Stamping die

A stamping die and die base technology, applied in the field of molds, can solve problems such as warping and deformation, easy product appearance, and low product yield, and achieve the effects of reducing bending springback, avoiding warping deformation, and improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

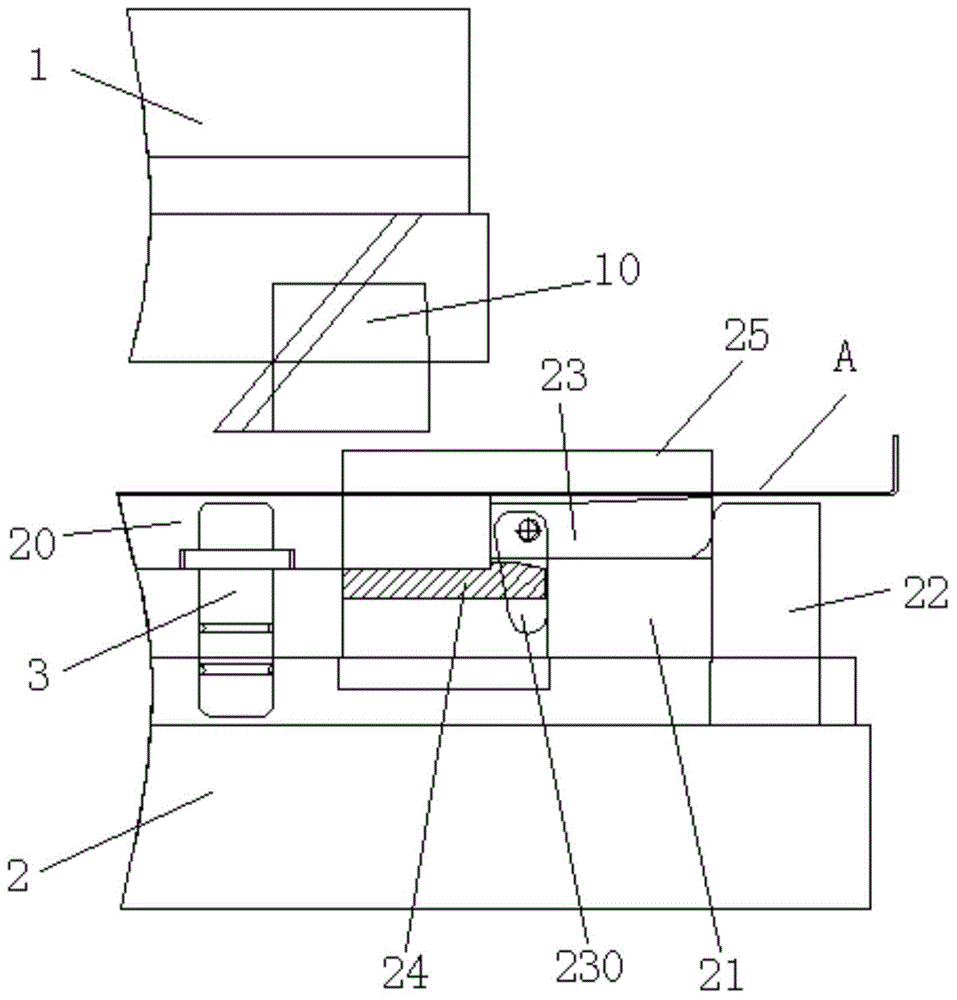

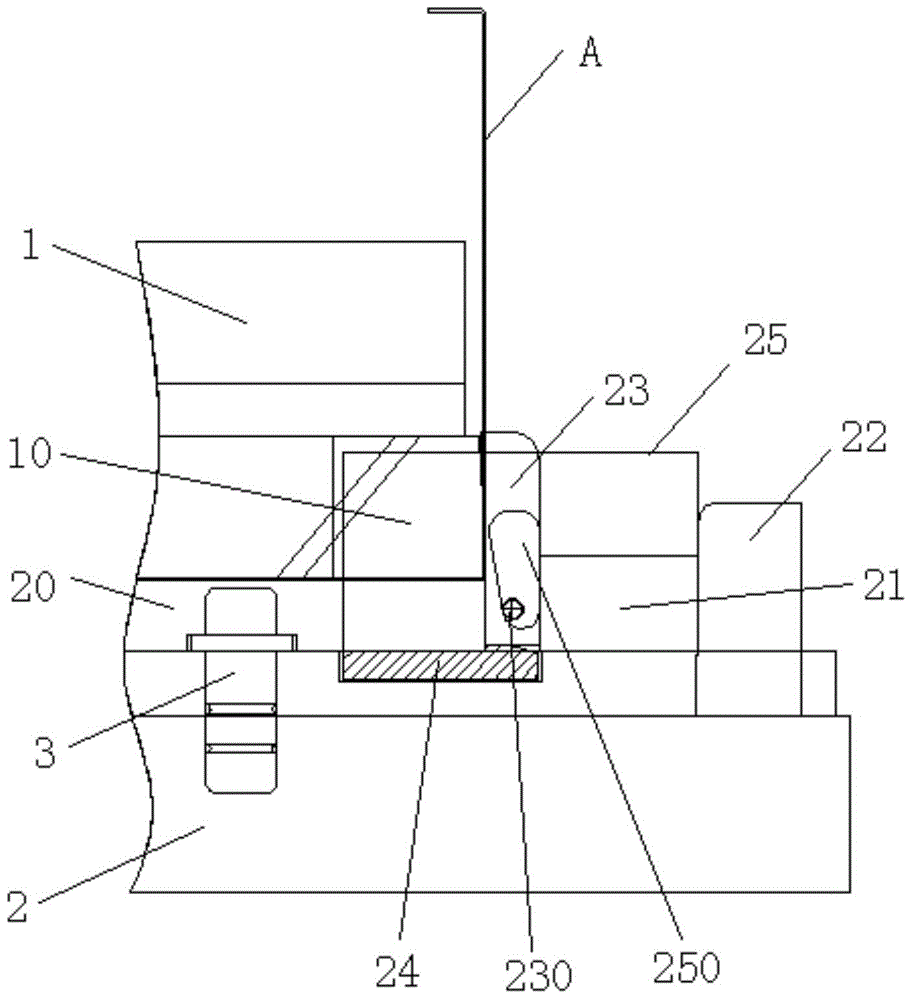

[0022] Preferred embodiments of the present invention will be described in detail below with reference to the drawings.

[0023] A stamping die according to the present invention includes an upper mold base 1 and a lower mold base 2 arranged up and down, the upper mold base 1 can perform mold opening and closing movement relative to the lower mold base 2, and the upper mold base 1 A lower stripping plate 20 is arranged between the base 1 and the lower mold base 2, and the lower stripping plate 20 can move downward relative to the lower mold base 2 by the movement of the upper mold base 1, and at the same time, the lower stripping plate 20 A reset mechanism capable of driving the lower stripping plate 20 to reset is also provided between the plate 20 and the lower mold base 2; Positioning is provided with a first block 21 and a second block 22, and the upper side of the first block 21 is freely provided with a warping plate 23 that cooperates with the lower stripping plate 20 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com