Ball mill sliding shoe abrasion repairing method

A technology of wear repair and ball mill, applied in the direction of grain processing, etc., can solve the problems of high cost and long construction period, and achieve the effects of reducing economic loss, reducing vibration, avoiding thermal deformation and thermal stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

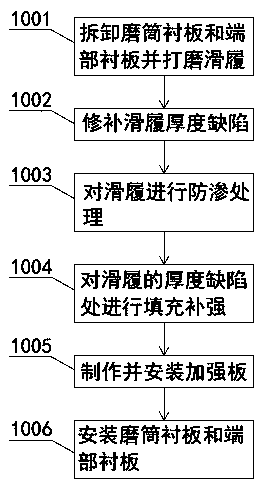

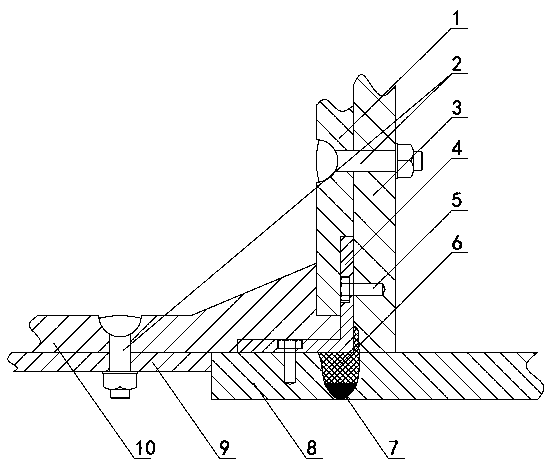

[0026] Figure 1~2 It is the best embodiment of the present invention, below in conjunction with the attached Figure 1~2 The present invention will be further described.

[0027] Such as figure 2 As shown, the sliding shoe 8 is arranged at the end of the grinding cylinder wall 9, and the grinding cylinder liner 10 is fixed on the inner wall of the grinding cylinder wall 9 through the lining plate fixing bolt 2, and the inner wall of the web 3 at the end of the grinding cylinder is also fixed. The end liner 1 is fixed by the liner fixing bolt 2, such as figure 1 As shown, a method for repairing sliding shoe wear of a ball mill comprises the following steps:

[0028] Step 1001, disassembling the grinding cylinder liner 10 and the end liner 1 and grinding the sliding shoe 8;

[0029] Remove the grinding cylinder liner 10 and the end liner 1 in the grinding cylinder, clean the inner and outer surfaces of the sliding shoes 8 to be repaired, and remove defects such as corners,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com