Automatic capping machine for plastic cans

A technology of plastic caps and capping machines, which is applied in the direction of capping containers tightly with caps, flanged bottle caps, and conveyor objects. Damage and other problems, to achieve the effect of stable damage, reduced floor space, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

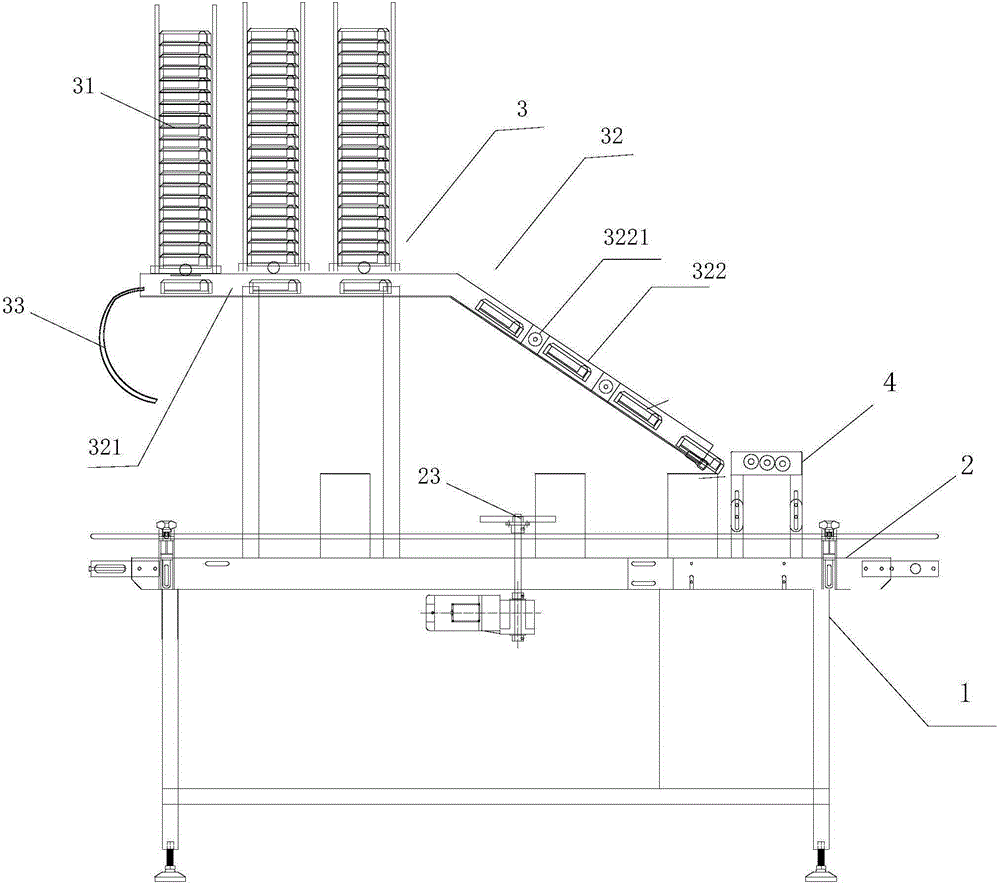

[0026] Such as Figure 1 to Figure 5 Shown: an automatic capping machine for plastic caps, characterized in that it includes a stand 1,

[0027] The platform 1 is provided with a conveyor belt mechanism 2 for transporting plastic tanks that need to be capped;

[0028] A plastic cover lower cover mechanism 3 is provided above the conveyor belt mechanism 2 for conveying plastic covers;

[0029] A roller capping mechanism 4 is provided at the intersection of the conveyor belt mechanism 2 and the plastic cap lower mechanism 3 for pressing the plastic cap tightly on the plastic tank;

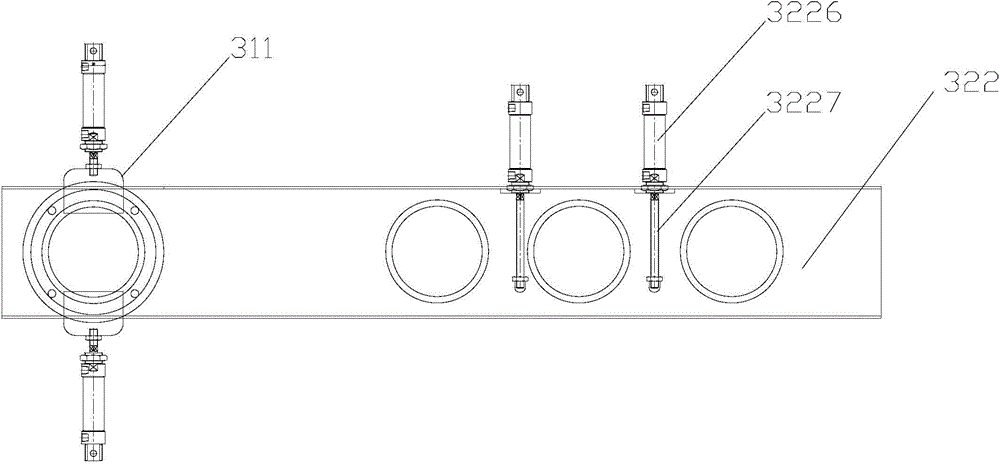

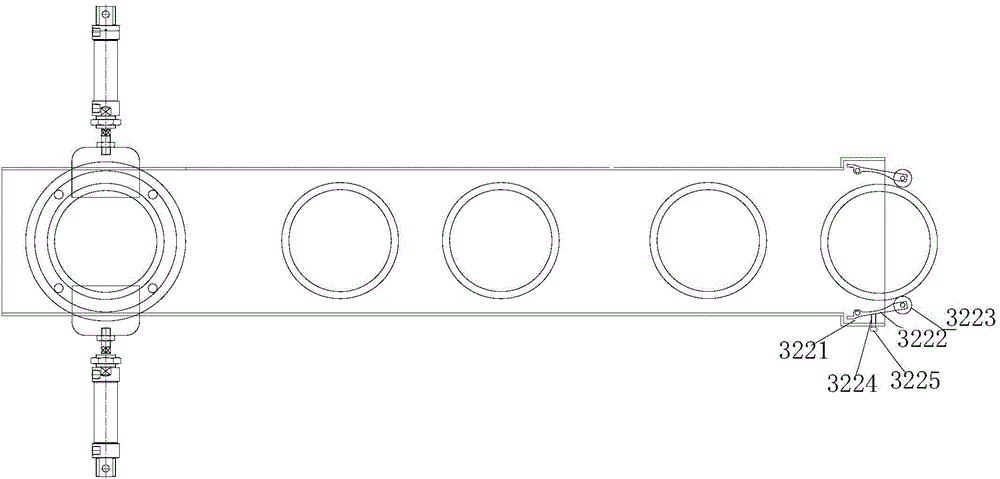

[0030] Preferably, the plastic cover lower cover mechanism 3 includes a cover storage mechanism 31 and a stainless steel slideway 32 below the cover storage mechanism 31, and the cover storage mechanism 31 is several stainless steel rings arranged side by side up and down and fixed on the stainless steel ring A circular channel formed by surrounding stainless steel round bars; two stainless steel s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com