Continuous tea twisting machine

A kneading machine and tea technology, which is applied in tea processing before extraction, etc., can solve problems such as low efficiency, large equipment body, and uneven quality of finished tea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

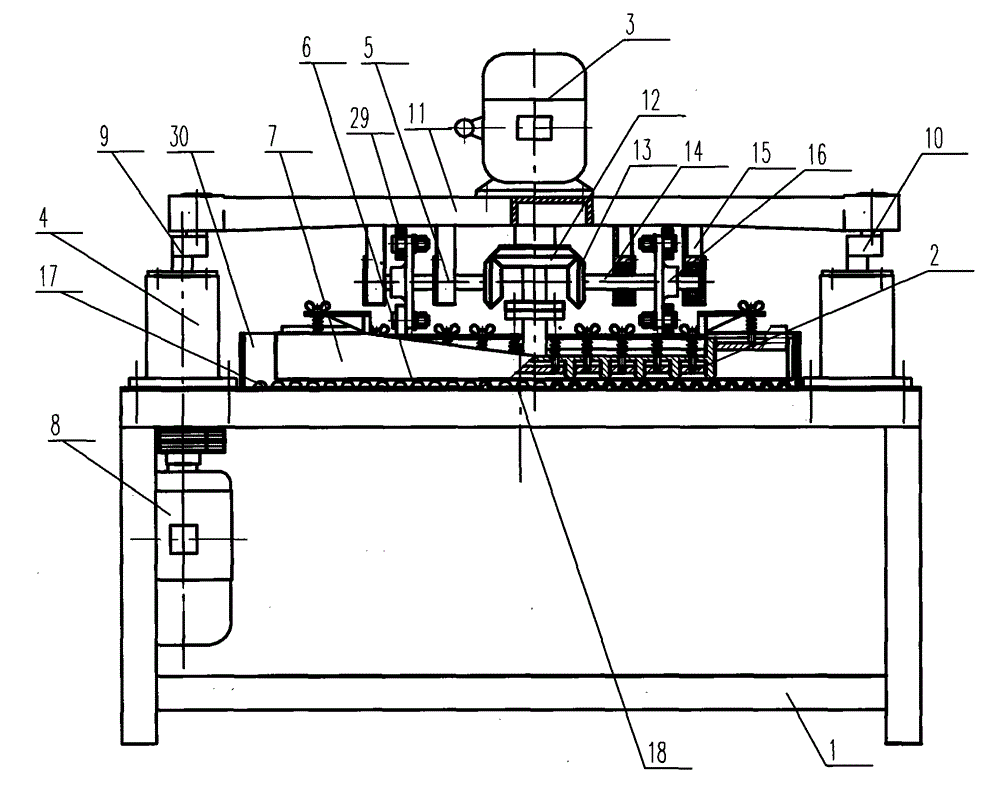

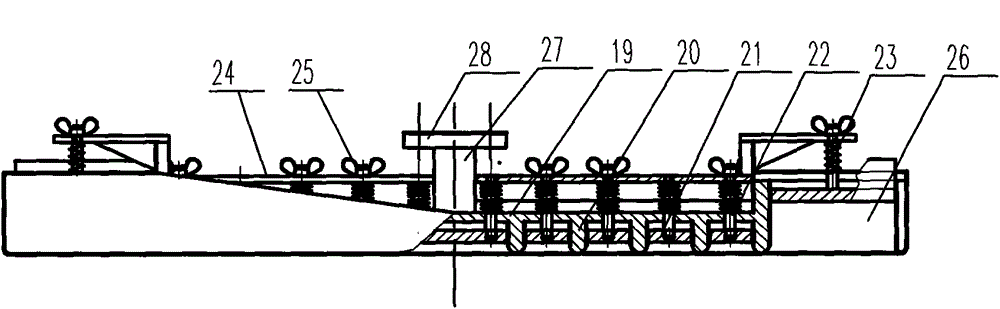

[0020] refer to figure 1 , a continuous rolling machine for tea, comprising a frame 1, a rolling device 2, a central motor 3, a parallelogram mechanism 4 and a pressing mechanism 5;

[0021] The kneading device 2 includes a kneading plate 6 and a kneading cover 7, and the kneading cover 7 is located above the kneading plate 6;

[0022] The parallelogram mechanism 4 includes: a transmission mechanism 8, a driving crankshaft 9, a driven crankshaft 10, and a motor frame 11;

[0023] The pressing mechanism 5 includes a large bevel gear 12, a small bevel gear 13, a small bevel gear shaft 14, a small bevel gear holder 15, and a presser 16;

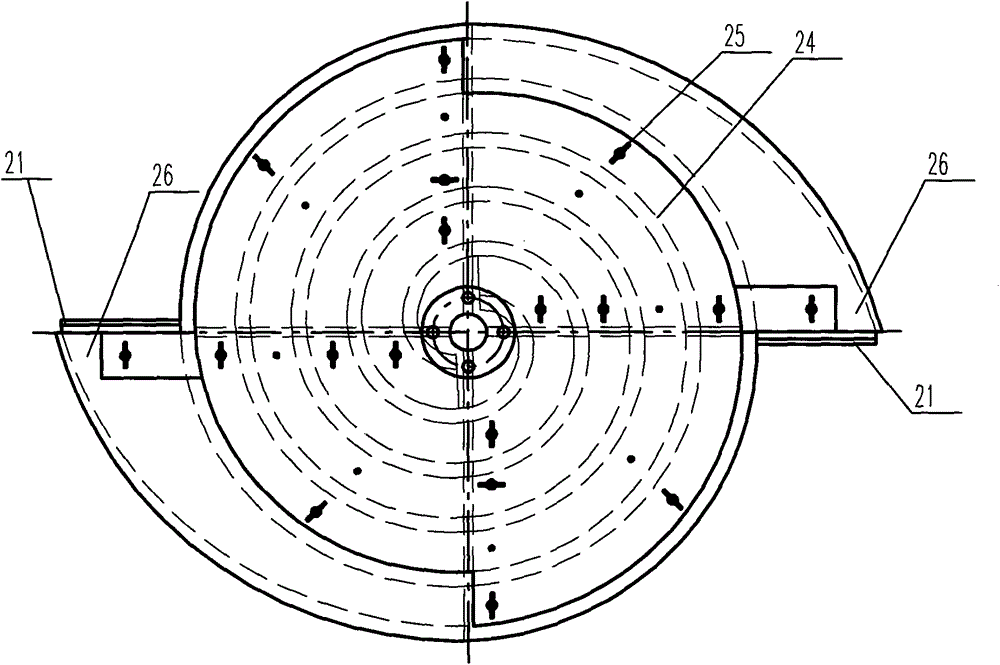

[0024] The kneading plate 6 is a flat plate, and the position on the flat plate that matches the operating range of the kneading cover 7 is provided with evenly distributed r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com