Metal exterior surface automatic polishing machine

An automatic polishing and outer surface technology, which is applied in the direction of surface polishing machine tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of high cost, large force, deformation of parts to be processed, etc., and achieve low cost and not easy to compress The effect of loss and adjustment force is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

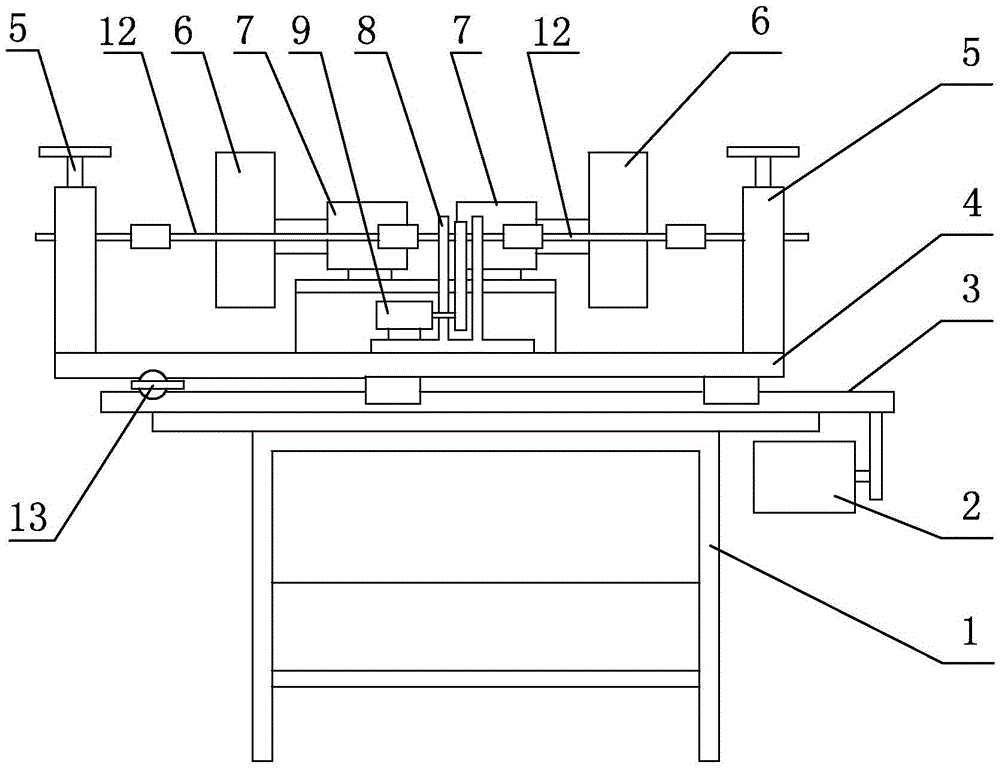

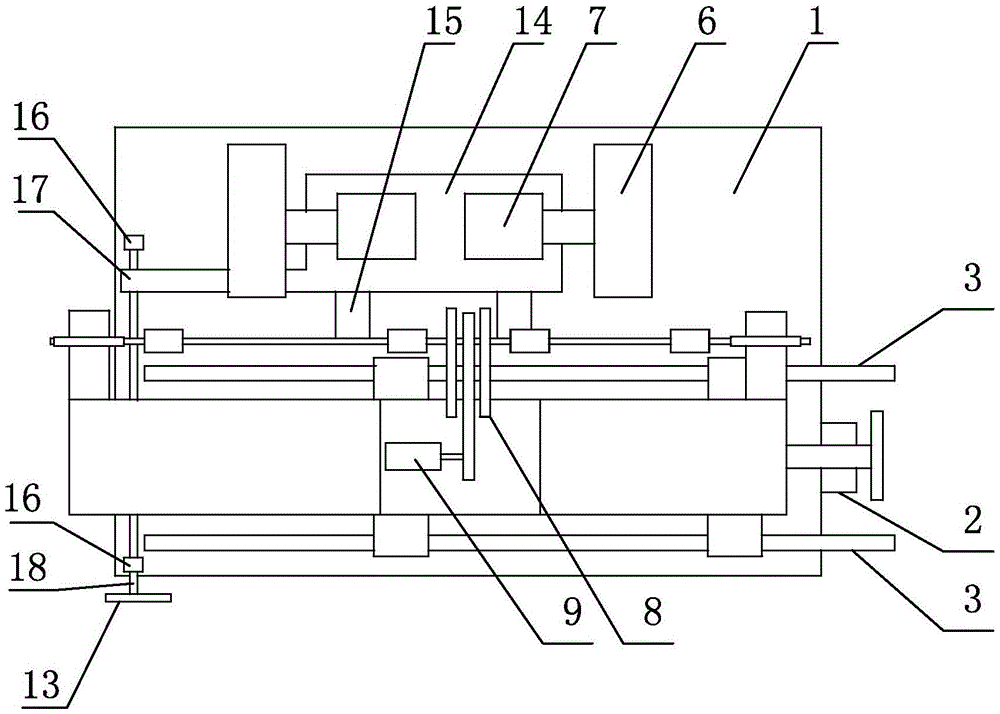

[0016] Embodiment: the metal outer surface automatic polishing machine of the present invention, as attached figure 1 , attached figure 2 As shown, it includes a base 1 with a platen, and the base 1 is provided with a polishing support 14 that can slide back and forth, and a fixed support 4 that can slide left and right.

[0017] One or two slide rails 3 are arranged between the base 1 and the fixed support 4 to form a sliding connection; the base 1 is provided with a reciprocating drive motor 2 that drives the fixed support 4 to reciprocate along the slide rail, and the reciprocating drive motor 2 and the fixed support A screw transmission mechanism is set between 4, the screw transmission mechanism can be a ball screw, and a chain drive or a belt drive or a gear drive transmission mechanism is set between the lead screw and the reciprocating drive motor 2.

[0018] A non-powered support 5 and a power support 8 are arranged on the fixed support 4, and the square steel 12 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com