Construction method of large reinforced concrete prefabricated column and beam lifting auxiliary embedded part

A technology of reinforced concrete and construction method, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of high cost and long construction period, and achieve the effect of reducing construction cost, shortening construction period and overcoming long construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

[0035] The large-scale reinforced concrete prefabricated column and beam hoisting auxiliary embedded parts construction method of the present invention comprises the following steps:

[0036] a. Design of embedded iron parts, including the following steps:

[0037] (1) Calculate the basic data of prefabricated reinforced concrete prefabricated columns and beam loads;

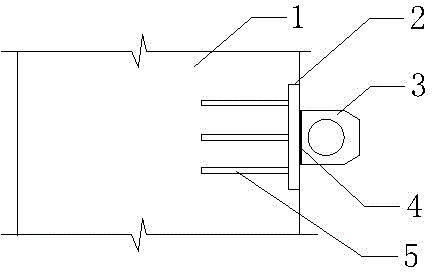

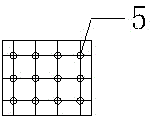

[0038] (2) Determine the specifications, models, and layout of the anchor bars of the embedded iron parts, as well as the connection method between the anchor bars and the embedded steel plates;

[0039] (3) Determine the specification and size of the embedded steel plate;

[0040] (4) Determine the specification, size, geometric shape and connection method of the hoisting lug steel plate and the embedded steel plate;

[0041] b. The construction of embedded iron parts includes the following...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com