Body rotating device and mustard tuber harvester comprising same

A rotary device, harvester technology, applied in the direction of harvesters, agricultural machinery and implements, cutters, etc., can solve the problems of inconvenient turning and U-turn, easy to press mustard, affecting harvesting efficiency and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

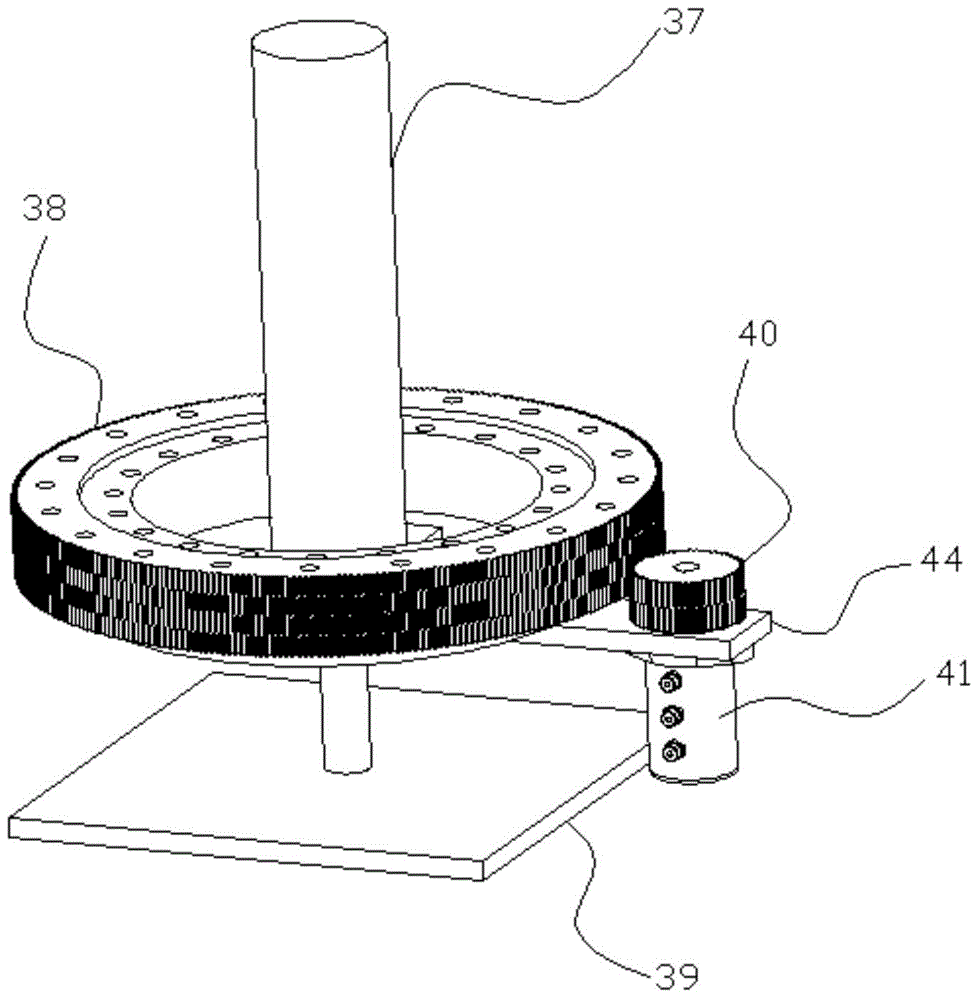

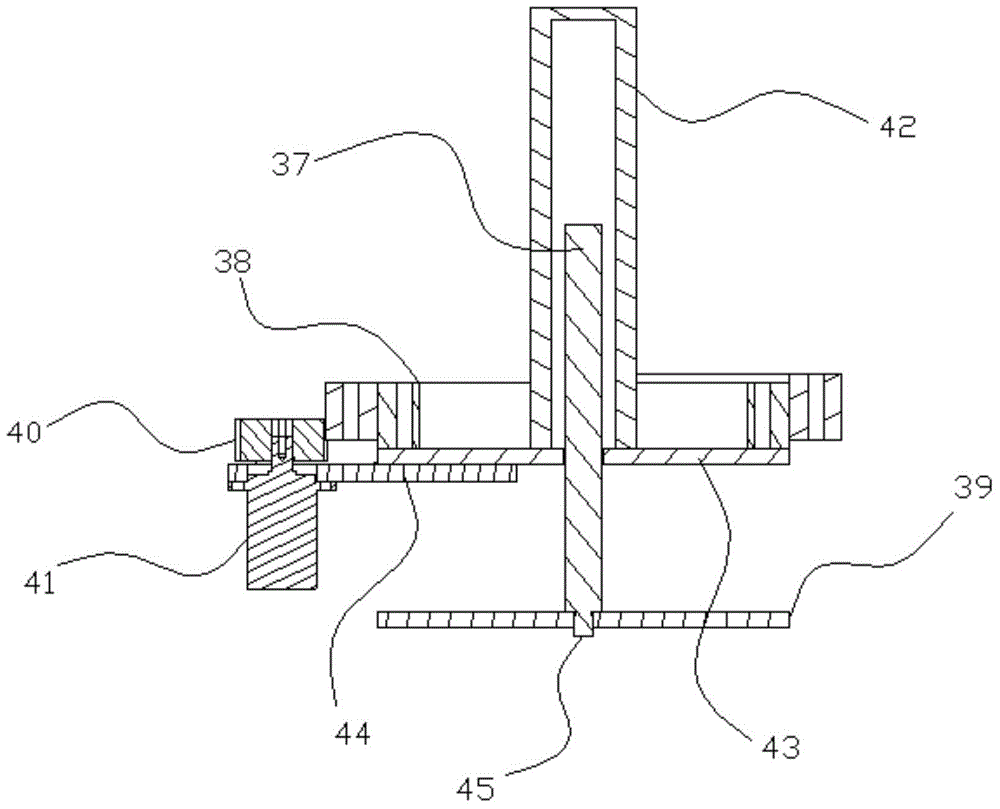

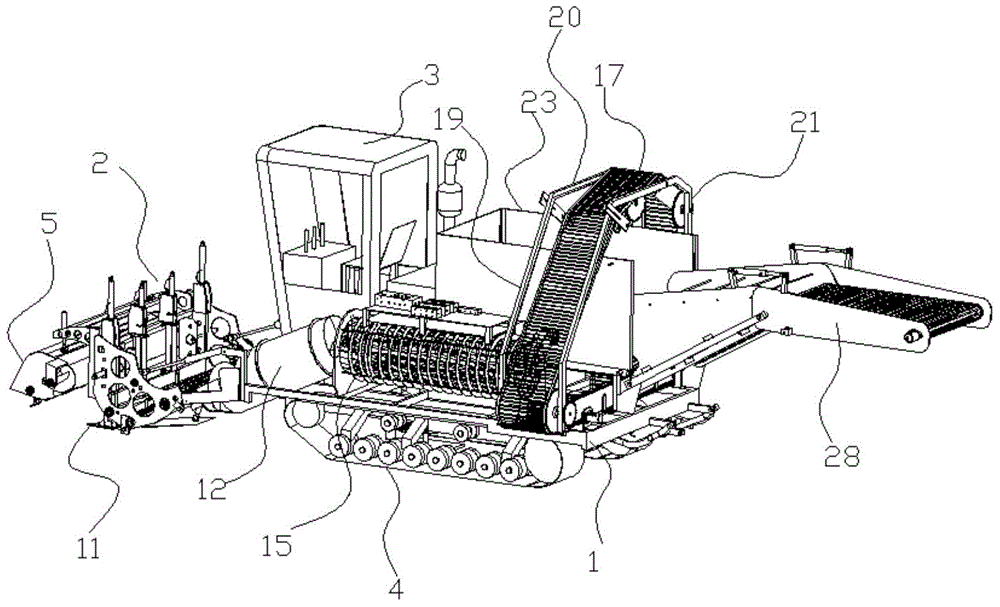

[0027] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 In the shown embodiment, a fuselage rotating device includes a top pressure oil cylinder 37 and a slewing bearing 38 connected with the main body. The top pressure oil cylinder is vertical with its cylinder body on the top and piston rod on the bottom. The piston rod of the oil cylinder is connected with a fuselage support plate 39 for contacting with the ground. The top pressure oil cylinder passes through the center of the slewing bearing and is coaxial with the slewing bearing. A slewing drive gear 40 is arranged beside the slewing bearing. A rotary power motor 41 is provided below the rotary drive gear, the output shaft of the rotary power motor is coaxial and connected to the rotary drive gear, and a circle of driven teeth is provided on the outer ring of the rotary bearing. The slewing bearing meshes with the slewing drive gear through the driven teeth.

[0028]...

Embodiment 2

[0035] Embodiment 2: the basic structure and implementation mode of this embodiment are the same as embodiment 1, and its difference is, as Figure 8 , Figure 9 , Figure 10 As shown, the fuselage is provided with a material distribution device, and the material distribution device includes a guide arc plate 30, a material distribution arc plate 31, an arc-shaped material distribution spring net 32, and a material distribution adjustment cylinder 33. The arc-shaped material distribution elastic net is connected on the material distribution arc plate, and the space between the material distribution arc plate and the arc-shaped material distribution elastic net is the screening part 34, and the described material distribution arc plate is attached to the guide arc On the board, the radian of the bottom surface of the material distribution arc plate matches the top surface curvature of the guide arc plate, and the piston rod of the material distribution adjustment cylinder is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com