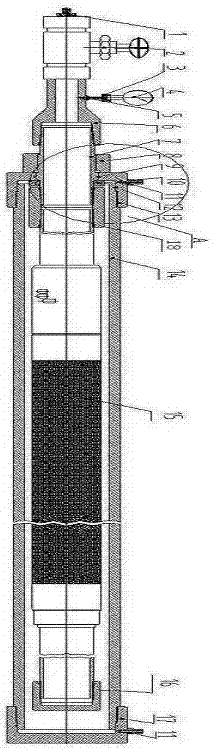

[0021] In order to overcome the problems of difficult operation and ineffective separation in the prior art, the present invention provides a method such as figure 1 , figure 2 The casing outer packer test device shown can effectively separate, ensure the normal construction, and can effectively complete the simulation test before the field application of the casing outer packer. Outer tubes serve their purpose in field applications.

[0022] Casing outer packer test device, including the test outer tube 14, the test outer tube 14 is a hollow pipe string, and the two ends of the test outer tube 14 are respectively fixedly connected with the fastening plug I13 and the fastening plug II17 through threads form a closed cavity;

[0023] A test piece outer casing packer 15 is arranged in the inner cavity of the test outer pipe 14, and the lower end of the casing outer packer 15 is sealed and connected by a plug 16 to form a closed space;

[0024] Both the fastening plug I13 and...

Embodiment 2

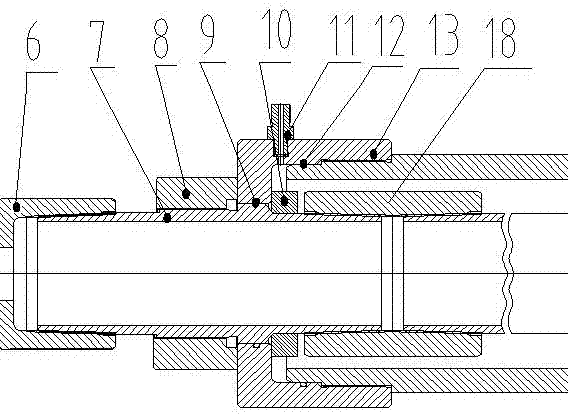

[0030] Based on the first embodiment, the pressure gauge 4 in this embodiment is arranged on the pressure gauge base 3 , and the pressure gauge base 3 is connected to the connector 6 through the pressure gauge connecting rod 5 .

[0031] A pressure gauge 4, a pressure gauge seat 3, and a pressure gauge connecting rod 5 are installed on the joint 6, which is convenient for observing the pressure value.

[0032] The test connecting pipe 7 is sealed and connected with the fastening plug I13 through the sealing ring 9 . The fastening plug II 17 is sealed and connected to the test outer tube 14 through the second sealing ring 12 .

[0033] A limit retaining ring 10 is provided at the outer diameter of the test outer tube 7, and the limit retaining ring 10 is located inside the fastening plug I13.

[0034] A needle valve 2 is arranged on the joint 1 .

[0035] The test connecting pipe 7 and the outer end surface of the fastening plug I13 are fixedly connected through the positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com