Material pallet

A pallet and material technology, applied in the field of material pallets, can solve the problems that the size of the pallet cannot be reduced or extended, time-consuming and labor-consuming, complicated assembly, etc., and achieve the effect of convenient assembly, increased bearing area, and stable bearing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

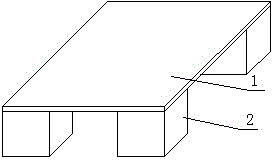

[0037] A material pallet, including a carrying unit 1 and a support unit 2, such as figure 1 , figure 2 , The bearing unit 1 includes a bearing panel 11, the bottom of the bearing panel 11 is provided with a number of support units 2, the support unit 2 includes a support frame 21 and an outer support frame 22, the support frame 21 and the outer support frame 22 are sleeved, The support frame 21 adopts an internal hollow structure, and the support frame 21 is completely embedded in the outer support frame 22; the bearing panel 11 and the support frame 21 connected to the bottom of the bearing panel 11 are integrally formed.

[0038] By embedding the support frame 21 in the outer support frame 22, the tray can be installed and the assembly is convenient. The load-bearing panel 11 and the support frame 21 connected to the bottom of the load-bearing panel 11 are integrally formed, which can reduce the production process and reduce the cost, while making the connection between the lo...

Embodiment 2

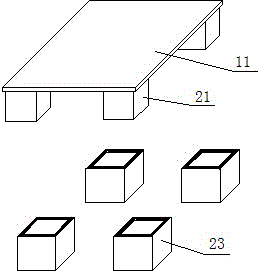

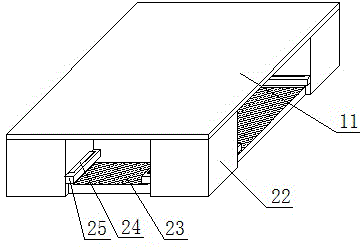

[0041] The structure of the second embodiment is basically the same as that of the first embodiment, and the difference between the second embodiment and the first embodiment is that: the support unit 2 further includes a connecting plate 23, such as image 3 , The two ends of the connecting plate 23 are respectively provided with flanges 24, the flange 24 and the connecting plate 23 are arranged perpendicularly, the side of the outer support frame 22 is provided with a card slot 25 through which the flange 24 passes, and the support unit 2 passes through the connecting plate 23 Connect adjacent outer support frames 22. The connecting plate 23 can realize the connection to the support frame 21 or the outer support frame 22, such as a square shape, a straight shape, etc., such as Figure 8 , Picture 9 . When the connecting plate 23 is connected to the card slot on the proximal side of the outer support frame 22, the distance between the outer support frames 22 can be increased; ...

Embodiment 3

[0044] A material tray includes a carrying unit 1 and a support unit 2. The carrying unit 1 is formed by splicing two or more carrying panels 11, such as Figure 4 , The bottom of the load-bearing panel 11 is provided with a number of support units 2, which include a support frame 21 and an outer support frame 22, the support frame 21 and the outer support frame 22 are sleeved, and the support frame 21 adopts an internal solid structure , The support frame 21 is completely embedded in the outer support frame 22; the bearing panel 11 and the support frame 21 connected to the bottom of the bearing panel 11 are integrally formed. The support frame 21 includes a corner support frame 211, a side support frame 212 and a center support frame 213.

[0045] The supporting frame 21 is set at the end of the supporting panel 11, and the corresponding supporting frame 21 at the splicing position of the supporting panel 11 is embedded in the same outer supporting frame 22, such as Figure 5 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com