Dust recovery device

A technology of dust recovery and collection port, which is applied in the field of powder devices, can solve problems such as troublesome use, unreasonable position setting, and inability to use continuously, so as to improve the collection effect, facilitate use, and ensure continuous use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

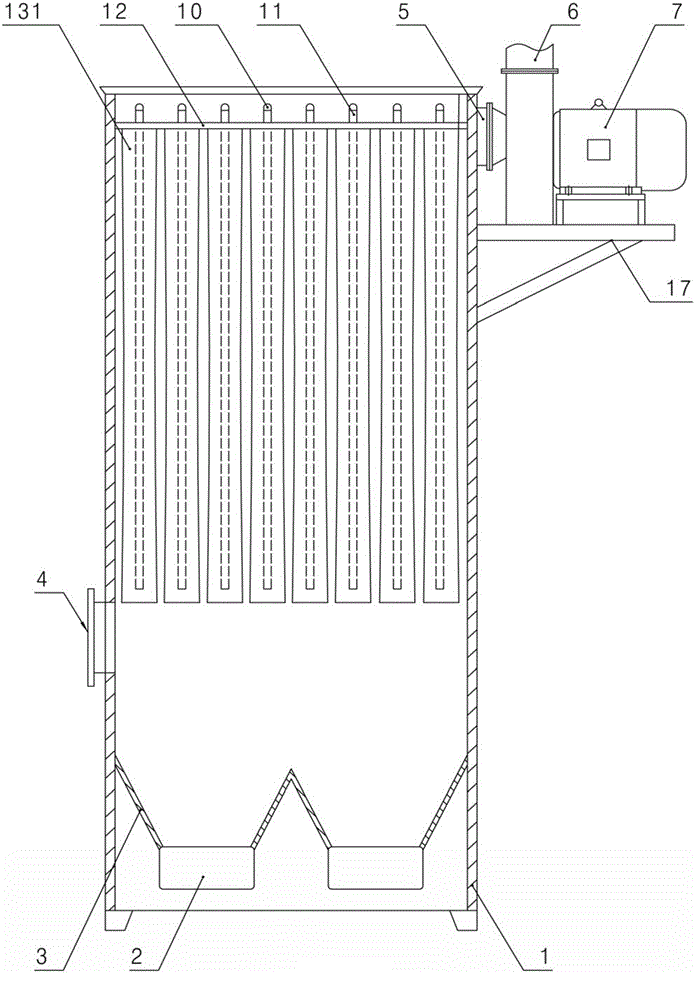

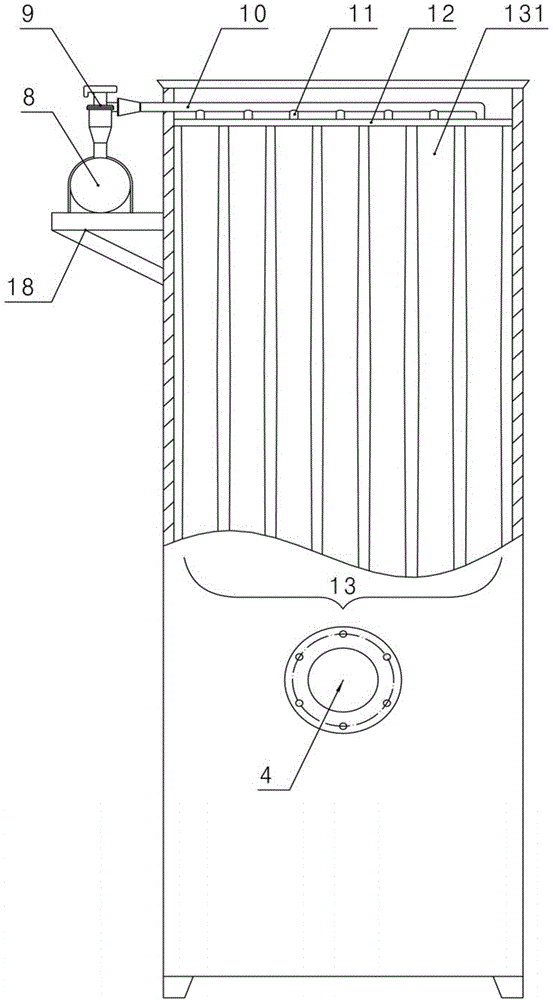

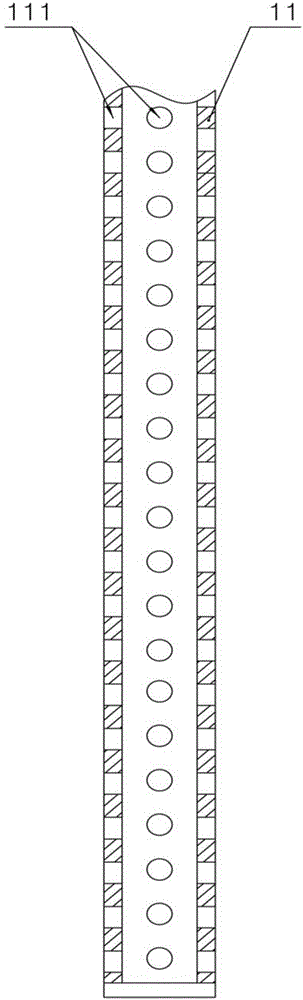

[0014] Such as figure 1 , figure 2 As shown, a dust recovery device according to the present invention includes: a housing 1, which is provided with a closed inner cavity, the lower part of one side of the housing 1 is provided with a collection port 4, and the upper part of the other side is provided with an air outlet , the casing 1 is provided with an exhaust fan 7 matched with the air outlet through the exhaust fan bracket 17, the inlet of the exhaust fan 7 communicates with the air outlet on the casing 1 through the air outlet pipe 5, and the upper part of the inner cavity of the casing 1 is provided with a horizontal The filter bag plate 12 arranged in the direction of the filter bag plate 12 is hoisted with several filter bag groups 13 along the direction from the collection port 4 to the air outlet (it can be determined according to the actual situation, 8 in the figure), and the same filter bag The filter bags 131 of group 13 are arranged in a straight line, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com