Continuous tea-twisting machine

A kneading machine and tea technology, applied in tea processing before extraction, etc., can solve the problems of high cultural quality requirements for operators, high cost, low efficiency, etc., achieve low cultural quality requirements, save energy and resources, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

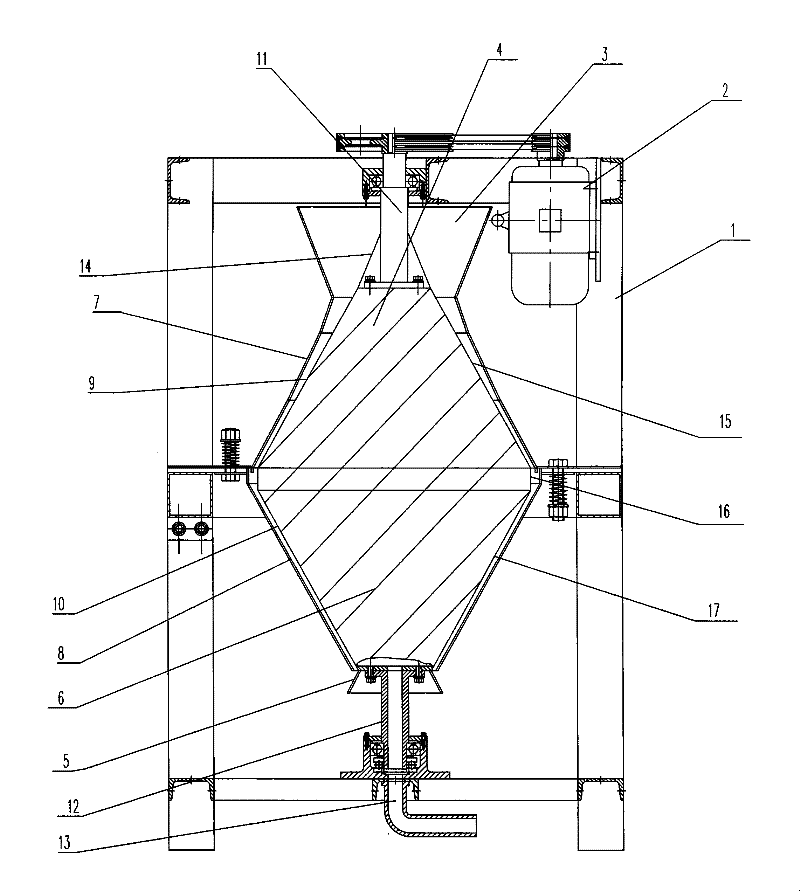

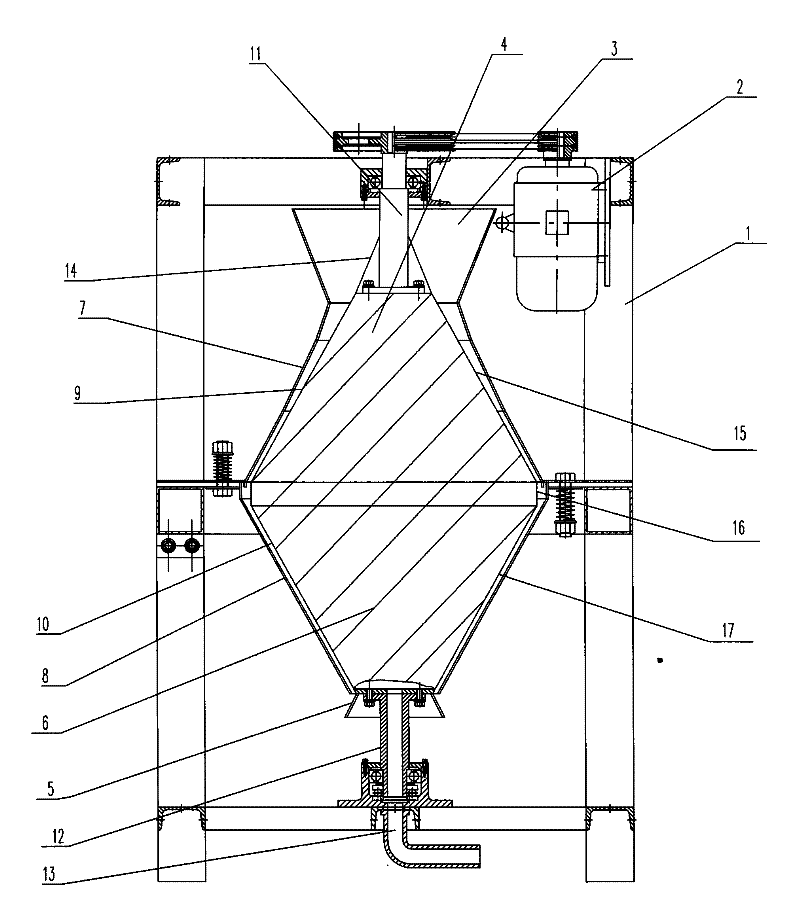

[0030] refer to figure 1 , a continuous rolling machine for tea, comprising a frame 1, a rolling device and a transmission mechanism 2, the rolling device includes a feed inlet 3, a kneading drum 4, a kneading cover and a discharge port 5, and the feeding inlet 3 is located at the kneading drum 4, the outlet is located below the kneading drum 4, and the kneading drum 4 is installed in the kneading cover;

[0031] The kneading drum 4 is formed by connecting the upper section 15 of the truncated cone shape and the lower section 17 of the inverted truncated cone shape. The kneading drum 4 is provided with a spiral guide vane tendon 6; Middle section 16.

[0032] The kneading cover is composed of an upper kneading cover 7 and a lower kneading cover 8. The upper kneading cover 7 and the upper section 15 of the k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com