High-precision focusing mechanism for space optical remote sensor

A space optical remote sensing, high-precision technology, applied in the field of space remote sensing, can solve the problems of non-linear focusing amount, increase the difficulty of focusing control and assembly, complex mechanism, etc., and achieve small size, light weight and high focusing precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

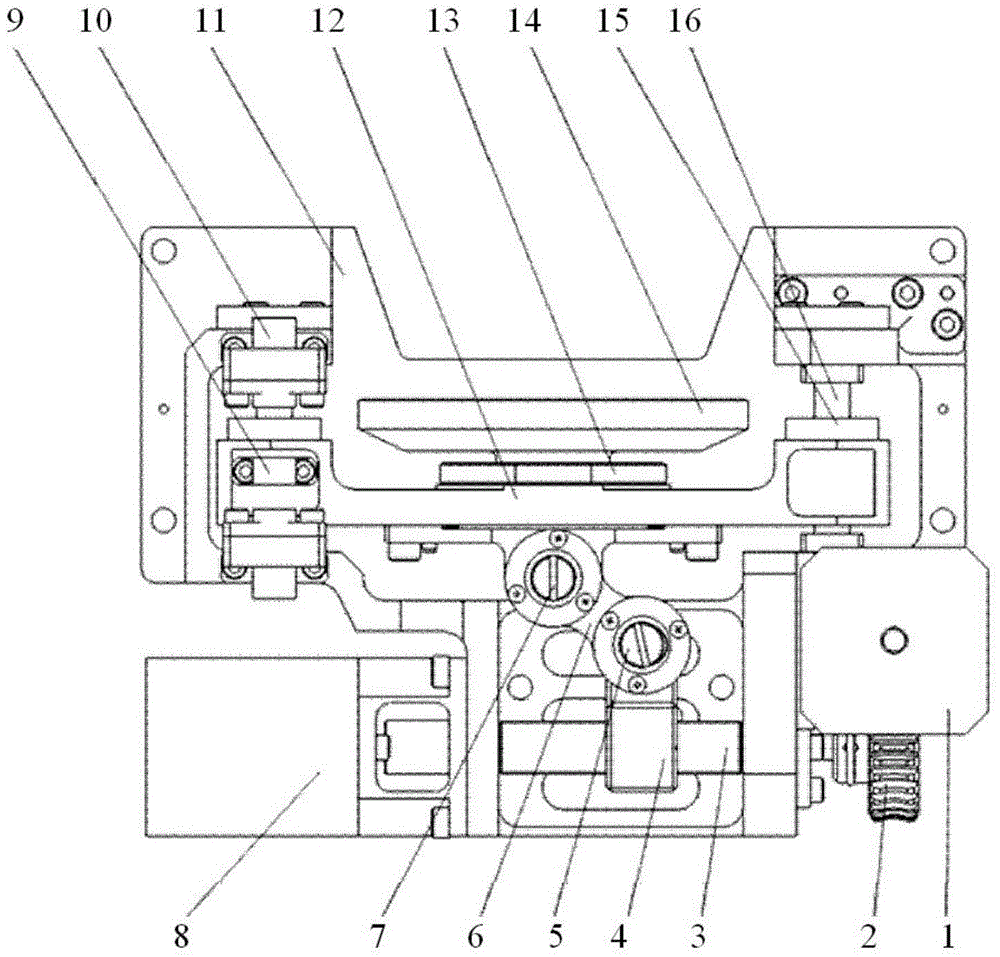

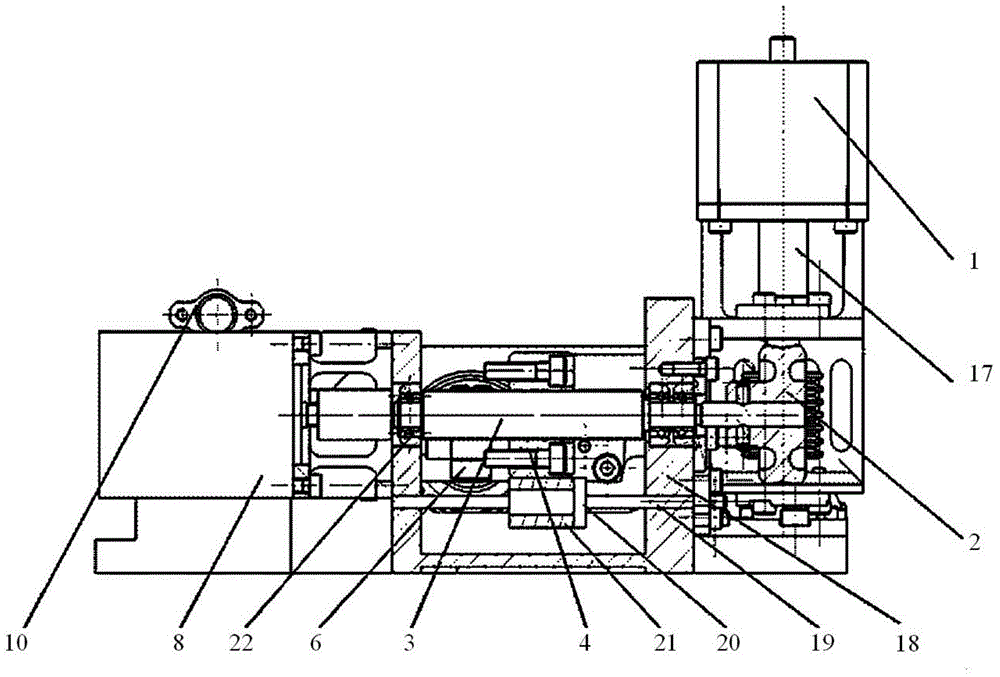

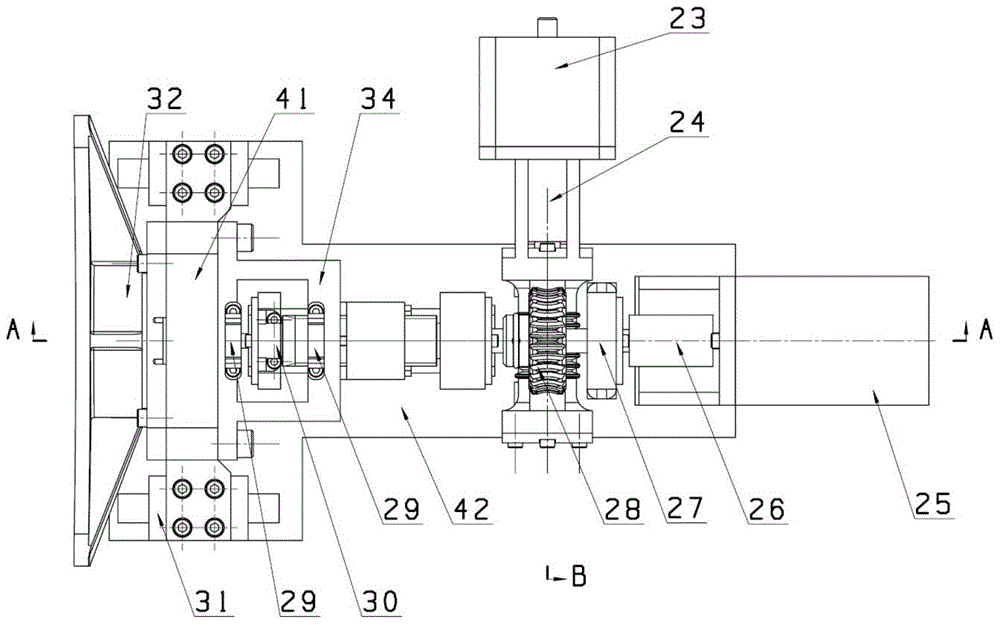

[0022] Such as Figure 3-5 As shown, the high-precision focusing mechanism applied to space optical remote sensors includes: a driving part and an execution part; wherein, the driving part includes: a motor 23, a first coupling 24, a first bearing 36-1 and a worm 37 The actuator includes: encoder 25, second coupling 26, bearing housing 27, second bearing 36-2, third bearing 36-3, worm wheel 28, Hall element 29, magnetic steel 30, lead screw 35, Special-shaped nut 34, screw 33, linear bearing seat 40, linear bearing 39, sliding shaft 38, adapter seat 41, focusing lens assembly 32, linear guide pair 31 and focusing base 42.

[0023] The output shaft of the motor 23 is fixedly connected to the input shaft of the worm 37 through the first coupling 24, and the two ends of the worm 37 are fixedly connected to the focusing base 42 through the first bearing 36-1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com