Transmission vibration reducing structure of crane lifter

A lift, crane technology, applied in the direction of lifting frame, lifting device, etc., can solve the problem that the shock absorption treatment is not very ideal, and achieve the effects of good shock absorption effect, strong practicability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

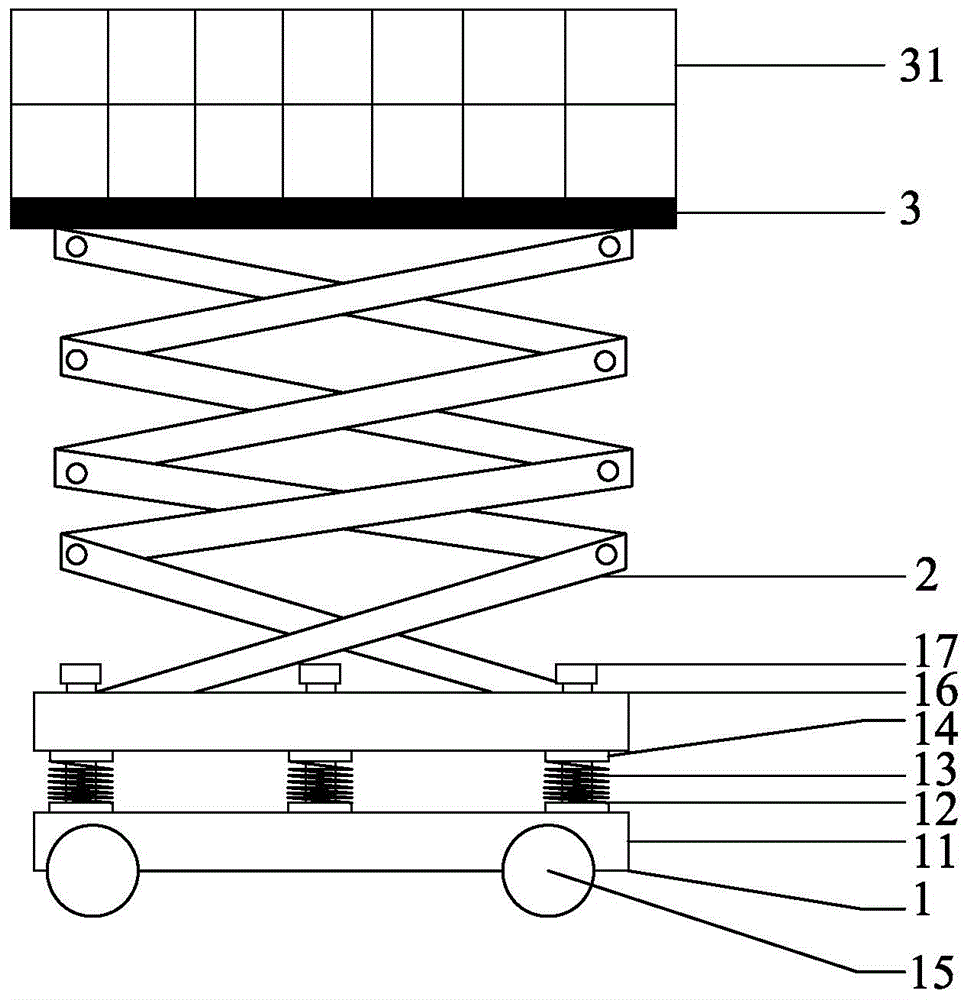

[0017] Such as figure 1 As shown, a crane lifter transmission shock absorbing structure includes a lifter main body 1, a double-folding lifting frame 2 fixed on the lifting frame 1 and a support platform 3 fixed on the upper end of the lifting frame 2, and the lifting frame The main body 1 is provided with rolling wheels 15, and the lifter main body 1 includes a hydraulic cylinder for providing a power source, a first bottom plate 11 and a second bottom plate 16, and between the first bottom plate 11 and the second bottom plate 16 A plurality of shock absorbing devices, the shock absorbing device includes a first washer 12, a shock absorbing spring 13 and a second washer 14 arranged in sequence, and the first bottom plate 11 and the second bottom plate 16 pass through the bolts 17. The shock absorbers are held together.

[0018] The bolt 17 is provided with an adjustment clearance for adjusting the damping strength of the damping device.

[0019] A protective net 31 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com