Polishing structure for old sand regeneration

A technology for regenerating and grinding old sand, which is applied in the field of used sand processing equipment, can solve the problems of poor regeneration effect and high energy consumption, and achieve the effect of reducing energy consumption, low energy consumption and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

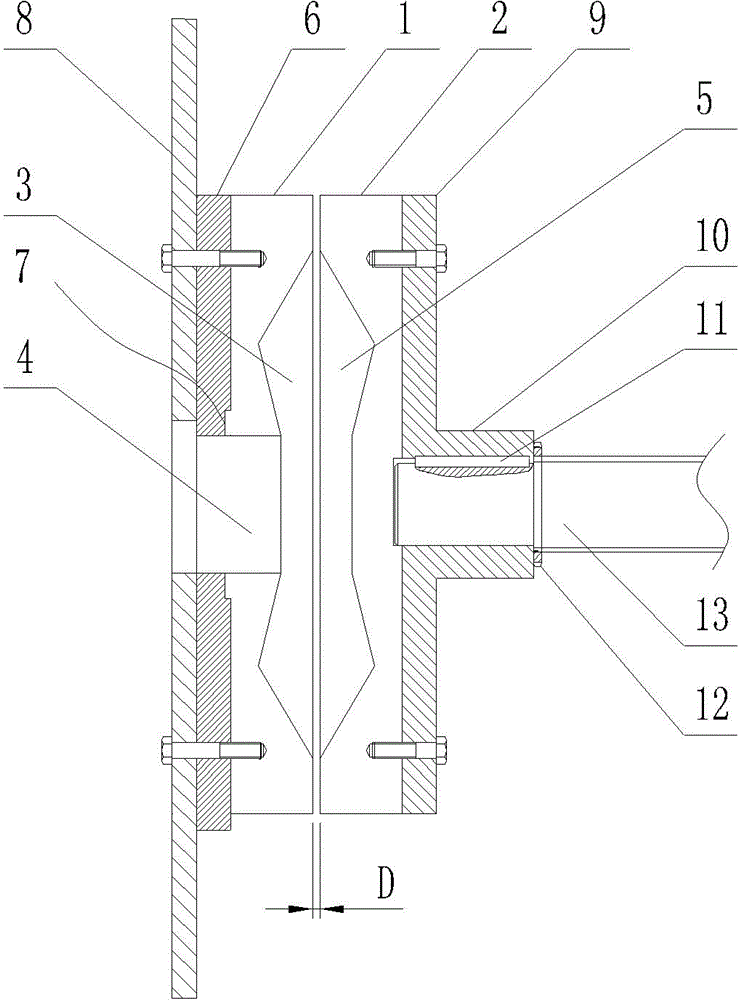

[0011] like figure 1 As shown, the frosting structure of old sand regeneration includes a fixed grinding disc 1 and a moving grinding disc 2, the moving grinding disc 2 is fixed on the connecting disc 9 by bolts, the shaft sleeve part 10 in the center of the connecting disc 9 and the driving device of the old sand recycling machine The output shaft 13 is keyed and locked by a nut 12. 11 in the figure is a flat key. The fixed grinding disc 1 is fixed on the inner wall of the shell of the used sand recycling machine. There is also a mounting plate 6 between the fixed grinding disc 1 and the shell. , the housing, the mounting plate 6 and the fixed millstone 1 are fixedly connected by bolts, the fixed millstone 1 and the movable millstone 2 are arranged in parallel, and the opposite end faces of the fixed millstone 1 and the movable millstone 2 are respectively provided with a sand storage tank 1 3 and a sand storage tank 2 5 , the fixed grinding table 1 is also provided with a sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com